Polyester Short Fiber Needle Punched Nonwoven Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Polyester Short Fiber Needle Punched Nonwoven Geotextile

1. Product Description:

Needle punched nonwoven Geotextiles are made of polyester or polypropylene in random directions and punched together by needles.

Geotextiles has good impermeability and resistance to deformation, which allows geotextiles be widely applied in civil projects for separation,filtration,reinforcement, protection and drainage.

Geotextiles can be used as:

* Filtration or separation layers in civil engineering projects of roads and railway construction;

* Protect layer for geomembranes in landfill construction;

* Coastal defence applications

* Landscaping projects to maintain soil and protect land surfaces and structures from weeds and root growth.

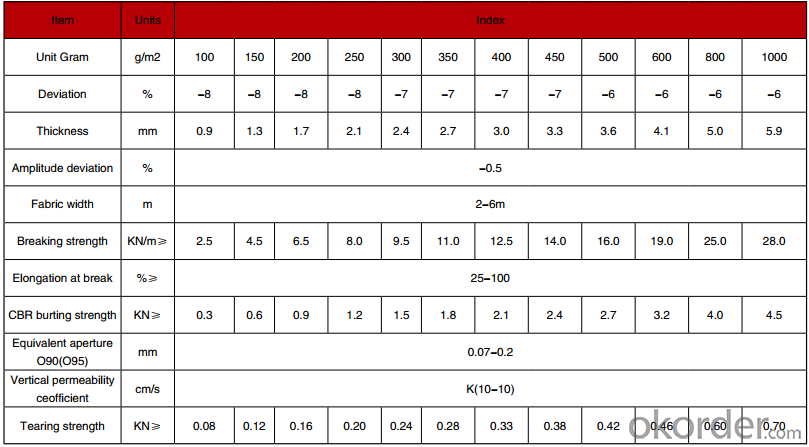

2. Data sheet:

3. Main Features

2) High temperature resistance to up to 230℃ maintaining structure stability and original physical properties;

3) High flat drainage and vertical permeability;

4) High creep resistance;

5) Resistance of erosion of chemicals in soil as well as the corrosion of gasoline and diesel etc;

6) High elongation under certain stress, thus able to adapt to uneven and irregular bases;

4. Packaging & Shipping:

white fabric bag or black PE bag outside or as required.

7 days after received deposite

5. Applications of NON-Woven Geotextile :

Non woven Geotextiles can be widely used in railways, highways, sports halls, ,garbage dump ,dams, hydraulic construction, tunnels, coastal beaches, land reclamation, environmental protection and other projects.

Notes : The specification is based on mass area ratio.

When the actual specification is between adjacent specifications in this table, it is necessary to calculate the corresponding evaluation indicators in accordance with the interpolation method;

If the range in table is exceeded, it is necessary to determine the evaluation indicators through consultation by the supply and demand sides.

6.Pictures

7. FAQ:

Q1: Can you provide a sample for us?

A:Yes,We can send free samples,but customer need to pay the freight.

Q2: What is your minimum order quantity?

A:The minimum order quantity is 5000,but it is negotiable.

Q3:What is your payment terms?

A: T/T,Western Union,L/C.

Q4:What is your delivery time?

A:Production time usually costs 2-20 days.

- Q:What is the role of geotextiles in soil reinforcement?

- Geotextiles play a crucial role in soil reinforcement by providing mechanical strength and stability to the soil. They are used to enhance the overall performance of the soil by distributing loads, preventing erosion, controlling filtration, and promoting drainage. Geotextiles act as a barrier against soil movement and help to improve the stability and longevity of structures built on or with soil.

- Q:The technical parameters of woven geotextile

- Test items / specifications 0400 Remarks breaking strength (longitudinal) KN / m ≥ 17. Breaking strength (horizontal) KN / m ≥ no special requirements by the meridional 0.7 / 1 longitudinal and transverse elongation at break% ≤ 25 vertical and horizontal trapezoidal torn Strength, KN ≥ 0.180.200.270.340.410.480.600.72 vertical and horizontal CBR top breaking strength, KN ≥ 1.41.62.43.24.04.86.07.5 equivalent aperture O95 (O95) mm0.07-0.5 vertical permeability coefficient cm / sK × (10-1-10-4) K = 1.0-9.9

- Q:Filter geotextile, permeable geotextile, seepage geotextile What is the difference?

- The above three products are a product. But is divided into polypropylene staple acupuncture geotextile, polyester staple acupuncture geotextile, filament geotextile. Three categories. Play a major role is good permeability, filtration, isolation performance, construction convenience.

- Q:What is geotextile, what role

- Geotextile is a new type of building materials, raw materials are polyester, acrylic, nylon and other polymer polymer synthetic fiber. In accordance with the manufacturing method is divided into: there are two types of geotextile and non-woven geotextile. Geotextile with anti-seepage, anti-filtration, drainage, isolation, reinforcement, protection, sealing and other functions, it with the conventional masonry and concrete material seepage effect compared to a low investment, simple construction process, short duration Infiltration effect is good, the channel effective use of high coefficient. Water conservancy engineering dams and slope protection filter, channel isolation, seepage control; road, railway, airport runway foundation isolation, filter, drainage, slope, retaining wall and road reinforcement, drainage; , Geotextile has been widely used in the field of infrastructure construction, and has been gradually applied in the field of infrastructure construction, and the use of geotextile In a wider area.

- Q:Nail cave geotextile with a nail where?

- Hardware market can be nails, I professional production geotextile geomembrane and other geotechnical materials, wish smooth

- Q:What are the considerations for geotextile selection in road rehabilitation projects?

- There are several considerations for geotextile selection in road rehabilitation projects. Firstly, the geotextile should have the appropriate tensile strength to withstand the anticipated loads and stresses in the road structure. Additionally, it should have the proper permeability to allow for effective drainage and prevent water accumulation. The geotextile should also be resistant to chemical degradation and have good durability to ensure a long service life. Finally, factors such as cost, availability, and ease of installation should also be taken into account when selecting a geotextile for road rehabilitation projects.

- Q:What are the different design considerations for geotextile applications?

- Some of the different design considerations for geotextile applications include the type and strength of the geotextile material, its permeability and filtration characteristics, its durability and resistance to degradation, the required tensile strength and elongation properties, as well as its installation and maintenance requirements. Other factors to consider include the anticipated loadings and stresses on the geotextile, the expected lifespan of the application, and any specific project requirements or environmental considerations.

- Q:What is the difference between nonwovens and geotextiles? What is the difference between geotextiles and nonwovens?

- Geotextile is divided into two non-woven geotextile and woven geotextile, non-woven geotextile and acupuncture and spunlace, staple fiber and long fiber. Nonwovens means that the manufacturing process does not require weaving. Geotextiles are used for geotechnical engineering. Geotextile is part of the textile does not require the manufacture can be made, called non-woven geotextile. Non-woven fabrics can be used very broad, like we use the heart of the soft wipes, are non-woven, as well as the hotel put the shoes of the shoes, but also non-woven.

- Q:Can geotextile skin be connected?

- Geotextile skin can be touched. Geotextile production of raw materials is polyester fiber, polyester has been widely used in daily life. Such as clothes are also a lot of polyester material. So do not worry, geotextile is not harmful to the human body.

- Q:Can geotextiles be used in underground construction projects?

- Yes, geotextiles can be used in underground construction projects. They are commonly used to separate different soil layers, provide filtration, drainage, and erosion control. Geotextiles can also enhance the stability and strength of the underground structures by providing reinforcement and preventing soil movement.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Polyester Short Fiber Needle Punched Nonwoven Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords