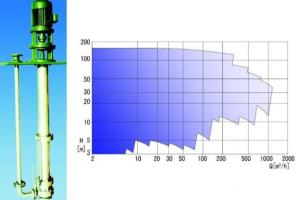

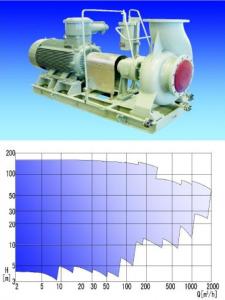

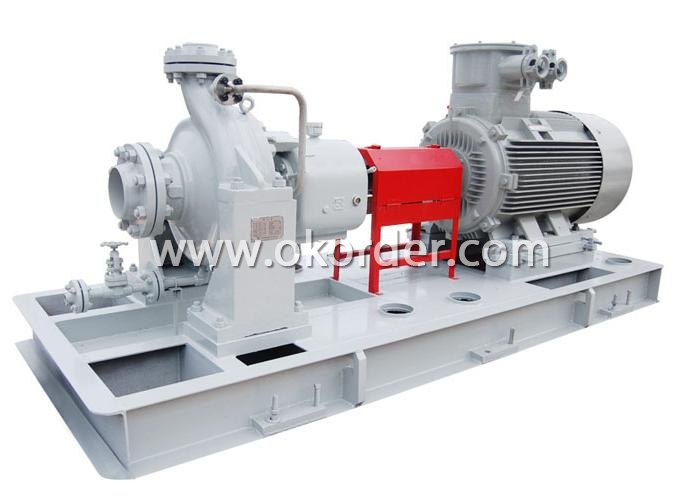

OH2 Centrifugal Oil Pump (ZHY Series)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 Per Month unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OH2 Centrifugal Oil Pump (ZHY Series)

1. Specifications of OH2 Centrifugal Oil Pump:

Capacity: Q = 5~2600 m3/h

Head: H = 15~250 m

Working temperature: T = - 45~450 degree centigrade

2. Application of OH2 Centrifugal Oil Pump:

Petro refining

Petrochemical industry

Low temperature projects

Chemical fiber and common industry process

Power plants, heating systems or air conditioning systems

Environment protection projects

3. Description of OH2 Centrifugal Oil Pump

OH2 Centrifugal Oil Pump with feet, end suction and radial upward discharge, Hydraulic balance provided by front or rear wear rings and balance holes, shaft seal by packing or mechanical seal, connections for cooling, flushing or seal liquid, Pump clockwise rotation viewed from the driven end.

The pump is designed and made under API610, latest edition, and VDMA2497.

Flange is made as per DIN or AISI standard.

- Q: I wonder if the pressure of the pump is not enough. What will happen to the car?

- To see what the situation is, can not run high speed is a performance!

- Q: What's the function of the engine oil pump?

- It's the engine oil! Pump oil onto the moving parts! Play a better lubrication!!It is also beneficial to the full circulation of the oil!!

- Q: The three price difference increases, I want to know the oil induction plug and oil pump parts price about what?

- The three price difference increases, I want to know the oil induction plug and oil pump parts price about what?

- Q: Does the timing of the car run? Does the pump work? Sometimes the car is in neutral, so it runs by inertia. What's the harm to the car?

- If the manual models can be linked to neutral way but now the car is EFI even idling is not fuel-efficient if automatic car driving process is completely not linked to the gap automatic models of the space is just in the car and trailer when used only

- Q: Iveco oil pump driving wheel how down have special tools for heating 200 degrees

- Iveco oil pump driving wheel how down have special tools for heating 200 degrees

- Q: Does the car pump have a strainer?

- The oil pump pit is fixed, but it is very small in the oil pump! You can't see it! Let's see what we can see!

- Q: Engine oil pump is blocked when the chain would ring

- 1, the phenomenon is generally rhythmic sound, the sound is on the side of the camshaft, the noise is more than when the gear meshing uneven sound sharp. At low engine in speed, sound obvious and clear; increase the solar term door opening, the sound increases and becomes messy. In a few cases, a very heavy "click" sound can be heard, as if the camshaft bearings are seriously loose.2, reason oil pump shaft, distributor drive shaft bending or axial clearance is too large: oil pump drive main and driven gear, distributor drive, driven gear, crash or wear and tear deformation.3, check and judge this sound "fire test" test is invalid, you can touch the stethoscope at the lower end of the distributor body auscultation. If the noise is obvious, the body has a slight vibration, can be repeated from idle to low, medium speed throttle test. If the sound changes, as mentioned above, it may be this sound. If you hear a heavy click or click, as if the camshaft bearings are loose and loose, it is possible that the oil pump is broken.

- Q: SUZUKI motorcycle oil pump is not on the oil, the oil circuit is not blocked, to replace the oil pump, or pump is not on the oil

- Pump clearance is large, the car used for several years now, change the oil pump test

- Q: How do you install the pedal motor pump?

- Put the unit on the foundation with anchor bolts, between the base and the base, and use a pair of wedge pads.Release the axle shaft and place on the pump shaft and base with a level gauge. Adjust the level of the machine by adjusting the wedge pad and tighten the anchor bolts properly so as not to move around.Correct the concentricity of the pump shaft and the motor shaft, and allow the deviation of 0.1 mm on the outer circle of the axle shaft; two the clearance of the coupling plane shall be guaranteed 2~4 mm, and the clearance shall be uniform, and the tolerance shall be 0.3 millimeters.After connecting the pipeline and determining the direction of the motor rotation, then coupled with the coupling, and then check the concentricity of the shaft.In the actual test run 2~3 hours after the unit, for final inspection, if there is no adverse phenomenon, that the installation of qualified. Check the temperature and vibration of the bearing during the test run.During installation, all holes in the unit shall be covered to prevent debris from falling into the machine.In order to prevent the sundries from entering the pump, the filter shall be installed on the newly installed pipeline. The effective cross section shall be 2-3 times larger than the cross section of the suction pipe.However, the oil pump rarely fails, generally as long as the opening of the cylinder head, see more fresh oil or start the engine, there is oil jet, indicating the normal operation of the oil pump.

- Q: Single cylinder diesel engine crank bearing lock replacement, cause oil pump wear, replacement. What's the reason for the lack of power after the change?

- The cause of this phenomenon is the severe wear of the crankshaft journal or the smooth failure of the crankshaft journal! You don't know what type of diesel engine, if the oil channel Changchai ZS1110 and 1115 double rolling type words to check the main bearing cap is worn, because the main bearing cap of oil on the road directly to the crankshaft oil supply, after the formation of wear caused by leakage of lubricating oil pressure machine high temperature, bad to smoke. Troubleshooting: check crankshaft and bearing cap for serious wear and tear. Replace if necessary.

1. Manufacturer Overview

| Location | Liaoning,China |

| Year Established | 1990 |

| Annual Output Value | |

| Main Markets | Russia, Iran, north Korea, Vietnam, Sudan |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

OH2 Centrifugal Oil Pump (ZHY Series)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 Per Month unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords