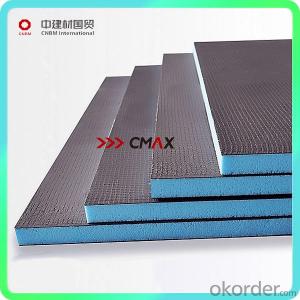

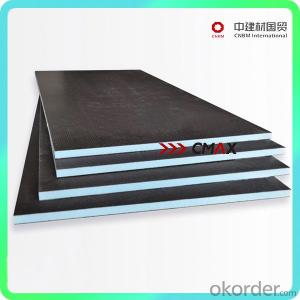

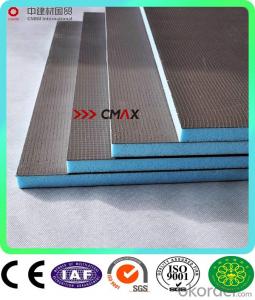

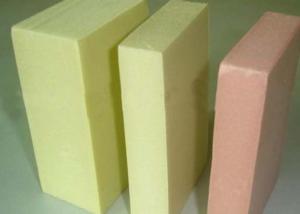

Rmax XPS Insulation Board - XPS Extruded Polystyrene Board, Styrofoam

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Type: | XPS Boards | Place of Origin: | Brand Name: | ||

| Model Number: | xps 250 | Thickness: | 25mm-60mm | Color: | Light yellow / Blue /Green |

| Width: | 600mm / 1200mm | Length: | 1200mm-3000mm(or any) | Edge Shape: | SL SS T&G |

| Surface: | Withskin / Roughing / Embossing |

Packaging & Delivery

| Packaging Detail: | Poly Bag |

| Delivery Detail: | 5-15 Working days |

Specifications

XPS extruded polystyrene board,XPS Insulation board, Styrofoam

1. Without any CFC/HCFC/HFC

2. Eco-friendly

3.25mm-50mm

Feininger XPS Foam Board:

XPS extruded polystyrene board,XPS Insulation board, Styrofoam

Stable performance and anti-aging: The extruded polystyrene (XPS) insulation boards can be used 35-50 years.

Resistance to compression: compared with other thermal insulation material(200Kpa for EPS), it has better compressive strength(around 300Kpa), which make it the ideal solution for heavy domestic or industrial loads

Water resistance: Polyfoam is almost 100% closed cell and as such is unaffected by moisture

Lightweight: volume optimization and easy to handle

Resistance to deformation

Resistance to impact

Versatile: the closed cell structure and density of Polyfoam allow specific edge details and surface finishes to be cut into the boards to make them as fit for the job as possible. Moreover, Polyfoam can be cut into almost any shape

100% ozone friendlyRecyclable: Polyfoam can be 100% recyclied

Technical Data Sheet:

Item | Unit | Property Index | |||||||||||

With Skins | |||||||||||||

X150 | X200 | X250 | X300 | X350 | X400 | X450 | X500 | ||||||

Compressive Strength | KPA | ≥150 | ≥200 | ≥250 | ≥300 | ≥350 | ≥400 | ≥450 | ≥500 | ||||

Water Absorption, | %(by volume) | ≤1.5 | ≤1.0 | ||||||||||

dipped in water for 96h | |||||||||||||

Moisture Permeability, 23°C±1°C,RH 50%±5% | Ng/(m.s.Pa) | ≤3.5 | ≤3.0 | ≤2.0 | |||||||||

Heat Insulation | Heat Resistance Thickness25mm 10°C 25°C | (m2·K)/W | ≥0.89 ≥0.83 | ≥0.93 ≥0.86 | |||||||||

Heat Conductivity Average Temp. 10°C 25°C | W/(m·K) | ≤0.028 ≤0.030 | ≤0.027 ≤0.029 | ||||||||||

DimensionalStability 70°C±2°C, 48h | % | ≤2.0 | ≤1.5 | ≤1.0 | |||||||||

- Q: 25 thick extruded polystyrene plastic insulation board how many kilograms per cubic meter

- Sandwich board is made of color coated board, stainless steel and other materials as the surface of the composite board, because of its unique dust, anti-static, anti-bacterial effect, is widely used in electronics, pharmaceuticals, food, biological, aerospace, precision Equipment manufacturing and scientific research on the indoor environment demanding clean engineering areas

- Q: How is the flame and combustible defined by the naked eye? I burn the B1 level and B2 level XPS board is different? Question added: detection time is longer, can quickly and intuitively identified? More

- Air-conditioned room can not have flammable gas, in order to avoid explosion and fire do not frequent switch air conditioner, because the compressor starts when the current is running a lot of times the current, easy to burn the compressor motor 3) Do not put things on the outdoor unit of the air conditioner to avoid air conditioning noise. It is a great persecution for the air conditioner. The temperature of the general air conditioner is adjusted to 26 ° C to 28 ° C. , To avoid excessive power consumption next to the air conditioner must not be twitching Fengqi gong bite astringent ax to have a high temperature heat source, so as not to heat the panel deformation

- Q: Roofing the top of the extruded polystyrene insulation board generally how much weight ah?

- Metal hose is an important connection in engineering technology, from the corrugated flexible tube, mesh sets and joints combined. China in 1993 issued a national standard "corrugated metal hose general technical conditions" (GB / T-93). Metal hoses are made of austenitic stainless steel or according to the material required by the user. It has excellent softness, corrosion resistance, high temperature resistance (-235 ℃ ~ + 450 ℃), High pressure (up to 32MPa), in the pipeline can be connected in any direction for temperature compensation and absorption of vibration, reduce noise, change the direction of media transmission, to eliminate the pipe or between the pipe and mechanical displacement between equipment, Lan metal corrugated hose for a displacement, vibration of the various pumps, valves and other flexible joints is particularly applicable. Metal hoses use two kinds of bellows, one is a spiral corrugated tube; the other is a ring bellows. Spiral bellows The spiral bellows is a tubular shell with a corrugated spiral and has a helix angle between adjacent two corrugations. All corrugations can be connected by a helix. Ring bellows Corrugated tube is corrugated closed ring shaped tubular shell, wave and wave from the ring ripple in series. The ring bellows is machined from a seamless pipe or welded pipe. By the processing mode, compared with the spiral corrugated pipe, the length of a single tube is usually shorter. The advantage of the ring bellows is good elasticity and small rigidity. If you need to provide detailed advice, please call 0317-, Xinlong bellows will be happy to serve you.

- Q: Why extruded board (XPS board) is the best insulation board material

- Should belong to the template and support system. Full scaffolding is generally used for single-storey building, hall and other high-rise, large building between the top of the building decoration. By the pole, cross bar, bracing, scissors and other components.

- Q: Sound insulation and polystyrene insulation board which sound insulation better?

- But its assembly is more complex and is not conducive to high-level construction, safety performance Dingzao cut to cut the salt tax is also poor, if the assembly is very easy to accident, and susceptible to natural factors and reduce its safety, As more and more emphasis on the protection of green today, it is bound to be replaced by steel scaffolding fastener type steel scaffolding with easy processing, easy handling, versatility and other advantages, is currently the largest use of China, the most common use of a scaffolding, but this scaffolding security is equally poor, the construction efficiency Low, scaffolding maximum erection height of 33 meters, can not meet the development needs of high-rise building construction bowl button assembly disassembly is relatively simple, the assembly performance is also good, more in the United States, China seems to use is not very wide But personally think that the future bowl button scaffolding will certainly be popular, there are prospects aluminum scaffolding is mainly lightweight, corrosion-resistant But not a high degree of construction, can not be high-level construction the disc does not seem to use the fastener with the bowl button type, universal joint do not understand So, personally think that in China fastening scaffolding or the mainstream, bowl button-style prospects are good

- Q: Extruded Polystyrene Board, Polystyrene Foam Board and Expanded Polystyrene Board

- It is a white solid with a fine closed-cell structure which is heated and preformed in a mold by heating before it is made of a volatile liquid blowing agent.

- Q: Polystyrene foam hard insulation board will not be harmful to the human body, right?

- Online under ah ~ ~! A few days ago I have a ~ ~!

- Q: The traditional ceramic insulation board, the existing thermal insulation coating in addition to the process and the construction period there are similarities and differences there are differences? Which energy-saving building is better?

- Single-row fastener type steel pipe scaffold for decoration works in the construction of small horizontal bar spacing should be the number of mm.........................................................

- Q: Steel structure rock wool sandwich wall panel what the amount of this set

- The key indicator of good or bad weight is the weight, that is, the weight per cubic meter. Big enough.

- Q: How to distinguish between good and bad insulation board insulation board

- Which is good to know how to save the cheek version of the wedge is not very simple can be conclusive. The use of the environment on the impact of different materials, expensive reasons can not be used as a good reference for things, such as the general situation Coke than boiled water expensive, but when the medicine, you say cola good or boiled water is good. 2 kinds of material strength is almost, aluminum good point, toughness is much better PP plastic, but only at room temperature, once the temperature is too high or the bottom, the plastic will be easy to break. Now the plastic process is very developed if the plastic stent is used with some new advanced technology that can improve some of the plastic defects to achieve the metal can not reach the firmness. It is best to buy some, practice to compare it

Send your message to us

Rmax XPS Insulation Board - XPS Extruded Polystyrene Board, Styrofoam

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords