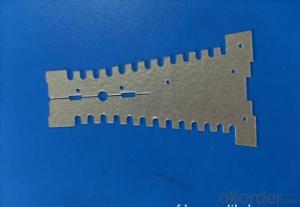

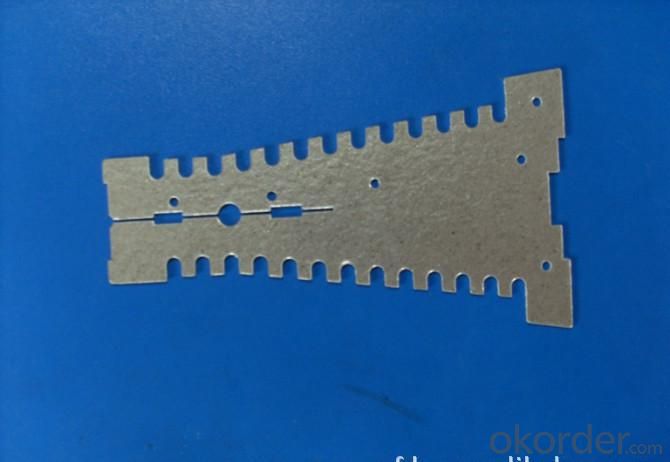

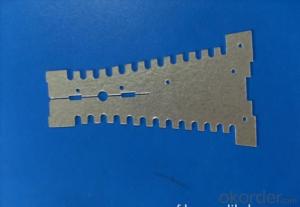

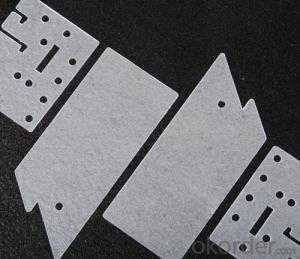

Special Sized Mica Plates Used in Electric Iron

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Introduction:

Mica is a rigid substrate able to withstand very high temperatures and are suited for applications up to 500°F (260°C).

Mica plate is made of mica paper with highperformance organic silicon resin. After heating and pressing, the mica plate can be made into rigid or flexible insulating plates. The mica content is about 90% and the organic silicon resin content is 10%.

2. Main features of Mica Parts:

Mica heating elements offer several distinct advantages over other flexible heater technologies, including extremely low leakage, lower material costs, and higher operating temperatures. Our mica heating element is made by detail order requirments.

3. Application:

Typical applications of mica heating elements are air heaters, enclosure systems, food service equipment, process and packaging equipment.

4. Technical Parameters:

MICA SHEET -----Technical data | ||||||||

ITEM | UNIT | RM | RP | RM-T | RP-T | FM | FP | |

Hardness |

| Rigid | Rigid | Rigid | Rigid | Flexible | Flexible | |

Mica paper |

| Muscovite | Phlogopite | Muscovite | Phlogopite | Muscovite | Phlogopite | |

Thickness | mm | 0.1-2.0 | 0.1-2.0 | 3.0-50 | 3.0-50 | 0.1-2.0 | 0.1-2.0 | |

Mica content | % | ≥90 | ≥90 | >88 | >88 | ≥90 | ≥90 | |

Bond Content | % | <10< span=""> | <10< span=""> | <12< span=""> | <12< span=""> | <10< span=""> | <10< span=""> | |

Density | g/m 3 | 1.6~2.45 | 1.6~2.45 | 2.1~2.4 | 2.1~2.4 | 1.6~2.45 | 1.6~2.45 | |

Heat | Continuous | ℃ | 500 | 700 | 500 | 700 | 500 | 700 |

Peak | ℃ | 700 | 900 | 700 | 900 | 700 | 900 | |

Heat loss at 500℃ | % | <1< span=""> | <1< span=""> | <1< span=""> | <2< span=""> | <1< span=""> | <1< span=""> | |

Heat loss at 700℃ | % | <2< span=""> | <2< span=""> | <1< span=""> | <2< span=""> | <2< span=""> | <2< span=""> | |

Flexural strength | Mpa | >160 | >140 | — | — | <1< span=""> | <1< span=""> | |

Water absorption 24h/23°C | % | <1< span=""> | <1< span=""> | <1< span=""> | <2< span=""> | — | — | |

Dielectric strength | KV/mm | >20 | >20 | >15 | >15 | >15 | >15 | |

Volume | 23℃ | ΩNaN | >1017 | >1017 | >1017 | >1017 | — | — |

500℃ | ΩNaN | >1012 | >1012 | >1012 | >1012 | — | — | |

Smoking Test | s | <4< span=""> | <4< span=""> | — | — | — | — | |

FAQ

We have organized several common questions for our clients,may help you sincerely:

--------What is the use of mica parts?

Mica laminate and washers made of our own high quality mica plates are used for home appliances, electro-magnets, micro-sensitive control gear etc

---------Which type of mica parts we can produce?

1. Rigid mica parts or Flexible mica parts

2. Muscovite mica parts or phlogopite mica parts

3. Thin mica parts or thick mica parts

4. All the special sized mica parts need drawing.

----------what advantages of mica parts?

1. Good high voltage insulation materials

2. Do not easily break up

3. Easily produce special size

- Q: The electrical equipment in the classroom which uses insulating material

- The use of insulating materials in the classroom electrical equipment: wires, screwdrivers, pliers, sockets, switches, lampholders, lamps, bulbs, motors.

- Q: What is the electrical performance of insulating materials

- The electrical insulating material is a material that is electrically insulated from the device and has a certain mechanical strength, typically having a resistivity of 106 to 1019.cm. Their function in electrical technology is as follows: 1 Insulate the conductor from the other parts; 2 Separate the conductors of different potentials 3 Provide the conditions for the energy storage of the capacitor 4 Improve the potential gradient in the high voltage electric field.

- Q: What type of enameled wire and insulation material is used for the compressor

- Small and medium-sized closed, semi-enclosed refrigeration compressors are used for the specific enameled wire specifically (QF) series.

- Q: What insulating material is used for high voltage cables

- Features: The rated voltage of the cable is 6kv. The long-term operating temperature of the cable is + 65 ° C. The minimum bend radius of the cable is 6 times the cable diameter.

- Q: What insulating materials are used for high frequency transformers?

- Where the water is mainly a resin and solvent or resin, oil and solvent composition, is based on polymer polymer, under certain conditions can be cured into an insulating film or insulation of the important insulation material, applied to high-frequency transformers After the surface, the solvent evaporates, the resin or the resin and the oil form a smooth film, showing the original pattern of the object. Easy to dry and durable, and can acid and oil.

- Q: What is the insulating material in the middle of the connecting wire?

- The original wire is insulated paint, you often use, you can also use quick-drying insulating paint.

- Q: What are the commonly used insulating materials?

- Mostly used to make insulating varnishes, winding wires, etc. Insulation materials are made of the above two kinds of materials made of various molding insulation materials, used as electrical appliances of the base, shell and so on.

- Q: Wear-resistant, high temperature, insulation materials which

- Epoxy, temperature from 100-400 degrees, processing more convenient. Ceramic is the best and cheap.

- Q: What are the electrical insulation materials

- Electrical insulation materials are wood, cotton, paper, oily paint, asphalt paint, polyester film, glass cloth, mica, glass fiber, asbestos, composite silicon organic polyester paint, quartz, glass, porcelain material.

- Q: What insulating material is best `?

- The earliest use of insulating materials is cotton, silk, mica, rubber and other natural products .20 century 30 years later, the rapid development of synthetic insulation materials, a variety of synthetic resin, plastic, etc. used in the field of electrical engineering to manufacture motor and high and low pressure Electrical appliances, so that the capacity of electrical products continue to expand, the volume gradually reduced, so as to promote the development of electrical and electronic technology.

Send your message to us

Special Sized Mica Plates Used in Electric Iron

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches