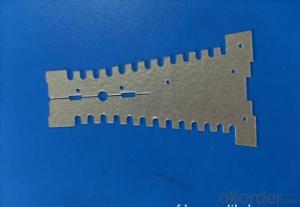

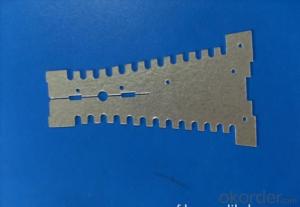

Mica Parts Used for Microwave Ovens Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Introductions:

Mica plate is made of mica paper with highperformance organic silicon resin. After heating and pressing, the mica plate can be made into rigid or flexible insulating plates. The mica content is about 90% and the organic silicon resin content is 10%.

Mica is a rigid substrate able to withstand very high temperatures and are suited for applications up to 500°F (260°C). Mica heating elements offer several distinct advantages over other flexible heater technologies, including extremely low leakage, lower material costs, and higher operating temperatures. Our mica heating element is made by detail order requirments.

2. Applications:

Typical applications of mica heating elements are air heaters, enclosure systems, food service equipment, process and packaging equipment.

3. Main features of Mica Parts:

Rigid mica plates are featured with high strength, good performance, less smoke, less odor etc.

This series mica plates are used mainly in household appliances (toaster ovens, microwave ovens, warm air blowers, hair dryers, electric iron etc.), metallurgy (such as line-frequency furnaces, medium frequency furnaces, electric arc furnace, etc.), medical equipment and other industries, used as the heating support, lining plate and partition plate of the electric appliances described above.

4. Technical Parameters:

MICA SHEET -----Technical data | ||||||||

ITEM | UNIT | RM | RP | RM-T | RP-T | FM | FP | |

Hardness |

| Rigid | Rigid | Rigid | Rigid | Flexible | Flexible | |

Mica paper |

| Muscovite | Phlogopite | Muscovite | Phlogopite | Muscovite | Phlogopite | |

Thickness | mm | 0.1-2.0 | 0.1-2.0 | 3.0-50 | 3.0-50 | 0.1-2.0 | 0.1-2.0 | |

Mica content | % | ≥90 | ≥90 | >88 | >88 | ≥90 | ≥90 | |

Bond Content | % | <10< span=""> | <10< span=""> | <12< span=""> | <12< span=""> | <10< span=""> | <10< span=""> | |

Density | g/m 3 | 1.6~2.45 | 1.6~2.45 | 2.1~2.4 | 2.1~2.4 | 1.6~2.45 | 1.6~2.45 | |

Heat | Continuous | ℃ | 500 | 700 | 500 | 700 | 500 | 700 |

Peak | ℃ | 700 | 900 | 700 | 900 | 700 | 900 | |

Heat loss at 500℃ | % | <1< span=""> | <1< span=""> | <1< span=""> | <2< span=""> | <1< span=""> | <1< span=""> | |

Heat loss at 700℃ | % | <2< span=""> | <2< span=""> | <1< span=""> | <2< span=""> | <2< span=""> | <2< span=""> | |

Flexural strength | Mpa | >160 | >140 | — | — | <1< span=""> | <1< span=""> | |

Water absorption 24h/23°C | % | <1< span=""> | <1< span=""> | <1< span=""> | <2< span=""> | — | — | |

Dielectric strength | KV/mm | >20 | >20 | >15 | >15 | >15 | >15 | |

Volume | 23℃ | ΩNaN | >1017 | >1017 | >1017 | >1017 | — | — |

500℃ | ΩNaN | >1012 | >1012 | >1012 | >1012 | — | — | |

Smoking Test | s | <4< span=""> | <4< span=""> | — | — | — | — | |

FAQ

We have organized several common questions for our clients,may help you sincerely:

--------What is the use of mica parts?

Mica laminate and washers made of our own high quality mica plates are used for home appliances, electro-magnets, micro-sensitive control gear etc

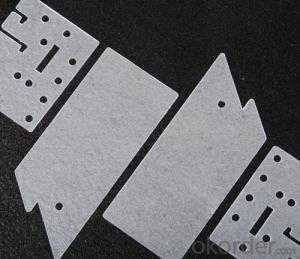

---------Which type of mica parts we can produce?

1. Rigid mica parts or Flexible mica parts

2. Muscovite mica parts or phlogopite mica parts

3. Thin mica parts or thick mica parts

4. All the special sized mica parts need drawing.

----------what advantages of mica parts?

1. Good high voltage insulation materials

2. Do not easily break up

3. Easily produce special size

- Q: What is the 8 ° C rule for insulating materials?

- Insulation material 8 ℃ rules: Insulation material used in the temperature exceeds the limit temperature, the insulation material will quickly deteriorate, the service life will be greatly reduced.

- Q: What kind of insulation is the insulating

- Now most of the aluminum substrate in the insulating layer or epoxy (I do this, do not mention my company name, so that I advertise). Epoxy can be modified, and then through the surface treatment of the thermal filler, in the cross-linked when the formation of a most conducive to the heat transfer structure, so as to achieve the purpose of high thermal conductivity.

- Q: Insulation material and the definition of the role of the best professional insulation materials website for my reference

- According to the national standard GB2900.5 provides the definition of insulating material is: "used to make the device in the electrical insulation of the material." That is, to prevent the current through the material.

- Q: What insulating materials are used for transformers

- Dry type transformers before the 1960s are mainly B-type insulation of the open-type dry-type transformers, product model for the SG type. When there is no foil coil, the low pressure for the majority of multi-root and around the layer or spiral coil, high pressure for the pie coil. Wire for the double glass envelope or single glass fiber package enamel enameled wire. The rest of the insulating material is mostly phenolic glass fiber materials. The impregnation process for the room temperature, atmospheric pressure with B-class insulation impregnated paint were high and low pressure coil impregnation and drying at the temperature (drying temperature does not exceed 130 ℃). Although this dry-type transformers than oil-immersed transformers in the fire performance has made great progress, but its moisture, anti-pollution performance is worrying. Is no longer produced. Nevertheless, its successful electrical, magnetic, thermal calculations and structural design have laid a good foundation for the new H-class insulated open-ended transformers that have evolved later.

- Q: Who knows what are the ability of 1300 degrees above the high temperature, insulation materials?

- Where the ablative material is also high temperature resistant material. For example, in the 300 ~ 600 ℃, in the air to maintain its mechanical strength, chemical resistance and so on.

- Q: What are the gas insulation materials?

- In addition to air, nitrogen, carbon dioxide and sulfur hexafluoride gas, there are other gases used for insulation. CCl2F2 (freon-12) was used as an insulating in certain high-energy physical devices. CCl2F2 breakdown strength and SF6 similar, but because of its high liquefaction temperature, and the spark will make CCl2F2 precipitation of carbon particles, therefore, has been replaced by SF6. In hydrogen-cooled generators, hydrogen is also used as insulation in addition to cooling media.

- Q: What are the commonly used insulating materials?

- Mostly used to make insulating varnishes, winding wires, etc. Insulation materials are made of the above two kinds of materials made of various molding insulation materials, used as electrical appliances of the base, shell and so on.

- Q: Wear-resistant, high temperature, insulation materials which

- Epoxy, temperature from 100-400 degrees, processing more convenient. Ceramic is the best and cheap.

- Q: What is the thermal aging and electrical aging of insulating materials?

- Environmental aging, also known as atmospheric aging, is due to ultraviolet light, ozone, salt spray, acid and other factors caused by pollution of chemical aging, which is the main reason for ultraviolet light. Thermal aging more common in low-voltage electrical appliances, the mechanism is under the action of temperature, the insulating material in some volatile components escape, the internal components of oxidative cracking, thermal cracking, hydrolysis, molecular chain polymerization and other chemical changes, and gradually lose insulation properties.

- Q: What insulating material is best `?

- The earliest use of insulating materials is cotton, silk, mica, rubber and other natural products .20 century 30 years later, the rapid development of synthetic insulation materials, a variety of synthetic resin, plastic, etc. used in the field of electrical engineering to manufacture motor and high and low pressure Electrical appliances, so that the capacity of electrical products continue to expand, the volume gradually reduced, so as to promote the development of electrical and electronic technology.

Send your message to us

Mica Parts Used for Microwave Ovens Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords