Casing antichafe machine pipe wear in the drill pipe joints

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Introduction:

The loss of the drive pipe wear in the drill pipe joints can’t be ignored during the processing of the deep mine, ultra-deep well, horizontal well and directional well. Using casing abrasion can effectively reduce the wear of drill pipe joints and lower the friction torque during the time of the drill pipe rotate. The both ends of the casing abrasion is conventional drill buckle, it can be easily individual or assembly used according to the requirement of well drilling.

2.Casing antichafe machine characteristics

.Adopting cemented carbide bearing, drilling fluid lubrication, long life, low friction coefficient.

.Made by high strength alloy steels, high strength, safe and reliable.

.Outside sliding sleeve is used low hardness alloy and antifriction composite.

3.The basic size of antichafe machine

Type

| The whole length mm | OD

| Nozzle

| Both ends screw

| Lubrication method

| Strength rank

|

Ф146 | 760 | 148 | 68 | NC38 | drilling fluid

| The same as the intensity of the drill pipe joints

|

Ф197 | 840 | 197 | 75 | NC50 | drilling fluid

| |

Ф203 | 840 | 203 | 75 | 5½"FH | drilling fluid

| |

Ф206 | 840 | 206 | 75 | NC50 | drilling fluid

| |

Ф240 | 840 | 240 | 85 | 5½"FH | drilling fluid

| |

Ф260 | 915 | 260 | 85 | 5½"FH | drilling fluid

|

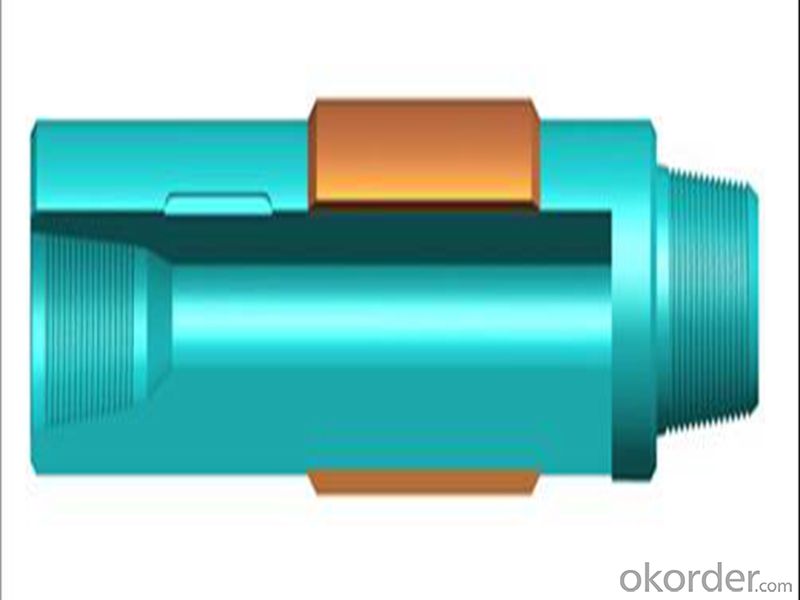

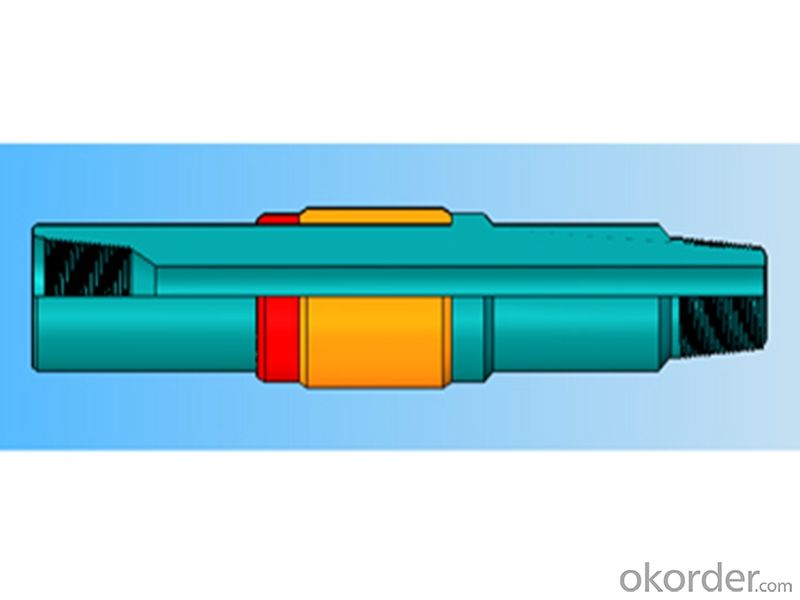

4.Pictures

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: A bearing assembly that can withstand greater torque (other requirements are not required and the axle is cantilevered)

- Torque? Bearings are not used to bear torque, mainly to bear axial or radial load

- Q: What does 7 represent? What does the rest represent? If 7 is changed into other numbers, what does it represent?

- B stands for angular contact bearings with an angle of 40 degreesE stands for internal design and has been optimizedCB represents the universal set of single row angular contact bearings in the face, back to back, clearance for ordinary group

- Q: I worked in my company bearing the main agent of Harbin SKF FAG NSK NTN the other bearing which have the quality in the first place absolutely genuine fake a lose ten

- What is your department, I also do bearings, practitioners have been 20 years, I hope to exchange. Please leave a contact information.

- Q: What's the bearing fillet of the 7003C? Do other bearings have the same fillet?

- In GB/T292-1994 standard, the fillet of 7003C is r0.15 to r0.3; in GB/T292-2007 standard, the fillet of 7003C is r0.10 ~ r0.3.

- Q: How can the rod joint bearings be connected with other parts?

- Threaded, rod end joint bearings with internal and external thread points, used in different workpieces. The screw thread is generally used on the fixed shaft, and then the rotating shaft passes through the fish eye bore to form a movable joint part.There is no specific picture, you can refer to the network of rod end joint bearing sample diagram, imagine.

- Q: It is a special household pump, round about half a meter longOpen when the leakage coil, and the three set of bearings replaced, can not use it, has been tripped, how the more repair the worse? Is it true that the repair shop is intentional?

- Hello, according to your description:Water pump bearings only a bad disk, then only need to replace a plate of bearings, the other two plates do not need to replaceI hope my answer can help you, what questions please continue to ask questions, thank you for your adoption!

- Q: Is there any difference between plain bearings and other bearings?

- The biggest difference between the sliding bearings is linear motion, and the other bearings do circular motion.

- Q: Characteristics of cross roller bearings

- Cross roller bearings, with the inner and outer ring divided into, roller and interval retainer, and cross roller collar fixed together, separated from each other to prevent the installation of cross roller collar simple operation. Because roller cross arrangement, so only 1 sets of cross roller collar can withstand various direction load, compared with the traditional model, increase the rigidity of 3~4 times. At the same time, because the cross roller bearing inner ring or outer ring is a two division structure, the bearing clearance can be adjusted, even if the preload is applied, high precision rotary movement can be achieved.1, with excellent rotation accuracyThe internal structure of cross roller bearings is made of 90 degrees vertical cross arrangement of rollers,The roller is provided with an interval retainer or an isolating block, which prevents the tilting of the roller and the grinding between the rollers. In addition, the phenomenon of side contact or locking of the roller can not occur; at the same time, because the inner and outer ring is a segmented structure, the clearance can be adjusted, and even high-precision rotation can be obtained even if the preload is applied.2. Simplify the operation and installationThe outer ring or inner ring divided into 2 parts is fixed together after the roller and retainer are mounted, so the installation is very simple.3, bear larger axial and radial loadBecause the rollers are arranged perpendicularly to each other on the rolling surface of the V groove on a 90 degree angle.

- Q: How about the quality? Have informed friends to help refer to

- It should also be right, and they had 2 small, they are looking for with the goods, the boss looks like Shandong, pretty cool gas.This one?

- Q: What is the cause of a large bearing vibration of a turbine and other bearings?

- There is a lot of vibration in a single bearing, and it needs to be analyzed in combination with the data on the disk. I hope you find out the reason at an early date.

Send your message to us

Casing antichafe machine pipe wear in the drill pipe joints

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords