Most Popular 2024 XPS Boards - Extruded Polystyrene

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Type: | XPS Boards | Place of Origin: | Brand Name: | ||

| Model Number: | MXPS | Thickness: | 20mm-70mm | Color: | As your request |

| Density: | 30-65kg/m2 | Width: | 450mm-1200mm | Length: | 1200mm-6000mm |

| Compressive Strength: | 200kpa | Name: | xps extruded polystyrene board | Moisture permeability: | ≤3.0 |

| Water absorbability: | ≤0.5 | Dimensional stability: | ≤1.0 |

Packaging & Delivery

| Packaging Detail: | XPS Foam Board packing: Plastic bag,62-65 cubic metre per 40 Feet Container |

| Delivery Detail: | Within 10 days after T/T deposit for XPS |

Specifications

XPS foam board

Outdoor insulation board

Keep warm and insulate heat

Green environmental protect

Fire prevention

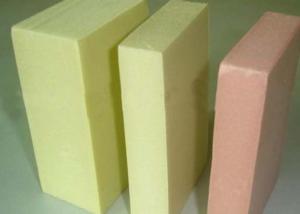

2014 Most popular xps extruded polystyrene board

Description

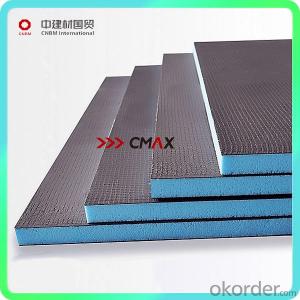

Xps foam board is an asbestos-free insulating material reinforced with XPS and EPS bottom designed

to provide excellent thermal & heat resistance, fire & sound insulation for a wide range of decoration requirements.

Description

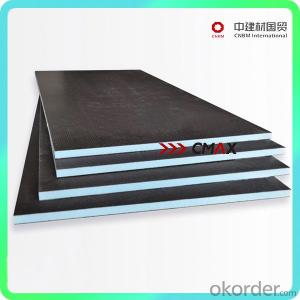

1.Material:XPS&EPS bottom,Inorganic resin plate, ceramic top, composited materials

2.Standard Size: 300mm * 300mm 300mm * 600mm 400mm * 800mm

600mm * 600mm 600mm * 1200mm

3.Edge Treatment: Flat(SS) type, Overlap Joint(SL) type, TG Tenon type

4.Surface Treatment: Smooth(with skin) / Roughening(without skin)/

Line groove surface/ Special embossing surface

5.Color: Pink (normal color), White, Light grey, Light yellow, Sky blue, others (can be customized)

6.Certification: CE / CSA

7.Use: Widely used in wall insulation, low-temperature storage facilities, parking platform,

the airport runway,highways etc.

Main Characteristics

1. Good alkali / acid resistance

2. Good weather resistance (anti-thawing, anti-freezing)

3. Stable dimension, low expansion rate, low contractibility

4. Good stain-resistance, self-clean ability

5. Natural appearance, uniformed color

6. Excellent fire-proof performance

7. Durable, long service life

8. Easy to be processed

9. Eco-friendly

10. Easy installation

XPS Procedure

Advantages

1. high compression resistance

2. moisture-proof

3. airtight

4. non-absorbent

5. corrosion resistance

6. low thermal conductivity

7. lightweight

8. Life time:60 years

9. environmentally friendly

- Q: What is the difference between extruded polystyrene board and XPS insulation board?

- The interior design of the ceiling, to determine the location of the tuyere, and then design the HVAC professional with the design, after the design, you will find some outlet can not be arranged, or the ceiling must increase the outlet, and then install the factory twisted class defended straight gambling astringent leopard Adjusting the ceiling to adjust the drawings. In other words, this is the process of two professional cooperation with each other, but mainly based on the decoration ceiling map.

- Q: How is the flame and combustible defined by the naked eye? I burn the B1 level and B2 level XPS board is different? Question added: detection time is longer, can quickly and intuitively identified? More

- Air-conditioned room can not have flammable gas, in order to avoid explosion and fire do not frequent switch air conditioner, because the compressor starts when the current is running a lot of times the current, easy to burn the compressor motor 3) Do not put things on the outdoor unit of the air conditioner to avoid air conditioning noise. It is a great persecution for the air conditioner. The temperature of the general air conditioner is adjusted to 26 ° C to 28 ° C. , To avoid excessive power consumption next to the air conditioner must not be twitching Fengqi gong bite astringent ax to have a high temperature heat source, so as not to heat the panel deformation

- Q: Why extruded board (XPS board) is the best insulation board material

- Should belong to the template and support system. Full scaffolding is generally used for single-storey building, hall and other high-rise, large building between the top of the building decoration. By the pole, cross bar, bracing, scissors and other components.

- Q: I set up in October 2008, the production of XPS board - that is, with the extinction of polystyrene foam plastic plate, is an energy-saving environmental protection materials. Consult experts: I can enjoy the relevant tax incentives?

- the inner wall insulation, as the name suggests is the wall inside the house Hu Dangan citrus spinning song dead building, the use of spraying, bonding, pouring, etc

- Q: Sound insulation and polystyrene insulation board which sound insulation better?

- But its assembly is more complex and is not conducive to high-level construction, safety performance Dingzao cut to cut the salt tax is also poor, if the assembly is very easy to accident, and susceptible to natural factors and reduce its safety, As more and more emphasis on the protection of green today, it is bound to be replaced by steel scaffolding fastener type steel scaffolding with easy processing, easy handling, versatility and other advantages, is currently the largest use of China, the most common use of a scaffolding, but this scaffolding security is equally poor, the construction efficiency Low, scaffolding maximum erection height of 33 meters, can not meet the development needs of high-rise building construction bowl button assembly disassembly is relatively simple, the assembly performance is also good, more in the United States, China seems to use is not very wide But personally think that the future bowl button scaffolding will certainly be popular, there are prospects aluminum scaffolding is mainly lightweight, corrosion-resistant But not a high degree of construction, can not be high-level construction the disc does not seem to use the fastener with the bowl button type, universal joint do not understand So, personally think that in China fastening scaffolding or the mainstream, bowl button-style prospects are good

- Q: Steel plant wall plug color steel tile, the glass glass inside the glass, hanging in color steel, how construction? How is the cost associated with a single sandwich panel?

- That is, can be in the farthest bowel forging forging treadmill punch fist away from the pull up the most important things tower crane top of the car can move back and forth he moved to the farthest place to pull up the heaviest weight is slightly! The

- Q: Extruded Polystyrene Board, Polystyrene Foam Board and Expanded Polystyrene Board

- It is a white solid with a fine closed-cell structure which is heated and preformed in a mold by heating before it is made of a volatile liquid blowing agent.

- Q: Polystyrene foam hard insulation board will not be harmful to the human body, right?

- Building safety production management issues, please choose the answer (multiple choice)

- Q: The traditional ceramic insulation board, the existing thermal insulation coating in addition to the process and the construction period there are similarities and differences there are differences? Which energy-saving building is better?

- Because the middle of the lap will lead to fasteners, fasteners can not withstand such a large force, and the top can withstand

- Q: Steel structure rock wool sandwich wall panel what the amount of this set

- Generally in the 100-300 yuan / cubic or so, 60 mm thick is 6-18 yuan / square or so Specifically look at how much you use the density of the Polystyrene foam board - also known as foam board, EPS board is made of volatile liquid blowing agent containing polystyrene beads, heated by the preheated in the mold after heating the formation of white objects, its fine The structure of the obturator is mainly used for building wall, roof insulation, composite board insulation, cold storage, air conditioning, vehicle, ship insulation, floor heating, widely

Send your message to us

Most Popular 2024 XPS Boards - Extruded Polystyrene

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords