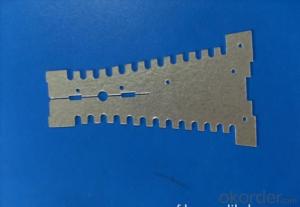

Mica Parts Used for Induction Furnace for Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Introductions:

Mica is a rigid substrate able to withstand very high temperatures and are suited for applications up to 500°F (260°C). Mica heating elements offer several distinct advantages over other flexible heater technologies, including extremely low leakage, lower material costs, and higher operating temperatures. Our mica heating element is made by detail order requirments.

2. Applications:

Typical applications of mica heating elements are air heaters, enclosure systems, food service equipment, process and packaging equipment.

3. Main features of Mica Parts:

Mica heating elements offer several distinct advantages over other flexible heater technologies, including extremely low leakage, lower material costs, and higher operating temperatures. Our mica heating element is made by detail order requirments.

4. Technical Parameters:

MICA SHEET -----Technical data | ||||||||

ITEM | UNIT | RM | RP | RM-T | RP-T | FM | FP | |

Hardness |

| Rigid | Rigid | Rigid | Rigid | Flexible | Flexible | |

Mica paper |

| Muscovite | Phlogopite | Muscovite | Phlogopite | Muscovite | Phlogopite | |

Thickness | mm | 0.1-2.0 | 0.1-2.0 | 3.0-50 | 3.0-50 | 0.1-2.0 | 0.1-2.0 | |

Mica content | % | ≥90 | ≥90 | >88 | >88 | ≥90 | ≥90 | |

Bond Content | % | <10< span=""> | <10< span=""> | <12< span=""> | <12< span=""> | <10< span=""> | <10< span=""> | |

Density | g/m 3 | 1.6~2.45 | 1.6~2.45 | 2.1~2.4 | 2.1~2.4 | 1.6~2.45 | 1.6~2.45 | |

Heat | Continuous | ℃ | 500 | 700 | 500 | 700 | 500 | 700 |

Peak | ℃ | 700 | 900 | 700 | 900 | 700 | 900 | |

Heat loss at 500℃ | % | <1< span=""> | <1< span=""> | <1< span=""> | <2< span=""> | <1< span=""> | <1< span=""> | |

Heat loss at 700℃ | % | <2< span=""> | <2< span=""> | <1< span=""> | <2< span=""> | <2< span=""> | <2< span=""> | |

Flexural strength | Mpa | >160 | >140 | — | — | <1< span=""> | <1< span=""> | |

Water absorption 24h/23°C | % | <1< span=""> | <1< span=""> | <1< span=""> | <2< span=""> | — | — | |

Dielectric strength | KV/mm | >20 | >20 | >15 | >15 | >15 | >15 | |

Volume | 23℃ | ΩNaN | >1017 | >1017 | >1017 | >1017 | — | — |

500℃ | ΩNaN | >1012 | >1012 | >1012 | >1012 | — | — | |

Smoking Test | s | <4< span=""> | <4< span=""> | — | — | — | — | |

FAQ

We have organized several common questions for our clients,may help you sincerely:

--------What is the use of mica parts?

Mica laminate and washers made of our own high quality mica plates are used for home appliances, electro-magnets, micro-sensitive control gear etc

---------Which type of mica parts we can produce?

1. Rigid mica parts or Flexible mica parts

2. Muscovite mica parts or phlogopite mica parts

3. Thin mica parts or thick mica parts

4. All the special sized mica parts need drawing.

----------what advantages of mica parts?

1. Good high voltage insulation materials

2. Do not easily break up

3. Easily produce special size

- Q:Who knows what are the ability of 1300 degrees above the high temperature, insulation materials?

- Heat-resistant polymers can be used as high temperature resistant film insulation materials, high temperature resistant fibers, high temperature resistant coatings, high temperature adhesives. In accordance with the high temperature of the time, but also sub-instant high temperature materials and high temperature materials for a long time. The former in 1000 ~ 10000 ℃ can withstand a few seconds to a few minutes.

- Q:What are the gas insulation materials?

- In addition to air, nitrogen, carbon dioxide and sulfur hexafluoride gas, there are other gases used for insulation. CCl2F2 (freon-12) was used as an insulating in certain high-energy physical devices. CCl2F2 breakdown strength and SF6 similar, but because of its high liquefaction temperature, and the spark will make CCl2F2 precipitation of carbon particles, therefore, has been replaced by SF6. In hydrogen-cooled generators, hydrogen is also used as insulation in addition to cooling media.

- Q:What insulating materials are used for high frequency transformers?

- Which is divided into solvent and solvent-free paint is divided into two major categories, mainly used for dipping motor, electrical coil and insulation parts to fill its gap and microporous, immersion paint can be cured in the surface of the formation of continuous formation Of the film, and the coil into a solid as a whole, in order to improve the insulation structure of the moisture, thermal conductivity, dielectric strength and mechanical strength of the performance.

- Q:What is the thermal aging and electrical aging of insulating materials?

- Insulation materials in electrical equipment during the operation, due to the long-term effects of various factors, there will be a series of irreversible physical and chemical changes, resulting in its electrical performance and mechanical properties decline, commonly known as aging. There are many factors that affect the aging of insulating materials. The main aging forms are environmental aging, heat aging and electrical aging.

- Q:What is the 8 ° C rule for insulating materials?

- Such as A-class insulation material limit working temperature of 105 ℃, when the ultimate operating temperature of 8 ℃, its life will be reduced by about half, which is 8 ℃ thermal deterioration rules.

- Q:There are a lot of online about this, but still do not understand. If the insulation resistance is high enough, hit the pressure should also be qualified ah. There is insulation test itself when the current flow is not large, because the rock table resistance is great. But hit the pressure, I do not know is not a direct high pressure drop in the test product above, there is no great resistance to interference?

- People also know that the insulation Megohmmeter is issued by the DC, and because of the relationship between the instrument resistance, the actual output current is very small, but for the withstand voltage test equipment, the internal AC transformer, the output voltage and current Of the capacity, if the equipment capacity is insufficient, the test object when the required voltage is not necessarily able to achieve, so the output current is still relatively large, which is resistant to voltage test is easy to breakdown the test object, and insulation Resistance value is very low case will not breakdown the reasons for the test object.

- Q:What are the commonly used insulating materials?

- Commonly used inorganic insulation materials are: mica, asbestos, marble, porcelain, glass, sulfur and so on, which can be divided into inorganic insulating materials, organic insulating materials and mixed insulating materials.

- Q:Brass is not an insulating material?

- Brass is a particularly good conductive material and is a good material for wearing heat

- Q:What is the main purpose of insulating materials?

- The role of insulating material is in the electrical equipment to separate the potential of the live part of the insulation, so the insulation material should first have a high insulation resistance and pressure strength, and to avoid leakage, breakdown and other accidents.

- Q:What kind of insulation is the insulating

- Now most of the aluminum substrate in the insulating layer or epoxy (I do this, do not mention my company name, so that I advertise). Epoxy can be modified, and then through the surface treatment of the thermal filler, in the cross-linked when the formation of a most conducive to the heat transfer structure, so as to achieve the purpose of high thermal conductivity.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mica Parts Used for Induction Furnace for Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products