Msds Refractory Ceramic Fiber Blanket

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Grade: | COM (Common) | Application: | Refractory | Thickness: | 12.5,25,50 |

| Width: | 600,610 | Length: | 3600,7200 | Chemical Composition: | Al2O3 |

| Ultimate Strength (≥ MPa): | 80 | Working Temperature: | 1400 | Fiber Diameter: | 2.6M |

| Shrinkage (1800 ℉, 3h): | 7 | Thermal Conductivity: | 0.06-0.36 | Density (kg/m³ ): | 96 |

| Model Number: | YESO blanket | Brand Name: | Place of Origin: | (Mainland) | |

| Color: | white | Density: | 96/128/160 | Certification: | ISO9001 |

| Melting point: | 1700 | Length for fiber: | 2600kg/m3 |

Packaging & Delivery

| Packaging Detail: | CARTON+PALLET |

| Delivery Detail: | 7 DAYS |

Specifications

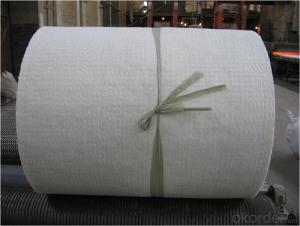

Msds Refractory Ceramic Fiber Blanket

Work temperautre:1000-1600C

Density:96/128/160kg/m3

Color:White

Msds Refractory Ceramic Fiber Blanket

Description: Yeso ceramic fiber blanket is made of special ceramic long-fiber that is produced by the melting of very pure raw materials in double surface meeding process with out binders and with good stability in a large range of temperature. The process of double surface need increasing interweaving and tensile strength.

Characteristics Typical Applications

Excellent thermal stability Joint sealing and filling insulation

Excellent chemistry quality Fiber composite(grinding parcel)

Resistance to burning Internal and external lining

Low thermal conductivity Structure refractory and sponging sounds

Low thermal capacity Materials for hot filtration

Good insulation Raw material for further producing

Good obstructing voice and mechanism strength

Low shrinkage

Good springiness for fibers

Convenient producing and installing

Physical Data

Descriptions | YESO1260 | YESO1425 | YESO1500 | YESO1600 | ||

Classification temperature(°C) | 1260 | 1425 | 1500 | 1600 | ||

Melting Point(°C) | 1760 | 1700 | 1760 | - | ||

Color | White | White | Green-blue | White | ||

Average diameter for fiber(m) | 2.6 | 2.8 | 2.65 | 3.1 | ||

Length for fibers(mm) | 250 | 250 | 150 | 100 | ||

Density for fibers(kg/m³) | 2600 | 2800 | 2650 | 3100 | ||

Chemical compositions | Al2O3 | 45 | 35 | 40 | 72 | |

SiO2 | 54 | 49.6 | 57.8 | 28 | ||

ZrO2 | 15 | |||||

Cr2O3 | 1.8 | |||||

Standards | ||||||

- Q: Slag ball content of ceramic fiber material?

- Slag ball content of ceramic fiber material?The content of 0.25mm foreign size > slag ball control in less than 5%, while domestic due to fiber manufacturing technology limit, content of slag ball control in less than 15%[1], which is nearly 1/8 fiber products in slag ball content twice as high than abroad. Therefore, in determining the bulk density of ceramic fiber products, we should give full consideration to the amount of slag ball.

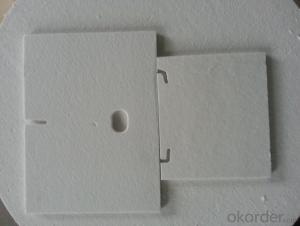

- Q: Who can help me introduce the principle of vacuum forming of ceramic fiber board? Thank you very much.

- Product Description: with stable performance, long fiber and tensile strength, less slag ball, high thermal stability, white color and so on. The classification temperature is 1050-1600 degrees centigrade. It is the preferred material for the production of fiber textiles. It is also an ideal material for sealing, filling and heat insulation in high temperature environment. Features: low thermal conductivity, low thermal capacity, excellent chemical stability, corrosion resistance, excellent sound absorption property, excellent thermal stability. Typical applications: raw materials for industrial ceramic fiber wet products; raw materials for ceramic fiber unshaped products; high temperature kilns, heating devices, wall linings, gap filling materials, etc.. Two, ceramic fiber blanket Product Description: white color, regular size, set fire, heat insulation, insulation in one. Free from any binding agent. In the neutral and oxidizing atmosphere, the tensile strength, toughness and fiber structure can be maintained for long term use. The temperature is 950-1400 centigrade.

- Q: What is the process of producing ceramic fiber mats?

- Specifications:Diameter 10mm-- infinityProduct features:1) the continuous use temperature can reach 1000 DEG C, and the service temperature can reach 1260 DEG C for a short time.2) has good acid and alkali corrosion resistance and aluminum, zinc and other molten metal melting ability.

- Q: What is ceramic fiber?

- 1, ceramic fiber is a fibrous lightweight refractory material, has the advantages of light weight, high temperature resistance, good thermal stability, low thermal conductivity, specific heat and resistance to mechanical vibration, and thus in machinery, metallurgy, petroleum, ceramics, glass, electronics and other industries have been widely used.2, ceramic fiber products is a good refractory. The utility model has the advantages of light weight, high temperature resistance, small heat capacity, good insulation and heat insulation performance, good high-temperature heat insulation performance, no toxicity, etc..3, light quality, good heat insulation performance, good thermal stability, good chemical stability, easy processing and convenient construction. It is neither wear-resistant nor collision resistant, can not resist the erosion of high-speed airflow, and can not resist the erosion of molten slag.

- Q: What is the customs code for ceramic fiber products?

- The customs code should be 6914.9000Specific can be seen by the Chinese customs published in 2005 edition of import and export commodity names and codes, thirteenth and sixty-ninth chapters, ceramic products, P166-168 pages.

- Q: What is the difference between the national standards for ceramic fiber products and ordinary aluminium silicate?

- Generally high alumina content, iron oxide and other impurities of low fiber products are pure white, the introduction of chromium oxide fiber is sold with milk yellow tone color. The average diameter of ceramic fiber products (aluminium silicate fiber products) is 22 - 33 microns. High fiber, small density, low thermal conductivity, high temperature. If the fiber is coarse and dense, the use is not satisfactory. The thermal stability index of ceramic fiber products (aluminum silicate fiber products) is more important. The range of Al2O3SiO2 fiber contraction in various products of 1260 C line is 35 - 88%. The amount of shrinkage is also directly related to thermal stability. Ceramic fiber products (aluminum silicate fiber products) as ceramic fiber products (aluminum silicate fiber products) with low thermal conductivity, low density, light weight, light steel frame are used in the design and construction of kilns supporting structure, so that the development of ceramic kiln kiln into the "lightweight" era. The fiber has small heat storage and is suitable for quick heating and cooling firing.

- Q: What ceramic fiber profiled products are needed in steel mills? What's the name?

- Ceramic fiber and nano heat insulation board are used for heat insulation, and in the steel plant are generally used for ladle, tundish insulation, and now can also be made of nano insulation products special-shaped products.

- Q: Refractory ceramics and other refractory materials manufacturing is a big industry?

- Also belong to the building materials industry, glass industry and other industries, are Rong Sheng refractories industry ah.

- Q: The characteristics of ceramic fiber paper

- There are a lot of ceramic fiber paper called, some people call the fire-resistant fiber paper, insulation paper, aluminum silicate fiber paper, ceramic fiber paper is made from high purity ceramic fiber production, used in the field of high temperature insulation, advanced production technology makes the fiber distribution is very uniform, density and volume of paper can be strictly controlled.There are three kinds of ceramic fiber paper: standard ceramic fiber paper, high alumina ceramic fiber paper and zirconium ceramic fiber paperCeramic fiber paper features: low heat capacity, ground heat conductivity, good electrical insulation performance, excellent mechanical processing performance, easy to cut, strong and tear resistance; high flexibility; low slag ball content

- Q: ceramic fiber

- Advantages of ceramic fiberRefractory ceramic fiber material is a lightweight and efficient thermal insulation material. It has the following advantages over traditional heat insulation materials:Ceramic fiber as lining, low volume density: ceramic fiber lining than light heat insulation brick lining light more than 75%, lighter than light castable lining light 90% to 95%. If using fiber lining, it can greatly reduce the steel structure load and prolong the service life of the furnace.The heat capacity (heat storage capacity) of ceramic fiber lining is low: the heat capacity of ceramic fiber is only about l/10 of light heat resistant lining and light castable lining, and the heat capacity of lining material is proportional to the weight of lining. Low heat capacity means the furnace in the reciprocating operation absorb less heat and heating speed, greatly reducing the operational control of the temperature in energy consumption, especially for heating furnace and furnace, furnace shutdown has obvious energy saving effect.Ceramic fiber lining: low thermal conductivity of ceramic fiber lining in the average temperature of 400 degrees, the thermal conductivity is less than 0.1w/mk, the average 600 degrees less than 0.l5 w/mk, average 1000 degrees less than 0.25w/mk, about l/8 as a lightweight clay brick, lightweight refractory lining l/10, adiabatic effect.The construction of ceramic fiber lining is simple: no expansion joints are needed during construction, and the construction personnel can be started after the basic training. The technical factors of construction have little influence on the insulation effect of the lining. Ji'nan Sheng Yang

Send your message to us

Msds Refractory Ceramic Fiber Blanket

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords