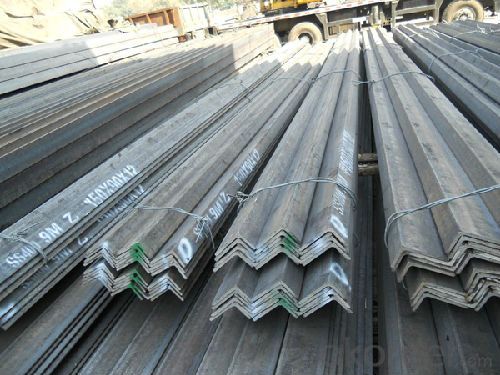

Mild Low Carbon Steel Equal Angles for Wareouses GB, JIS Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Mild Low Carbon Steel Equal Angles for Wareouses GB, JIS Standard at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Mild Low Carbon Steel Equal Angles for Wareouses GB, JIS Standard are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Mild Low Carbon Steel Equal Angles for Wareouses GB, JIS Standard are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

1.High quality

2.Suitable price

3.Factory provide directly.

4.Size: 2#-20# /4.5#-20#

Standard:AISI,ASTM,GB,JIS

Dimensions:

1. Equal Angle: 25*25*3mm- 200*200*14/16/18/20mm

2.Unequal Angle: 45*30*4mm-200*125*12/14/16/18mm

Grade:Q235-Q345 Series

Angle steel: equal/Unequal angle bar

| Dimension (mm) | Weight(kg/m) | Dimension (mm) | Weight(kg/m) |

| 20*3 | 0.89 | 80*10 | 11.87 |

| 20*4 | 1.15 | 90*6 | 8.35 |

| 25*3 | 1.12 | 90*7 | 9.66 |

| 25*4 | 1.46 | 90*8 | 10.95 |

| 30*3 | 1.37 | 90*10 | 13.48 |

| 30*4 | 1.79 | 90*12 | 15.94 |

| 36*3 | 1.66 | 100*6 | 9.37 |

| 36*4 | 2.16 | 100*7 | 10.83 |

| 36*5 | 2.65 | 100*8 | 12.28 |

| 40*3 | 1.85 | 100*10 | 15.12 |

| 40*4 | 2.42 | 100*12 | 17.9 |

| 40*5 | 2.98 | 100*14 | 20.61 |

| 45*3 | 2.09 | 100*16 | 23.26 |

| 45*4 | 2.74 | 110*7 | 11.93 |

| 45*5 | 3.37 | 110*8 | 13.53 |

| 45*6 | 3.99 | 110*10 | 16.69 |

| 50*3 | 2.33 | 110*12 | 19.78 |

| 50*4 | 3.06 | 110*14 | 22.81 |

| 50*5 | 3.77 | 125*8 | 15.5 |

| 50*6 | 4.46 | 125*10 | 19.13 |

| 56*3 | 2.62 | 125*12 | 22.7 |

| 56*4 | 3.45 | 125*14 | 26.19 |

| 56*5 | 4.25 | 140*10 | 21.49 |

| 56*8 | 6.57 | 140*12 | 25.52 |

| 63*4 | 3.91 | 140*14 | 29.49 |

| 63*5 | 4.82 | 140*16 | 33.39 |

| 63*6 | 5.72 | 160*10 | 24.73 |

| 63*8 | 7.47 | 160*12 | 29.39 |

| 63*10 | 9.15 | 160*14 | 33.99 |

| 70*4 | 4.37 | 160*16 | 38.52 |

| 70*5 | 5.4 | 180*12 | 33.16 |

| 70*6 | 6.41 | 180*14 | 38.38 |

| 70*7 | 7.4 | 180*16 | 43.54 |

| 70*8 | 8.37 | 180*18 | 48.63 |

| 75*5 | 5.82 | 200*14 | 42.89 |

| 75*6 | 6.91 | 200*16 | 48.68 |

| 75*7 | 7.98 | 200*18 | 54.4 |

| 75*8 | 9.03 | 200*20 | 60.06 |

| 75*10 | 11.09 | 200*24 | 71.17 |

| 80*5 | 6.21 | ||

| 80*6 | 7.38 | ||

| 80*7 | 8.53 | ||

| 80*8 | 9.66 |

| Dimension (mm) | Weight(kg/m) | Dimension (mm) | Weight(kg/m) |

| 25*16*3 | 0.91 | 100*63*6 | 7.55 |

| 25*16*4 | 1.18 | 100*63*7 | 8.72 |

| 32*20*3 | 1.17 | 100*63*8 | 9.88 |

| 32*20*4 | 1.52 | 100*63*10 | 12.1 |

| 40*25*3 | 1.48 | 100*80*6 | 8.35 |

| 40*25*4 | 1.94 | 100*80*7 | 9.66 |

| 45*28*4 | 1.69 | 100*80*8 | 10.9 |

| 45*28*5 | 2.2 | 100*80*10 | 13.5 |

| 50*32*3 | 1.91 | 110*70*6 | 8.35 |

| 50*32*4 | 2.49 | 110*70*7 | 9.66 |

| 56*36*3 | 2.15 | 110*70*8 | 10.9 |

| 56*36*4 | 2.82 | 110*70*10 | 13.5 |

| 56*36*5 | 3.47 | 125*80*7 | 11.1 |

| 63*40*4 | 3.19 | 125*80*8 | 12.6 |

| 63*40*5 | 3.92 | 125*80*10 | 15.5 |

| 63*40*6 | 4.64 | 125*80*12 | 18.3 |

| 63*40*7 | 10 | 140*90*8 | 14.2 |

| 70*45*4 | 3.57 | 140*90*10 | 17.5 |

| 70*45*5 | 4.4 | 140*90*12 | 20.7 |

| 70*45*6 | 5.22 | 140*90*14 | 23.9 |

| 70*45*7 | 6.01 | 160*100*10 | 19.9 |

| 75*50*5 | 4.81 | 160*100*12 | 23.6 |

| 75*50*6 | 5.7 | 160*100*14 | 27.2 |

| 75*50*8 | 7.43 | 160*100*16 | 30.8 |

| 75*50*10 | 9.1 | 180*110*10 | 22.3 |

| 80*50*5 | 5 | 180*110*12 | 26.5 |

| 80*50*6 | 5.93 | 180*110*14 | 30.6 |

| 80*50*7 | 6.85 | 180*110*16 | 34.6 |

| 80*50*8 | 7.75 | 200*125*12 | 29.8 |

| 90*56*5 | 5.66 | 200*125*14 | 34.4 |

| 90*56*6 | 6.72 | 200*125*16 | 39 |

| 90*56*7 | 7.76 | 200*125*18 | 43.6 |

| 90*56*8 | 8.78 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q: What is the difference between the main keel and the angle steel and the channel steel?

- Channel steel is a kind of carbon structural steel used for construction and machinery. It is a complex section steel. Its cross section has a groove shape. Channel steel is mainly used in building structure, curtain wall engineering, mechanical equipment and vehicle manufacturing, etc.. In use, it requires better welding, riveting performance and comprehensive mechanical properties. The raw material steel billet for channel steel is carbon or low alloy steel billets with a carbon content of not more than 0.25%. The finished channel steel is delivered by hot forming, normalizing or hot rolling. The specifications are expressed in millimeters of height (H) * leg width (b) * waist thickness (d), such as 100*48*5.3, which means waist height is 100 mm, leg width is 48 mm, waist thickness is 5.3 mm channel, or 10# channel steel. The same height of the channel, if there are several different leg width and waist thickness, also need to add a, B, C on the right side of the model to distinguish, such as 25#a, 25#b, 25#c and so on.

- Q: Can steel angles be used as supports for overhead doors or garage doors?

- Indeed, overhead doors or garage doors can rely on steel angles as their supports. Due to their impressive strength and durability, steel angles are frequently employed in construction. They offer superb support and stability for hefty doors, making them an ideal selection for overhead or garage doors. By securely fastening the angles to the walls or framework, a sturdy foundation is provided for the doors to hang on and function seamlessly. Moreover, steel angles can be tailored to fit the precise dimensions and weight prerequisites of the doors, guaranteeing adequate support and functionality.

- Q: Can steel angles be used in modular or prefabricated construction?

- Yes, steel angles can be used in modular or prefabricated construction. Steel angles are commonly used as structural components in construction due to their strength and versatility. They can be easily fabricated and integrated into modular or prefabricated building systems, allowing for efficient and cost-effective construction processes. Steel angles can be used to provide structural support, reinforce connections, and create framing systems in modular or prefabricated buildings. Additionally, their ability to be customized and adapted to various design requirements makes them suitable for a wide range of building applications in the modular or prefabricated construction industry.

- Q: What are the limitations of using steel angles?

- There are several limitations associated with the use of steel angles in various applications. Firstly, steel angles have a limited load-bearing capacity. The weight and pressure that can be safely supported by a steel angle are determined by its size, shape, and material composition. If the load exceeds the weight-bearing capacity of the angle, it can lead to structural failure or deformation. Secondly, steel angles are susceptible to corrosion. They are typically made of carbon steel, which can rust over time when exposed to moisture or corrosive environments. This corrosion weakens the structural integrity of the angle, reducing its lifespan and potentially compromising the overall stability of the structure it supports. Additionally, steel angles may have limitations in terms of their flexibility and versatility. Due to their fixed shape and size, they may not be suitable for applications that require intricate or complex designs. In such cases, alternative materials or fabrication methods may be more appropriate. Another limitation of steel angles is their limited resistance to fire. Steel, including steel angles, loses its strength and structural integrity at high temperatures. In the event of a fire, steel angles may not be able to withstand the heat and can deform or collapse, jeopardizing the safety of the structure and its occupants. Lastly, steel angles can be challenging to work with during installation or modification. Their rigid nature may require specialized tools, equipment, or expertise for cutting, drilling, or welding. This can add to the overall cost and time required for construction or renovation projects. Despite these limitations, steel angles remain widely used in various industries due to their affordability, durability, and versatility within their design limits. However, it is essential to consider these limitations and evaluate the specific requirements of each application to determine if steel angles are the most suitable choice.

- Q: What are the advantages of using steel angles over other materials?

- There are several advantages of using steel angles over other materials. Firstly, steel angles offer exceptional strength and durability, making them suitable for a wide range of structural applications. They can withstand heavy loads and provide reliable support, ensuring structural integrity. Additionally, steel angles are versatile as they can be easily customized and fabricated to meet specific design requirements. They are also cost-effective in terms of long-term maintenance and repair, as steel is highly resistant to corrosion and requires minimal upkeep. Lastly, steel angles offer excellent fire resistance, making them a safe choice for construction projects.

- Q: Can steel angles be used for shelving?

- Yes, steel angles can be used for shelving. Steel angles are commonly used in shelving systems due to their durability and strength. They provide sturdy support for shelves and can withstand heavy loads. Additionally, steel angles are versatile and can be easily customized to fit different shelving configurations. They are often used in industrial settings, warehouses, garages, and even in residential applications where a strong and reliable shelving solution is desired.

- Q: Can steel angles be used for machine frames?

- Yes, steel angles can be used for machine frames. Steel angles are commonly used in construction and can provide structural support, stability, and durability to machine frames. They offer a strong and rigid framework that can withstand heavy loads and vibrations, making them suitable for various types of machinery.

- Q: Can steel angles be used in conveyor systems?

- Yes, steel angles can be used in conveyor systems. Steel angles are commonly used as structural support and reinforcement in conveyor systems due to their strength, durability, and versatility. They can provide stability and rigidity to the conveyor structure, ensuring smooth and efficient material handling.

- Q: Can steel angles be used for shelving units?

- Absolutely! Shelving units can indeed utilize steel angles. These angles are widely employed in construction and industrial settings owing to their impressive robustness and endurance. They offer exceptional structural reinforcement and can effortlessly bear substantial loads, rendering them perfect for shelving units that necessitate the support of considerable weight. Moreover, steel angles are incredibly adaptable and can be effortlessly tailored to suit diverse shelving designs and setups. Whether it be for domestic, corporate, or commercial purposes, steel angles are a dependable option for crafting resilient and enduring shelving units.

- Q: Are steel angles corrosion resistant?

- Steel angles, unless specially designed and treated, are generally prone to corrosion. They are typically made from carbon steel, which can corrode when exposed to moisture, oxygen, and other corrosive substances. Nevertheless, stainless steel angles, enhanced with chromium and other alloying elements, offer greater resistance to corrosion. These stainless steel angles are commonly employed in corrosive environments like marine or industrial settings. To evaluate the corrosion resistance of a steel angle, one must carefully consider its specific type and grade.

Send your message to us

Mild Low Carbon Steel Equal Angles for Wareouses GB, JIS Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords