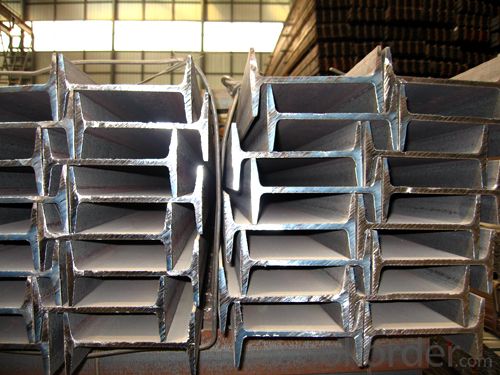

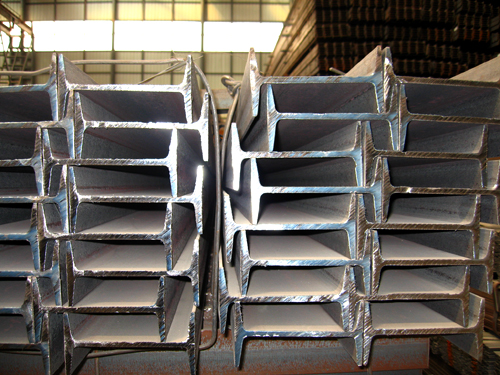

Metal Structure Steel I-beam High Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4000 PCS

- Supply Capability:

- 4000000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Quality Structural Steel I-Beam

OKorder is offering High Quality Structural Steel I-Beams at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

High Quality Structural Steel I-Beams are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel I-Beams are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (7-10 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Grade: Q235B, SM490, SS400, Q235B, Q345, Q345B

Production Process: Rolling cross-section

Dimensions:

Leg Height: 46 – 220mm

Depth: 50 – 180mm

Thickness: 4.5 – 17mm

Length: 6m – 12m

Production: 500 tons/month

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: Can steel I-beams be used in sports stadium construction?

- Yes, steel I-beams can be used in sports stadium construction. They are commonly used due to their strength, durability, and versatility, offering structural support for large spans and heavy loads required in stadium designs. I-beams are often utilized in the construction of stadium roofs, seating areas, and other structural components.

- Q: Welding problems of two I-beam combinations

- First, in the front, middle and back of the steel welding joint, fix the steel structure, and then according to the first in the middle and the two sides of the welding sequence welding (intermittent welding), if better control deformation, it is best to weld both sides at the same time

- Q: How do steel I-beams contribute to the overall stability and strength of a structure?

- Several factors contribute to the overall stability and strength of a structure, thanks to steel I-beams. To begin with, their distinct "I" shape offers exceptional resistance to bending forces. This enables I-beams to support heavy loads and evenly distribute them along their length, minimizing the risk of sagging or collapsing. Furthermore, the usage of steel as the material for I-beams enhances their strength. Steel is renowned for its high tensile strength, which means it can withstand stretching or breaking when subjected to heavy loads. This quality allows I-beams to endure substantial pressure without deforming or failing, ensuring the structural integrity of the entire building. Moreover, the design of I-beams allows for efficient material usage. The top and bottom flanges of the beam are wider and thicker than the vertical web in the center. This arrangement maximizes the beam's resistance to bending forces while minimizing the weight of the overall structure. The lightweight nature of steel I-beams simplifies their handling during construction, ultimately reducing costs and labor requirements. Additionally, the versatility of steel I-beams contributes to the overall stability of a structure. Engineers have the ability to adjust the size and shape of the beams to meet the specific requirements of the building, ensuring optimal performance and load-bearing capacity. This flexibility allows for the creation of intricate architectural designs while maintaining structural integrity. In conclusion, steel I-beams play a crucial role in enhancing the overall stability and strength of a structure. Their unique shape, high tensile strength, efficient material usage, and versatility make them an essential component in modern construction. By enabling buildings to withstand heavy loads and ensuring the safety of their occupants, steel I-beams are indispensable in the field of construction.

- Q: What is the average lifespan of a steel I-beam?

- The average lifespan of a steel I-beam can vary depending on a range of factors such as the quality of the steel used, the environment in which it is installed, and the level of maintenance it receives. Generally, a well-maintained steel I-beam can last for several decades or even longer. With regular inspections, proper cleaning, and adequate protection against corrosion, a steel I-beam can have a lifespan of 50 years or more. However, in harsh environments with high levels of moisture, salt, or chemical exposure, the lifespan may be significantly shorter. It is important to consult with structural engineers and follow manufacturer guidelines to ensure the longevity of the steel I-beam.

- Q: How do you calculate the moment of inertia for steel I-beams?

- In order to determine the moment of inertia for steel I-beams, one must take into account the specific dimensions and shape of the beam. The moment of inertia measures the object's resistance to rotational motion around a specific axis. For I-beams, the moment of inertia refers to their resistance to bending or flexing around their central axis. The moment of inertia formula for an I-beam can be derived using basic principles of calculus. It involves dividing the beam into smaller sections and summing up the contributions from each section. The moment of inertia is influenced by the beam's cross-sectional shape and dimensions, particularly the area and the distance from the centroid or neutral axis. To calculate the moment of inertia for an I-beam, the following formula can be used: I = (b1 * h1^3) / 12 + (b2 * h2^3) / 12 + (2 * A * d^2) Where: - I represents the moment of inertia - b1 and h1 represent the width and height of the top flange - b2 and h2 represent the width and height of the bottom flange - A represents the area of the web (the vertical section connecting the two flanges) - d represents the distance from the centroid of the web to the centroid of the top flange To calculate the moment of inertia, one must obtain or measure the dimensions of the I-beam, including the dimensions of the flanges (top and bottom) and the web. Once the measurements are obtained, they can be substituted into the formula to determine the moment of inertia. It is important to emphasize that the moment of inertia plays a crucial role in structural engineering. It helps determine the beam's ability to resist bending, deflection, and torsion, which are essential factors in designing structures that are safe and efficient.

- Q: How are steel I-beams protected against rust and corrosion during storage?

- To prevent rust and corrosion during storage, steel I-beams are commonly safeguarded using various methods. One such method involves applying a protective coating, such as paint or galvanizing, which acts as a barrier between the steel and the environment. This barrier effectively hinders the formation of rust and corrosion by preventing direct contact between the metal surface and moisture or oxygen. When using paint as a protective coating, a layer of primer is typically applied first to improve adhesion and corrosion resistance. This is then followed by one or more layers of paint to provide additional protection. The choice of paint type and quality depends on factors such as the duration of storage and expected environmental conditions. Alternatively, galvanizing is widely employed to protect steel I-beams. This process involves coating the steel with a layer of zinc through hot-dip galvanizing or electroplating. Zinc acts as a sacrificial anode, corroding before the steel does. This sacrificial corrosion process effectively safeguards the steel against rust and corrosion. In addition to protective coatings, steel I-beams can be stored in controlled environments with reduced humidity levels or in specially designed storage facilities that minimize exposure to moisture and corrosive elements. Regular inspections and maintenance are essential to detect and address any signs of rust or corrosion that may occur despite these preventive measures. Overall, a combination of protective coatings, controlled environments, and proper maintenance practices ensures that steel I-beams remain free from rust and corrosion during storage.

- Q: Are steel I-beams environmentally friendly?

- When compared to other construction materials, steel I-beams can be seen as relatively environmentally friendly. The reason for this is that steel is a highly recyclable material, and the production of steel I-beams often incorporates a significant amount of recycled content. Moreover, steel is known for its durability and long lifespan, which means that steel I-beams necessitate less maintenance and replacement as time goes on. Consequently, this reduces the overall environmental impact of construction and minimizes waste. However, it is crucial to take into account the energy-intensive process involved in manufacturing steel, which can contribute to greenhouse gas emissions. Nevertheless, the recyclability and durability of steel I-beams make them a favored choice for many construction projects that strive to achieve sustainability objectives.

- Q: Can steel I-beams be used in schools or educational facilities?

- Yes, steel I-beams can be used in schools or educational facilities. Steel I-beams are commonly used in construction due to their strength and durability. They provide structural support and can be used to create open and spacious areas without the need for excessive columns or walls. Additionally, steel I-beams can withstand heavy loads and are fire-resistant, making them a suitable choice for ensuring the safety and longevity of educational buildings.

- Q: How do steel I-beams perform in terms of deflection and sagging?

- The excellent performance of steel I-beams in terms of deflection and sagging is widely recognized. This is due to their distinctive shape, which features a vertical web and horizontal flanges. As a result of this design, they have a remarkable resistance to bending and can support heavy loads without experiencing significant deflection or sagging. The distribution of load along the length of the beam is achieved through the design of I-beams. This design minimizes the amount of deflection that occurs. The vertical web contributes most of the beam's strength, while the horizontal flanges assist in resisting bending forces. This structural configuration ensures that I-beams can endure substantial weight and pressure without excessive bending or sagging. Furthermore, steel is an incredibly strong and durable material, making it an ideal choice for constructing I-beams. Its high tensile strength allows steel I-beams to handle heavy loads and resist deformation. This strength enables them to maintain their shape and prevent excessive deflection or sagging. Additionally, steel I-beams are frequently utilized in construction projects due to their high stiffness-to-weight ratio. This means that they are relatively lightweight in comparison to the weight they can support. The combination of their robust structural design and the inherent strength of steel allows I-beams to uphold their rigidity and prevent excessive deflection, even when subjected to significant loads. In conclusion, steel I-beams are highly effective when it comes to deflection and sagging. Their unique shape, along with the strength and durability of steel, allows them to support heavy loads and minimize any deformation or sagging that may occur. Consequently, they are a popular choice for various construction applications where maintaining structural integrity is crucial.

- Q: Can steel I-beams be used in earthquake-prone areas?

- Yes, steel I-beams can be used in earthquake-prone areas. In fact, steel is often the preferred material for structural elements in earthquake-resistant buildings. Steel I-beams have several advantages that make them suitable for these areas. Firstly, steel is known for its high strength and ductility, which allows it to withstand the forces generated during an earthquake. Secondly, I-beams have a shape that provides excellent structural integrity, distributing the load evenly and reducing the risk of collapse. Additionally, steel I-beams have the ability to flex and absorb energy during an earthquake, which helps to dissipate the seismic forces and protect the overall structural integrity of the building. Proper engineering and design considerations, including proper connections and reinforcements, are crucial to ensure the optimal performance of steel I-beams in earthquake-prone areas.

Send your message to us

Metal Structure Steel I-beam High Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4000 PCS

- Supply Capability:

- 4000000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords