PDC Thrust Bearing used in downhole dynamic drilling tools

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.PDC thrust bearing is widely used in downhole dynamic drilling tools, it is with high hardness and longer life charateristics. It can be in operation at super high temperature (currently the highest temperature is 233℃)and it can hold higher axial load. One pair PDC thrust bearing includes upper ring and bottom ring,one piece PDC thrust bearing includes two part: tungsten carbide ring and PDC compact.PDC material friction coefficient is very low so that it can not be affected by chemical material.

2.PDC thrust bearing is made with standard brazing technology, its compact surface hardness is very high, the contact surface flatness of PDC compact is very low and difficult to manufacture. Few factories in China could overcome this problem.

3.With many times improvement Research and development, we use more advanced welding and grinding technology, has overcome the flatness problem of PDC compact contact surface, make the contact surface flatness less than 0.02mm so that strongly improved PDC thrust bearing service life. Our technology for manufacturing PDC thrust bearing has reached the international advanced level in the industry.

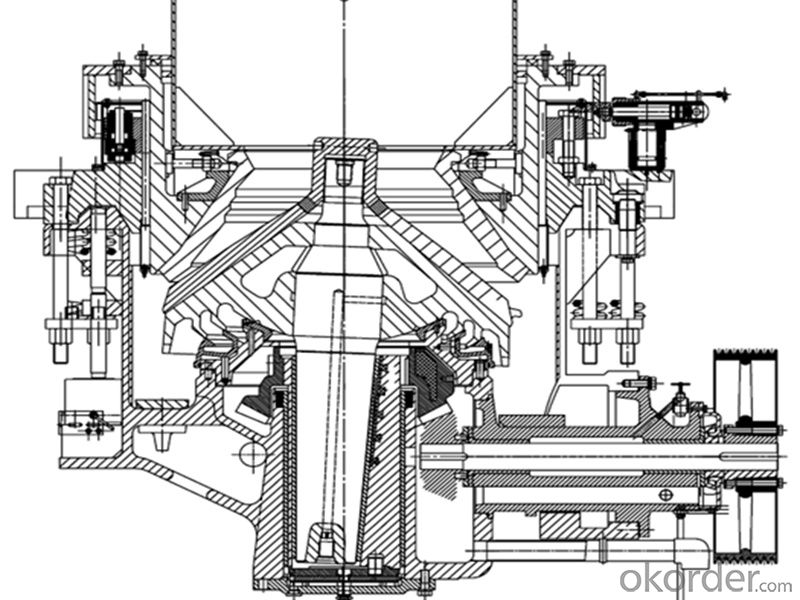

4.Pictures

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q:I feel different from other factories, ah, there is no pungent smell!

- You go to Harbin axis Ji'nan company to ask, they are the factory's direct center, can solve your problem

- Q:A bearing assembly that can withstand greater torque (other requirements are not required and the axle is cantilevered)

- In addition, do not know in the operation process with no axial force, you can use two sets of spherical roller bearing.

- Q:What's the bearing fillet of the 7003C? Do other bearings have the same fillet?

- Angular contact ball size and chamfer can be downloaded by gb/t292 queryEach type of bearing has a GB definition, outline size and chamfer, and you can search for the use of GB

- Q:In addition there is no other original bearing high speed bearing deposit in 50 seconds or more for the name?

- This is bound to have a lot, you can refer to the bearing of a book, can be used for industrial bearings, FAG, SKF, NSK and so on imported bearings, regardless of speed or accuracy requirements, the total requirements of wear one for you.

- Q:What are the advantages of ceramic ball bearings versus other bearings?

- 1, insulation bearings;2, light weight, less heat, you can have higher working limit speed.

- Q:1.6 of the two case K2 rear wheel bearings are the same as the other K2?

- I would like to ask whether you have seen bearing down bearing types and brands,

- Q:Machine specific, please describe the specific points

- Many types of bearings. According to the direction of the load it can withstand can be divided into: the radial bearing, also known as radial bearings, bearing radial load. The thrust bearing, and thrust bearing, bear the axial load. The radial thrust bearing, also called centripetal thrust bearing under radial load and axial load at the same time according to the nature of work. The friction bearing can be divided into different sliding friction bearings (the sliding bearing) and rolling friction bearings (the rolling bearing) two categories.Angular contact bearings: ball and raceway nominal contact angle greater than 0 degrees, the rolling bearing and less than 90 degrees. At the same time can bear radial load and axial load. Can work at a higher speed. The larger the contact angle, the axial bearing capacity is higher. The high precision and high speed bearings usually take 15 degrees contact angle in the axial direction. Under the action of force, will increase the contact angle. The axial load of ball bearings can only bear a direction, in radial load, will cause additional axial force. The axial displacement and can limit shaft or shell in one direction. If the duplex mounting, so that a pair of bearing outer ring relatively, i.e. the wide end of the wide end, the narrow end face with narrow end. So to avoid the additional axial force, but also in the two direction of the shaft or shell limit in the axial clearance range.

- Q:Bearing, in addition to interference, excessive, gap three kinds of co-ordination, there are no other coordination?

- Not only bearings, but only three of these combinations

- Q:I want to use laser displacement sensor to measure the displacement of the slider. I hope the master will recommend a sensor.

- Are you using them on machine tools? If so, I know that the jack sensor has something for you. You can look them up at their website first.

- Q:Must the axle neck fit with the bearings? Is there anything else you can use? Or nothing?

- The rotating part of the supporting shaft must have a bearing, either a rolling bearing or a sliding bearing.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PDC Thrust Bearing used in downhole dynamic drilling tools

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 10000 set/month

Offcanvas right

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords