X-over sub for for conversion and connection of drill stem component in petroleum

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Xover sub acts for conversion and connection of drill stem component in petroleum, natural gas and geology drilling work. It is one of the main tools in connect the upper tool and the bottom Hole. It is used mainly for connecting of upper drill tools and lower drill tools during drilling operations when upper and lower buckle type failed to connect during drilling operation.

2.Features:

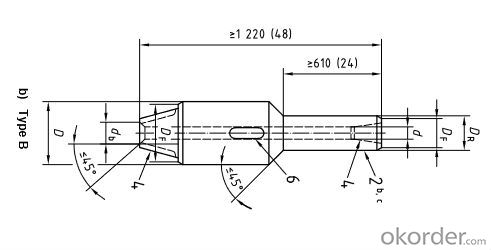

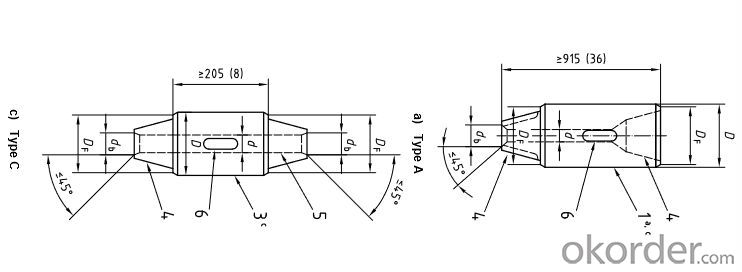

3. The basic structure of the X-over sub

Variety | name

| Upper link

| Lower link

| Type

|

1 |

| Kelly

| Drill pipe joints

| A or B A或B |

2 | drill pipe Cross-over sub

| Drill pipe joints

| Drill pipe joints

| A or B A或B |

3 | Transition Cross-over sub | Drill pipe joints

| drill collar

| A or B A或B |

4 | drill collar Cross-over sub

| drill collar

| drill collar

| A or B A或B |

5 | Borehole Cross-over sub

| drill collar

| drill collar

| A or B A或B |

6 | Faucet Cross-over sub

| Faucet

| Kelly bar

| C A或B |

7 | Salvaging Cross-over sub

| Kelly

|

| C

|

Drill pipe joints

| Fishing Tools

| C |

4.Pictures

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: I need regular manufacturers' agents (with authorized certificates and large scale agents)

- Hello, I do import bearings, have authorization letter, customs declaration, certificate of origin and other relevant informationContact personal data

- Q: Isn't it the middle question or the other question? I'm looking for glfore to do the test. Did anyone do that?

- Possible in the middle. There may be other problems. You can try with them. Excellent

- Q: Are there any differences between bearings used on fans and other ordinary bearings?

- If the model is the same, it makes no difference.From the point of view of the category, there are more taper and more heart in the gearbox;

- Q: I worked in my company bearing the main agent of Harbin SKF FAG NSK NTN the other bearing which have the quality in the first place absolutely genuine fake a lose ten

- Tianjin riside Machinery Sales Co. ltd.. My company's main agent SKF NSK bearings

- Q: It is a special household pump, round about half a meter longOpen when the leakage coil, and the three set of bearings replaced, can not use it, has been tripped, how the more repair the worse? Is it true that the repair shop is intentional?

- Hello, according to your description:Water pump bearings only a bad disk, then only need to replace a plate of bearings, the other two plates do not need to replaceI hope my answer can help you, what questions please continue to ask questions, thank you for your adoption!

- Q: In bearings, why are the flanges connecting the upper and lower cases higher than those of the other bearings?

- If it is understood as the reducer, the upper and lower box connecting the flange (bearing box outside the prominent part), the reason is to prevent the bearings in operation, gear and box friction, damage box, reduce gear life.

- Q: What are the world bearing giants?

- Domestic comparison of large-scale bearing companies, mainly in the following:HRB (Kazakhstan axis) LYC (Luozhou) ZWZ (Wa Zhou) axis Institute of Technology (ZYS)Northwest axis universal bearings, human bearings, Tianma bearings, Xiangyang bearings, Jinxi axle, Longxi bearings, and so onAt present, about eight or nine listed Bearing Enterprises

- Q: What model is used more? What are the prospects for development? Does the price have an advantage?

- There are many manufacturers of this kind of bearings, mostly in ShandongShandong bearing price is very strong, quality is guaranteedInterested, contact information to see personal data

- Q: Bearing, in addition to interference, excessive, gap three kinds of co-ordination, there are no other coordination?

- These three types of coordination, and other coordination is only a different individual name, but the actual situation is the same

- Q: sometimes to the other bearing sliding bearing number, sometimes to the sliding bearing parts inside, why?

- Also called the "Bush", is in the shape of half cylinder tile.

Send your message to us

X-over sub for for conversion and connection of drill stem component in petroleum

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords