Mica Parts Used for Food Service Equipment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

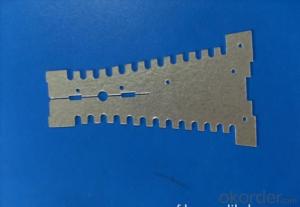

1. Introductions:

Mica is a rigid substrate able to withstand very high temperatures and are suited for applications up to 500°F (260°C). Mica heating elements offer several distinct advantages over other flexible heater technologies, including extremely low leakage, lower material costs, and higher operating temperatures. Our mica heating element is made by detail order requirments.

2. Applications:

Typical applications of mica heating elements are air heaters, enclosure systems, food service equipment, process and packaging equipment.

3. Main features of Mica Parts:

Mica heating elements offer several distinct advantages over other flexible heater technologies, including extremely low leakage, lower material costs, and higher operating temperatures. Our mica heating element is made by detail order requirments.

4. Technical Parameters:

MICA SHEET -----Technical data | ||||||||

ITEM | UNIT | RM | RP | RM-T | RP-T | FM | FP | |

Hardness |

| Rigid | Rigid | Rigid | Rigid | Flexible | Flexible | |

Mica paper |

| Muscovite | Phlogopite | Muscovite | Phlogopite | Muscovite | Phlogopite | |

Thickness | mm | 0.1-2.0 | 0.1-2.0 | 3.0-50 | 3.0-50 | 0.1-2.0 | 0.1-2.0 | |

Mica content | % | ≥90 | ≥90 | >88 | >88 | ≥90 | ≥90 | |

Bond Content | % | <10< span=""> | <10< span=""> | <12< span=""> | <12< span=""> | <10< span=""> | <10< span=""> | |

Density | g/m 3 | 1.6~2.45 | 1.6~2.45 | 2.1~2.4 | 2.1~2.4 | 1.6~2.45 | 1.6~2.45 | |

Heat | Continuous | ℃ | 500 | 700 | 500 | 700 | 500 | 700 |

Peak | ℃ | 700 | 900 | 700 | 900 | 700 | 900 | |

Heat loss at 500℃ | % | <1< span=""> | <1< span=""> | <1< span=""> | <2< span=""> | <1< span=""> | <1< span=""> | |

Heat loss at 700℃ | % | <2< span=""> | <2< span=""> | <1< span=""> | <2< span=""> | <2< span=""> | <2< span=""> | |

Flexural strength | Mpa | >160 | >140 | — | — | <1< span=""> | <1< span=""> | |

Water absorption 24h/23°C | % | <1< span=""> | <1< span=""> | <1< span=""> | <2< span=""> | — | — | |

Dielectric strength | KV/mm | >20 | >20 | >15 | >15 | >15 | >15 | |

Volume | 23℃ | ΩNaN | >1017 | >1017 | >1017 | >1017 | — | — |

500℃ | ΩNaN | >1012 | >1012 | >1012 | >1012 | — | — | |

Smoking Test | s | <4< span=""> | <4< span=""> | — | — | — | — | |

FAQ

We have organized several common questions for our clients,may help you sincerely:

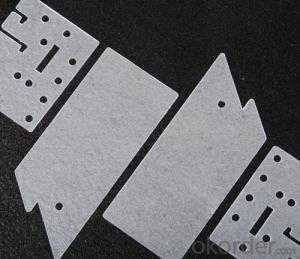

--------What is the use of mica parts?

Mica laminate and washers made of our own high quality mica plates are used for home appliances, electro-magnets, micro-sensitive control gear etc

---------Which type of mica parts we can produce?

1. Rigid mica parts or Flexible mica parts

2. Muscovite mica parts or phlogopite mica parts

3. Thin mica parts or thick mica parts

4. All the special sized mica parts need drawing.

----------what advantages of mica parts?

1. Good high voltage insulation materials

2. Do not easily break up

3. Easily produce special size

- Q: What is the electrical performance of insulating materials

- The electrical insulating material is a material that is electrically insulated from the device and has a certain mechanical strength, typically having a resistivity of 106 to 1019.cm. Their function in electrical technology is as follows: 1 Insulate the conductor from the other parts; 2 Separate the conductors of different potentials 3 Provide the conditions for the energy storage of the capacitor 4 Improve the potential gradient in the high voltage electric field.

- Q: What is the 8 ° C rule for insulating materials?

- Insulation material 8 ℃ rules: Insulation material used in the temperature exceeds the limit temperature, the insulation material will quickly deteriorate, the service life will be greatly reduced.

- Q: Brass is not an insulating material?

- Brass is not insulating material. On the contrary is the brass is conductive material. Brass texture hard, can not bend. No copper flexibility is good, so brass can only do a fixed copper conductive use.

- Q: What kind of insulation is the insulating

- Insulation is the core technology of aluminum substrate. Currently on the market most of the aluminum substrate insulation layer using epoxy resin, the advantages of this type of insulation is: good adhesion; drawback is: thermal resistance, dielectric strength is limited, it is difficult to meet the safety requirements. Such aluminum substrates are only suitable for low power density applications. High-end aluminum substrate insulation layer is generally composed of high thermal conductivity and high insulation ceramic powder filled with special polymer composition.

- Q: What type of enameled wire and insulation material is used for the compressor

- Motor insulation class The insulation class is divided according to the permissible limit temperature of the insulation material used for the motor. There are Y, A, E, B, F, H, C and several other levels, the allowable limit temperature at all levels as shown in the table below. The so-called permissible limit temperature refers to the permissible maximum operating temperature of the motor insulation material, which reflects the heat resistance of the insulating material. Insulation material is divided into Y grade, A grade, grade E, grade B, grade F, grade H, grade C, permissible temperature (℃) 90,105,120,130,155,180, 180 ℃ or higher.

- Q: Insulation material and the definition of the role of the best professional insulation materials website for my reference

- Electrical strength is the breakdown of the voltage between the voltage and the two electrodes subjected to the applied voltage under the specified conditions, that is, the breakdown voltage per unit thickness. For insulating materials, the general breakdown voltage, electrical strength of the value of the higher the better. 4, tensile strength: in the tensile test, the sample to withstand the maximum tensile stress. It is the most widely used and tested test of the mechanical properties of insulating materials. 5, Flammability: refers to the insulation material in contact with the flame to resist combustion or leave the flame to prevent the ability to continue to burn. With the increasing use of insulating materials, its flammability requirements are more important, people through various means to improve and improve the insulation

- Q: Who knows what are the ability of 1300 degrees above the high temperature, insulation materials?

- Heat-resistant polymers can be used as high temperature resistant film insulation materials, high temperature resistant fibers, high temperature resistant coatings, high temperature adhesives. In accordance with the high temperature of the time, but also sub-instant high temperature materials and high temperature materials for a long time. The former in 1000 ~ 10000 ℃ can withstand a few seconds to a few minutes.

- Q: What is the main purpose of insulating materials?

- Insulation withstand voltage: the higher the voltage applied across the insulator, the greater the electric field force received by the material, the more prone to ionization collision, resulting in insulator breakdown. The lowest voltage breakdown of the insulator is called the breakdown of this insulator Voltage. 1 mm thick insulation material breakdown, the need to add the voltage kV is called insulation material insulation voltage strength, referred to as the dielectric strength

- Q: What are the commonly used insulating materials?

- Mainly used for motor, electrical winding insulation, switch the bottom plate and insulators, etc. Organic insulation materials are: shellac, resin, rubber, cotton yarn, paper, linen, rayon,

- Q: Wear-resistant, high temperature, insulation materials which

- Alumina - high temperature, corrosion resistance, wear resistance. Good electrical insulation 1600 ℃. For crucible, high temperature thermocouple casing, knives, mold and so on. Silicon nitride - has good high temperature strength, thermal expansion coefficient is small, high thermal conductivity, thermal shock resistance, the use of temperature as alumina, good electrical insulation. 1200 ℃ still have a high hardness. For mechanical seal ring, thermocouple casing, steam turbine blades and so on. Silicon carbide - high temperature strength, 1400 ℃ when the bending strength of (500 ~ 600) MPa. For the nozzle, furnace tubes, high temperature bearings, high temperature heat exchangers and so on.

Send your message to us

Mica Parts Used for Food Service Equipment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords