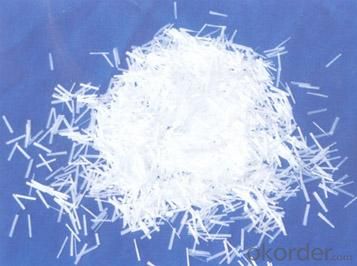

Owens Corning Chopped Strand Fiberglass for BMC

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

Chopped Strands for BMC are compatible with unsaturated polyester, epoxy resin and phenolic resins.

The end-use applications include transportation, building & construction, electronic & electrical, mechanical, and light industry.

2.Product Features

Extremely low resin demand, delivering low viscosity to BMC paste

High impact strength; High LOI rate

High strand stiffness; Compatible with rubber

3.Product Specifications

Property | Fibre diameter | Moisture Content | Size Content | Chop |

(%) | (%) | (%) | (%) | |

Mathods | IS01888 | ISO3344 | ISO1887 | |

3mm | ±10 | ≤3.0 | 0.1±0.05 | 98 |

6mm | ||||

9mm | ||||

12mm |

Special specification can be produce according to customer requirements.

4.FAQ

Packaging:

Each bag can be taken (15-25kgs)。 Could also take a big container bag.

Storage:

Unless otherwise specified, It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

- Q: Production and process of glass fiber reinforced plastics.

- The simplest way is melting the glass and steel and then combining them together.

- Q: How is fiberglass chopped strand incorporated into a composite material?

- Impregnation or infusion is a common method for incorporating fiberglass chopped strand into a composite material. This process involves mixing the chopped strand with a resin, often a thermosetting resin like polyester or epoxy, to form a matrix material. The resin acts as a binding agent, holding the fibers together and providing strength and rigidity to the composite. During impregnation, the chopped strand is evenly dispersed in the resin to ensure full coating and saturation of the fibers. This is typically achieved by mechanically agitating the mixture, such as using a mixer or blender, to ensure a uniform distribution of the fibers throughout the resin. Once the chopped strand is fully impregnated with the resin, the composite material can undergo further processing. It can be shaped into various forms such as sheets, panels, or molded into specific geometries. The material is then cured or hardened, typically through the application of heat or a catalyst, to solidify the resin and create a durable composite structure. The incorporation of fiberglass chopped strand into a composite material offers several advantages. The fibers provide excellent strength and stiffness, thereby enhancing the overall mechanical properties of the composite. They also improve impact resistance, dimensional stability, and resistance to corrosion and weathering. Moreover, the chopped strand reinforces the composite, making it more resistant to cracking and delamination. The fibers also aid in the efficient distribution and dissipation of loads, resulting in a more reliable and durable composite material. In conclusion, incorporating fiberglass chopped strand into a composite material is a crucial step in the manufacturing process as it significantly enhances the mechanical properties and performance of the final product.

- Q: How is the quality of fiberglass chopped strand ensured during production?

- The production process of fiberglass chopped strand incorporates various measures to guarantee its quality. To begin with, strict testing is carried out on the raw materials, including glass fibers, resin, and additives, to ensure they meet the necessary specifications and standards. Throughout the manufacturing process, regular calibration and maintenance of the production equipment are conducted to ensure accurate and consistent outcomes. Close monitoring and control of parameters such as temperature, pressure, and speed are employed to achieve the desired quality of chopped strand. Quality control checks are performed at different stages of production. These checks involve visually inspecting the finished product to identify any defects or inconsistencies. Additionally, samples are taken from each batch and subjected to a range of tests, including tensile strength, fiber diameter, moisture content, and impurity levels. These tests serve to verify the physical and chemical properties of the chopped strand and ensure it meets the required standards. In addition, production facilities often implement quality management systems, such as ISO 9001, to ensure adherence to established protocols and procedures. These systems aid in maintaining consistency, traceability, and continuous improvement in the production process. In conclusion, the quality of fiberglass chopped strand is guaranteed through rigorous testing of raw materials, meticulous control of the production process, thorough quality checks, and adherence to quality management systems. These measures ensure the production of a reliable and consistent product that meets the desired specifications and standards.

- Q: Is fiberglass chopped strand resistant to abrasion?

- In general, fiberglass chopped strand exhibits resistance to abrasion. Fiberglass is renowned for its robustness and sturdiness, granting it exceptional protection against abrasion-induced wear and tear. The interweaving and bonding of the chopped strands result in a formidable and resilient material capable of withstanding abrasive forces. Nevertheless, the precise degree of resistance may vary depending on the precise composition and manufacturing technique employed in the production of the fiberglass chopped strand. It is advisable to consult the product specifications or communicate with the manufacturer to obtain specific details regarding the abrasion resistance of a particular fiberglass chopped strand product.

- Q: What are the health risks associated with exposure to fiberglass chopped strand?

- There are several health risks that can arise from being exposed to fiberglass chopped strand. Firstly, fiberglass consists of small strands of glass that can be easily inhaled if safety measures are not followed. Inhaling these particles can cause irritation in the respiratory system, resulting in symptoms like coughing, wheezing, and difficulty breathing. Extended exposure to fiberglass dust can also lead to chronic respiratory conditions such as asthma or bronchitis. Apart from respiratory issues, fiberglass can also cause irritation to the skin and eyes upon contact. Direct contact with fiberglass particles can cause itching, redness, and rashes on the skin. If these particles come into contact with the eyes, it can cause irritation, redness, and potentially more serious conditions like corneal abrasion. Furthermore, fiberglass chopped strand is often treated with a binder or resin to enhance its properties. These chemicals can release volatile organic compounds (VOCs) into the air, which contribute to indoor air pollution. VOCs can result in various health problems, including irritation in the eyes, nose, and throat, as well as headaches, dizziness, and nausea. Prolonged exposure to high levels of VOCs can even lead to more severe health issues like damage to the liver, kidneys, or central nervous system. To prevent these health risks, it is crucial to take proper safety precautions when working with or around fiberglass chopped strand. This includes wearing protective clothing like gloves, goggles, and a respirator to avoid direct contact and inhalation of fiberglass particles. Adequate ventilation and dust control measures should be implemented to minimize the release of fiberglass dust and VOCs into the air. Regular cleaning and maintenance of the work area also help in reducing the risks associated with fiberglass exposure. Overall, although fiberglass chopped strand has many advantages and applications, it is important to be aware of the potential health risks and to take necessary precautions to safeguard oneself from its harmful effects.

- Q: Can fiberglass chopped strand be used in electrical insulation coatings?

- Indeed, electrical insulation coatings can make use of fiberglass chopped strand. Fiberglass, being a versatile material, possesses exceptional electrical insulation characteristics, rendering it appropriate for a wide range of electrical applications. By incorporating fiberglass in its chopped strand form, coatings can effortlessly acquire reinforcement, thus enhancing their electrical insulation capabilities. The incorporation of chopped strands not only augments the coating's mechanical strength and resistance to cracking, but also furnishes it with thermal stability and resistance to moisture. In conclusion, fiberglass chopped strand stands as a dependable choice to ameliorate the electrical insulation properties of coatings utilized in electrical applications.

- Q: Does fiberglass chopped strand improve the impact resistance of composite materials?

- Composite materials can benefit from the use of fiberglass chopped strand, as it effectively enhances their impact resistance. By incorporating small, randomly oriented fibers into the manufacturing process, the chopped strand reinforces the composite material. In the event of an impact, the fiberglass chopped strand plays a crucial role in distributing and absorbing the force, thereby preventing concentrated damage. Acting as a protective barrier, the fibers disperse the impact energy throughout the composite material, reducing the likelihood of cracks or fractures. Moreover, fiberglass chopped strand also improves the interfacial bonding between the fibers and the composite's matrix, resulting in better load transfer capabilities. This enhanced bonding strength significantly contributes to the overall impact resistance of the composite material. To summarize, the inclusion of fiberglass chopped strand in composite materials greatly enhances their impact resistance by effectively dispersing and absorbing impact energy, preventing localized damage, and improving the overall strength and durability of the composite.

- Q: Is fiberglass chopped strand electrically conductive?

- Fiberglass chopped strand, contrary to popular belief, lacks electrical conductivity. It comprises glass fibers coated with a non-conductive substance, usually a resin, serving as insulation and obstructing the passage of electricity. Consequently, fiberglass chopped strand emerges as an ideal choice for electrical insulation purposes that demand the absence of electrical conductivity.

- Q: Can fiberglass chopped strand be used in the production of wind turbine nacelles?

- Fiberglass chopped strand is indeed applicable for the manufacturing of wind turbine nacelles. It is widely utilized as a reinforcement material during composite manufacturing procedures. The nacelle of a wind turbine is typically composed of a composite material, which encompasses a blend of fiberglass and resin. To enhance the mechanical properties and provide durability and strength to the nacelle, the fiberglass chopped strand is incorporated into the resin matrix. This inclusion improves the overall structural integrity and stability of the wind turbine nacelle, allowing it to withstand the demanding conditions and load requirements of wind turbine operation. Moreover, fiberglass chopped strand possesses the desirable qualities of being lightweight and corrosion-resistant, making it highly suitable for wind turbine applications. Consequently, it is a frequently employed material in the production process of wind turbine nacelles.

- Q: Can fiberglass chopped strand be used in the production of electrical components?

- Yes, fiberglass chopped strand can be used in the production of electrical components. Fiberglass is a versatile material that possesses excellent electrical insulation properties. The chopped strand form of fiberglass consists of small, randomly oriented fibers that can be easily mixed with other materials, such as resins, to create composite materials. These composites can be used to manufacture electrical components like insulators, circuit boards, and enclosures. Fiberglass chopped strand provides electrical insulation, high mechanical strength, and resistance to heat and chemicals, making it suitable for various electrical applications.

Send your message to us

Owens Corning Chopped Strand Fiberglass for BMC

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords