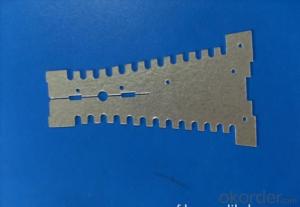

Mica Tube Used in Electric Home Appliances

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Introductions:

Mica tube is made of mica paper with highperformance organic silicon resin. After heating and pressing, the mica plate can be made into rigid or flexible insulating plates. The mica content is about 90% and the organic silicon resin content is 10%.

Mica is a rigid substrate able to withstand very high temperatures and are suited for applications up to 500°F (260°C). Mica heating elements offer several distinct advantages over other flexible heater technologies, including extremely low leakage, lower material costs, and higher operating temperatures. Our mica heating element is made by detail order requirments.

2. Applications:

Typical applications of mica heating elements are air heaters, enclosure systems, food service equipment, process and packaging equipment.

3. Main features of Mica Parts:

mica tubes are featured with high strength, good performance, less smoke, less odor etc. This series mica plates are used mainly in household appliances (toaster ovens, microwave ovens, warm air blowers, hair dryers, electric iron etc.), metallurgy (such as linefrequency furnaces, medium frequency furnaces, electric arc furnace, etc.), medical equipment and other industries, used as the heating support, lining plate and partition plate of the electric appliances described above.

4. Technical Parameters:

Tolerance for mica tube | ||

Internal diameter(mm) | Tolerance of ID(mm) | Tolerance of ID(mm) |

<10< span=""> | ±0.3 | ±0.4 |

10 ~ 20 | ±0.4 | ±0.5 |

21 ~ 50 | ±0.5 | ±0.7 |

51 ~ 100 | ±0.6 | ±1.0 |

101 ~ 200 | ±0.8 | ±1.2 |

201 ~ 300 | ±1.0 | ±1.5 |

Length: 10mm to 1000mm | ||

FAQ

We have organized several common questions for our clients,may help you sincerely:

--------What is the use of mica parts?

Mica laminate and washers made of our own high quality mica plates are used for home appliances, electro-magnets, micro-sensitive control gear etc

---------Which type of mica parts we can produce?

1. Rigid mica parts or Flexible mica parts

2. Muscovite mica parts or phlogopite mica parts

3. Thin mica parts or thick mica parts

4. All the special sized mica parts need drawing.

----------what advantages of mica parts?

1. Good high voltage insulation materials

2. Do not easily break up

3. Easily produce special size

- Q:What is the insulating material in the middle of the connecting wire?

- Looked for a long time to understand your problem, I can see with a relatively thin tube into the insulation, the insulation tube into a plug in the insulation of the skin. Or for the wire, without the foreskin of the wire is not safe

- Q:What insulating material is used for high voltage cables

- Etc., can withstand mechanical force and a certain tension. YJLV32 aluminum core XLPE insulated fine steel wire armored PVC sheathed power cable YJV33 copper core XLPE insulated fine steel wire armored PVC sheathed power cable YJLV33 aluminum core XLPE insulated steel tape armored PVC sheathed power cable

- Q:What is the thermal aging and electrical aging of insulating materials?

- Insulation materials in electrical equipment during the operation, due to the long-term effects of various factors, there will be a series of irreversible physical and chemical changes, resulting in its electrical performance and mechanical properties decline, commonly known as aging. There are many factors that affect the aging of insulating materials. The main aging forms are environmental aging, heat aging and electrical aging.

- Q:What insulating materials are used for transformers

- With the largest number of cardboard, as well as laminated wood, insulating paper, transformer oil, large oil-immersed transformers are mostly oil - paper insulation.

- Q:What is the DMD insulation material?

- DMD (Dacron / Mylar / Dacron) full name polyester film polyester fiber non-woven soft composite foil, is a two-layer polyester non-woven fabric in the middle of a layer of insulated polyester film composite made of three insulation materials.

- Q:What are the commonly used insulating materials?

- Commonly used inorganic insulation materials are: mica, asbestos, marble, porcelain, glass, sulfur and so on, which can be divided into inorganic insulating materials, organic insulating materials and mixed insulating materials.

- Q:What type of enameled wire and insulation material is used for the compressor

- Small and medium-sized closed, semi-enclosed refrigeration compressors are used for the specific enameled wire specifically (QF) series.

- Q:What insulating material is best `?

- Gas insulation material has a high ionization field strength and breakdown field strength, after the breakdown can quickly restore insulation performance, chemical stability, non-combustible, non-explosive, non-aging, non-corrosive, easy to discharge decomposition, and greater heat capacity , The thermal conductivity, and the flowability are all. The air is the most widely used gas insulating material, for example, between the overhead wires of the AC and DC transmission lines, and the overhead wires are insulated by air. The high voltage standard capacitors also use gas insulating media (SF6) .SF6 is also used in the manufacture of high-voltage circuit breakers, metal-enclosed combination of electrical appliances, gas-insulated transmission pipeline cables and gas-insulated transformers, etc., the use of high-pressure nitrogen or carbon dioxide.

- Q:Brass is not an insulating material?

- Of course not, brass is still relatively good conductor blanket, and also has good thermal conductivity

- Q:What kind of insulation is the insulating

- Ordinary heat conduction is made with fiberglass PP2. High thermal conductivity materials are made of thermally conductive

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mica Tube Used in Electric Home Appliances

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords