XPS Extruded Polystyrene Board - Hot Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Type: | XPS Boards | Place of Origin: | Brand Name: | ||

| Model Number: | XPS.S-JSB | compressive strength: | min.300Kpa | thermal conductivity: | 0.029-0.036W/M.K |

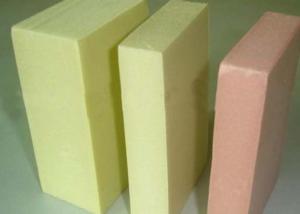

| material: | xps/eps, synthetic mortar | XPS color: | pink, blue, green |

Packaging & Delivery

| Packaging Detail: | 6mm: 20pcs/carton 10-20mm: 10pcs/carton 30-80mm:5pcs/carton |

| Delivery Detail: | WITHIN 25 DAYS AFTER RECEIPT OF THE DEPOSIT |

Specifications

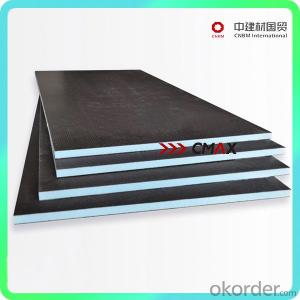

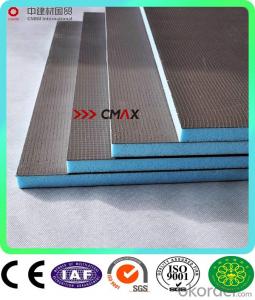

1.cement&glass+XPS+cement&glass mesh

2.size:1200-2500 L*600-1200 W *6-80mm T

3.CE approved

4.waterproof

5.light,easy install

Insulated Fiberglass tile backer boards are made from extruded polystyrene and finished both sides with a synthetic mortar reinforced with a glass fibre mesh. It is ideal for wet-zone and damp zone in a bathroom, washroom and shower area.

Characteristics:

1. Moisture and rot proof

It is ideal for bathrooms, showers and wetrooms, suitable for exteiror use.

2.Exceptional Stability

Eliminates the common cause of tile failure associated with mdf, chipboard, plywood, plaster and plasterboard.

3.High thermal insulation

Helps reduce heat loss. Recommended and suitable for use with all types of electrical underfloor heating.

4.Light weight and workable

Easier and faster to work with than all other type of building board.

5. Replace wet finishes

Can be used in place of floor screeds and rendered/plastered all finishes. Fast-tracks tiling and save costs.

Boards open up a whole new range partitions of any shape and design in minutes. This eliminates expensive labour costs and provides the ultimated substrate ready for both tile fixing or render finishes. It is easy for a person to do single handed as the boards are lightweight and very easy to cut with a saw or knife. Shield Waterproof Insulation board makes it easy to create a fully waterproof wetroom, covering the walls, floors and shower area.

XPS.S-JSB Sizes

Item No. | Length (mm) | Width (mm) | Thickness (mm) | Weight per sheet (kg) |

XET-J01 | 1200 | 600 | 6 | 2.0 |

XET-J02 | 1200 | 600 | 10 | 2.2 |

XET-J03 | 1200 | 600 | 12 | 2.3 |

XET-J04 | 1200 | 600 | 20 | 2.5 |

XET-J05 | 1200 | 600 | 30 | 2.7 |

XET-J06 | 1200 | 600 | 40 | 3.0 |

XET-J07 | 1200 | 600 | 50 | 3.3 |

XET-J08 | 1200 | 600 | 60 | 3.6 |

XET-J09 | 2500 | 600 | 10 | 4.6 |

XET-J10 | 2500 | 600 | 12 | 4.8 |

XET-J11 | 2500 | 600 | 20 | 5.2 |

XET-J12 | 2500 | 600 | 30 | 5.6 |

XET-J13 | 2500 | 600 | 40 | 6.3 |

XET-J14 | 2500 | 600 | 50 | 6.9 |

XET-J15 | 2500 | 600 | 60 | 7.5 |

We also can provide customized dimensions on request.

XPS.S-JSB Technical Data

Thermal conductivity, 90 days, 10°C | GB/T10294 (EN13164) | 0.030-0.036W/(M.K) |

Compressive strength at deformation of 10% | GB/T8813 (EN826) | Minimum of 300Kpa |

Bond Strength | N/A | 0.3N/mm2 |

Maximum tile loading weight | N/A | 60kg/M2 |

Bending Stiffness (20mm) | ASTM C203 | 2.00Mpa |

Moisture permeability | GB/T2406 (DIN EN 12086) | 3.2m |

Dimensional Stability | N/A | ≤1.0 |

Working temperature | N/A | -50°C-80°C |

Other Data of XPS.S-JSB

Insulation Board Thickness (mm) | XPS thickness (mm) | R-value (m.k/w) | Heat transmission coefficient at 10°C (W/ M2XK) | Heat transmission coefficient at 10°C (W/ M2XK) |

6 | 5 | 0.16 | 3.19 | 3.54 |

10 | 9 | 0.28 | 2.33 | 2.52 |

12 | 11 | 0.36 | 2.69 | 2.06 |

20 | 19 | 0.59 | 1.40 | 1.46 |

30 | 29 | 0.91 | 0.99 | 1.03 |

40 | 39 | 1.22 | 0.75 | 0.80 |

50 | 49 | 1.53 | 0.62 | 0.65 |

60 | 59 | 1.84 | 0.53 | 0.54 |

80 | 79 | 2.93 | 0.48 | 0.36 |

- Q: 25 thick extruded polystyrene plastic insulation board how many kilograms per cubic meter

- Sandwich board is made of color coated board, stainless steel and other materials as the surface of the composite board, because of its unique dust, anti-static, anti-bacterial effect, is widely used in electronics, pharmaceuticals, food, biological, aerospace, precision Equipment manufacturing and scientific research on the indoor environment demanding clean engineering areas

- Q: How is the flame and combustible defined by the naked eye? I burn the B1 level and B2 level XPS board is different? Question added: detection time is longer, can quickly and intuitively identified? More

- Mainly for insulation to reduce heat loss. So use a good insulation material insulation. Hope it helps you.

- Q: Roofing the top of the extruded polystyrene insulation board generally how much weight ah?

- The bar spacing is called 'step distance', 1.2 ~ 1..1.8m, no minimum spacing, maximum 1.8m. Pole spacing 1..1..1.55m, no minimum spacing, maximum 1.55m. See JGJ130 Haifa Fenzhuang Curcuma Gufeng Koufukai -2011 "Construction Construction Fastener Steel Scaffolding Safety Technical Specification" 'Structural Requirements'.

- Q: Why extruded board (XPS board) is the best insulation board material

- Should belong to the template and support system. Full scaffolding is generally used for single-storey building, hall and other high-rise, large building between the top of the building decoration. By the pole, cross bar, bracing, scissors and other components.

- Q: I set up in October 2008, the production of XPS board - that is, with the extinction of polystyrene foam plastic plate, is an energy-saving environmental protection materials. Consult experts: I can enjoy the relevant tax incentives?

- the inner wall insulation, as the name suggests is the wall inside the house Hu Dangan citrus spinning song dead building, the use of spraying, bonding, pouring, etc

- Q: Sound insulation and polystyrene insulation board which sound insulation better?

- Can be considered ultra-fine inorganic fiber spraying, this insulation material is sprayed up, not limited by the shape of the building, the speed is still fast

- Q: Steel plant wall plug color steel tile, the glass glass inside the glass, hanging in color steel, how construction? How is the cost associated with a single sandwich panel?

- Flexible waterproof casing for Shanghai Geng high international 薨 uan arm for the seismic fortification requirements of the area, the pipeline through the walls to withstand vibration and pipe telescopic deformation, or a strict waterproof requirements of the building (building) buildings

- Q: Extruded Polystyrene Board, Polystyrene Foam Board and Expanded Polystyrene Board

- Market price, no quota. According to the different brands, the price is different! I hope useful to you!

- Q: Polystyrene foam hard insulation board will not be harmful to the human body, right?

- Online under ah ~ ~! A few days ago I have a ~ ~!

- Q: The traditional ceramic insulation board, the existing thermal insulation coating in addition to the process and the construction period there are similarities and differences there are differences? Which energy-saving building is better?

- Single-row fastener type steel pipe scaffold for decoration works in the construction of small horizontal bar spacing should be the number of mm.........................................................

Send your message to us

XPS Extruded Polystyrene Board - Hot Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords