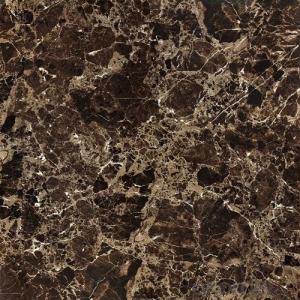

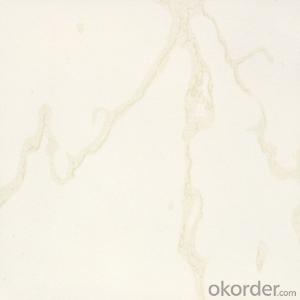

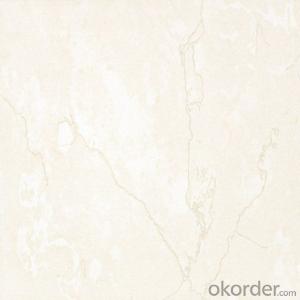

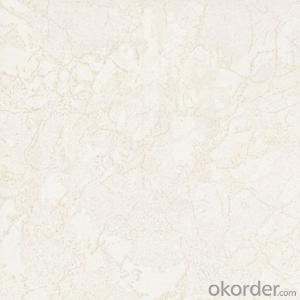

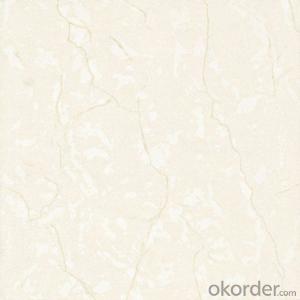

Polished Porcelain Tile Soluble Salt SA012/013/014

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1267.2

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Brief Introduction

Polished Porcelain Tile Soluble Salt SA012/013/014 is one of the most popular color of Soluble Salt Serie, which is one serie of Polished Porcelain Tile in the present market. Just like other series, it could be used for interior floor for apartment, villa, super market as well as other public areas, due to its being high glossy and clean, homogeneous color shade as well as the reasonable price compared with natural stones.

Product Features

Polished Porcelain Tile, Double Loading

Only Grade AAA available

Strict control on color shade, deformation, anti-pollution, surface glossy degree as well as packing

Competitive price

Standard export packing: Pater Carton+ Wooden Pallet

Product Specification

Tile Type: Polished Porcelain Tile

Quality standard: GB/T4100-2006, ISO13006, ISO9001

Water Absorption Rate: 《0.5%

Edge Straightness: ±0.15%

Wearing Strength: 《1600 mm3

Glossiness: 》 85 Degree

Resistance to Chemical: Class UA

Resistance to Staining: Class 3.

Packing Information (For 27.5 Tons heavy 20’Fcl)

For 600x600mm, 4pcs/Ctn, 40 Ctns/Pallet, 960 Ctns/20’Fcl, 1382.4m2/20’Fcl

Production Line & Package

FAQ

1. For Polished Porcelain Tile, is the 30*60 available?

—— Yes, 30*60 is available. Due to the basic size is 60*60, we need to cut 60*60 tile into 30*60. 6 pcs are packed into one carton.

2. What is the MOQ for this tile?

—— Normally the MOQ is 1382.4 m2 for one 20’ container. To support our clients, we could go with 3 models to fill one container at most.

3. Can we use the carton with our own design and brand name?

—— Yes. Normally we go with Neutral Carton or our Carton with our CMAX brand name. But for carton of client’s own design, the MOQ for one size is 5 containers, due to the carton factory can’t arrange production if quantity is below 5000 pcs.

Why Us:

• More than 9 years tile exporting experience,RMB 200 million sales every year.

• More than 13 years tile factory running-well management experience.

• Excellent quality and Competitive price, OEM is available.

• Widely professional exporting experience all over the world.

Suggestion:

Please kindly check the packages after you receive the goods, if you got wrong products/ quality problem/ short q'ty, please

get back to us as priority. Please note that you need to send us pictures of the defective items concerning this, and we will

consider to replace or refund accordingly.

- Q: Tile 60 * 60 price

- There is no certain price, depends on you to buy a few lines of brand, more expensive first-line brand. Second, depends on what type of brick you buy, such as tiles cheaper, all throwing glaze more expensive.

- Q: How about Tommy Tiles?

- But also if it is a good point on the With Guangdong brick Such as Mona Lisa Marco Polo I hope my answer will help you Give the best answer to an answer

- Q: How to distinguish between true and false tiles

- Can determine whether the factory agent or distributor or sell fake. 2, to see the back of the tile signs and packaging, there are manufacturers logo, there are manufacturers on the packaging and some formal content, such as grade, etc., you can consult the above manufacturers service phone. 3, won the fine heavy brick, you can look at its work and so on, the intention to feel, I hope you can buy assured brick, decoration smoothly.

- Q: I want to install wood look laminate flooring. I have a sliding glass door with metal frame. I can‘t put shoe molding around it since it‘s metal so what do I do? Also, with porcelain tile, do I create some type of frame around the tile with real wood or is there a transition for this.

- For the tile you can get metal edging to use as a transition from the tile to whatever else; the shape of the edging is determined by what it butts up against. Several different shapes are available in various colors. It is mortared in under the tiles to form a finished edge. You can get this stuff at Home Depot in the tile department.

- Q: After laying the tile I noticed that they have a hazy patch which appears unglazed in each tile. Is there a substance that I could apply to give the tiles an even look?

- Glazed porcelain or a true porcelain? If it is a glazed porcelain ( my guess) and you have spots that are un glazed, this is a manufacture defect and the tile (s) will have to be replaced. If this is just a grout haze there are cleaning methods you can do to get the grout ff. But other than that, there is nothing you can do other than replace tiles. If you bought the tiles at a regular flooring store, the manager or sales rep from that tile maker should be sent out to inspect it. With out knowing more its hard to say what else you can do. Any questions you cn e mail me through my avatar and check my qualifications there. GL

- Q: I need to know the quality of all different kinds of tiles. Please name the tile and the list or features of it so I can see which tile has the best and worst quality! THANK YOU!

- Tiles that are glazed on the top of a terra cotta base are cheapest. If the glaze chips, the underlying terra cotta base will be an eyesore. Tiles that are ceramic all the way through are best. Look for tiles that are the same color underneath as the glaze is on top. Tip: If you can convince the tile setter to set them diagonally, you will be forever grateful. It costs more, but it's worth it. Honest.

- Q: im kinda changing the tiles in my house and I need some help choosing between white horse tiles or niro granite tiles for the dining hall and toilets.Which one do you think is better?If possible can you please tell me why?it is okay if you don‘t.thanks.hope you can help me

- Hello, I assume your question is trying to distinguish the differences in the companies or the difference between ceramic and granite tiles? lol, if its regarding difference between ceramic and granite tiles I can give a little insight: ceramic tiles are usually cheaper and maybe weigh about 1/5th of the weight of granite. Granite is very hard to cut, since it is stone. Its harder to cut granite than it is to cut marble per say. Granite will last a whole lot longer and won't scuff up or crack if you drop something on it, like ceramic tile would. You have pro's and cons with both products. I have replaced floors using both tiles and although the granite tiles look better and are more classic looking, the ceramic tile is much easier to put down. Cost comparison on regular granite in the state of Georgia from Floor Decor runs about $2.00 sq foot. Where as in ceramic tile ranges from about .75 to 2.50 per foot depending on style etc... Hope this helps you with your question. As far as the two different companies I am not familiar with them. Best of luck!

- Q: I have several boxes of wall tile and I would like to use some on a floor. Is this okay? What is the difference?

- No because when wall tile gets wet it gets very slipery. You would be creating an ice scating rink.

- Q: We grouted the tile, and also had a border tile up.. the border is decorative and has some texture to it.We did wipe off the excess as we grouted. The next day tho, my brother sealed it, before making sure all the dust was off.. now there is some grout dust sealed onto the border tile. I scrubbed with a toothbrush, and managed to get some of it off.. but not all.Is there anything I can do to remove the grout, or even the seal, without ruining the finish on the tile??

- I tile every day of my life, and I empathize. Too bad the dust wasn't wet mopped away completely. I'd find out what the ingredients of the sealer are, and try to find a chemical designed to dissolve it. Below is a general link with some topics regarding your issue. I guess what I'm more confused about is that the sealer was apparently applied to the entire surface, not just the grout? Steven Wolf 45 plus years as a contractor

- Q: Wondered what people‘s experiences were of the above in kitchens. The kitchen leads out into the back garden so the floor will be walked on an awful lot. Would flooring last or look as good after a year or would tiles be the way to go. Any info would be great before I make a purchase.Thanks

- If you compare cost, tile flooring seems costlier than wooden flooring. The cost depends entirely on the quality of the materials. Sometimes, wooden flooring can be costly too if the woods are of top quality. And if you compare the life of wooden and tile flooring, I believe it depends on how you use and care. If you can care it properly, it will last longer. So, overall I would say that both the materials can be good for the kitchen whether it’s wooden or tile flooring. It depends on your requirement such as the kind of style or decoration you want in your kitchen.

Send your message to us

Polished Porcelain Tile Soluble Salt SA012/013/014

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1267.2

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches