Monolithic Refractories for Iron and Steel Industry - Ladle Shroud Long Nozzle Chinese Steelmaking

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Steelmaking long nozzle /refractory materials/refractory nozzles

steelmaking zircon nozzle Zr content 94-95% , and nozzle with metal shell ,

can protect nozzle burst.the casting temperature normally at 1520-1580 ℃.

our zirconia cores temperature resistance up to 2000℃, density is 4.2g/cm3 .

Steelmaking tundish nozzle zircon core contact face made a little big than other,effectively protect the nozzle using life.

tundish zirconia nozzles materials is alumina-zirconia-carbon .composed by Alumina-Carbon Shell, and zirconia core.

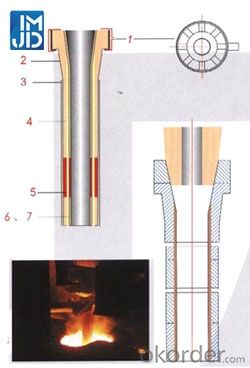

Graphic illustration:

1.Argon injection structure depending on customer specifications.

2.Ceramic glaze layer to prevent the material oxidation effectively.

3.Ceramic fiber blanket to prevent heat lost during casting.

4.High quality Al-C materials having high corrosion and thermal shock resistance.

5.High quality Zr-based composite to provide high corrosion resistance at the slag line.

6.Non-graphite based mased materials to meet the requirements of producing low carbon steel,silicon steel and high purity steel.

Manufacturing and QC

1.Raw materials blending

Independent raw materials blending center to assurestrict control of materials quality.

2.Shaping

Isostatic pressing technoloty,with as 1000 tons of pressure to assure the homogenous bulk density of each product.

3.Machining

To assure the uniform shape,dimension and dimension tolerance of each product.

4.X-ray defect inspection

To assure all products supplied to our customers without any defect and to prevent the un-countable feconomic loss for our customers.

5.Physical and chemistry analysis

To assure all products meet the physical and chemistry characteristics.

6.Packaging

The world-class for packaging to assure the safety transportation.

- Q: How are monolithic refractories inspected and tested for quality assurance?

- To ensure the reliability and performance of monolithic refractories, a series of rigorous processes are conducted for quality assurance. These inspections and tests play a crucial role in maintaining consistent quality standards and identifying any potential defects or weaknesses in the refractory material. The first step involves conducting visual inspections to check for visible defects such as cracks, spalling, or signs of poor manufacturing. This helps in identifying any obvious issues that may affect the refractory's performance. Following that, specialized equipment is used to measure physical properties such as density, porosity, and thermal conductivity. These measurements are then compared against predetermined standards to ensure that the refractory material meets the required specifications. Density and porosity are important indicators of the refractory's strength and resistance to heat and chemicals, while thermal conductivity determines its ability to efficiently transfer heat. Moreover, mechanical tests are performed to assess the refractory's strength and resistance to mechanical stress. This involves subjecting the material to compressive, tensile, and flexural forces to evaluate its structural integrity and durability. To ensure the refractory's suitability for high-temperature environments, thermal tests are conducted. These tests involve exposing the refractory to extreme temperatures and monitoring its behavior. Parameters such as thermal expansion and shrinkage, resistance to thermal shock, and thermal cycling are evaluated during these tests. Chemical analysis is another important aspect of quality assurance for monolithic refractories. Samples of the refractory material are analyzed to determine their chemical composition and assess their resistance to various corrosive environments. This analysis helps ensure that the refractory is suitable for the specific applications it will be used in. Finally, field tests may be conducted at actual operating sites to evaluate the refractory's performance under real-world conditions. These tests involve monitoring the refractory's behavior in terms of wear and tear, thermal insulation, and resistance to chemical attack. The results obtained from field tests are crucial in validating the refractory's performance and making any necessary adjustments to the manufacturing process. In conclusion, monolithic refractories undergo a comprehensive inspection and testing process that includes visual inspections, physical and mechanical tests, thermal analysis, chemical analysis, and field tests. This systematic approach guarantees that the refractories meet the required quality standards, providing reliability and durability in the demanding environments they are designed for.

- Q: How do monolithic refractories contribute to the overall efficiency of ladle transfer processes?

- Monolithic refractories play a crucial role in enhancing the overall efficiency of ladle transfer processes. These refractories are made of a single, homogeneous material, which allows for easy installation and maintenance. This feature significantly reduces downtime during the ladle transfer process, resulting in increased productivity. One way monolithic refractories contribute to efficiency is through their high thermal conductivity. Ladle transfer processes involve the transfer of molten metal, which generates immense heat. Monolithic refractories have excellent heat resistance, ensuring that they can withstand the extreme temperatures of the molten metal. This property prevents refractory failure and prolongs the lifespan of the ladle, leading to more efficient and uninterrupted ladle transfer operations. Additionally, monolithic refractories offer superior corrosion resistance. The corrosive nature of molten metal can cause significant damage to ladles over time. However, monolithic refractories are designed to withstand chemical attacks from molten metal, preventing the degradation of the ladle's integrity. As a result, ladles lined with monolithic refractories have a longer lifespan and require less frequent replacement, leading to cost savings and improved efficiency. Furthermore, the ability of monolithic refractories to conform to complex shapes and designs is another contributing factor to the efficiency of ladle transfer processes. Ladles come in various sizes and shapes, and the use of monolithic refractories allows for customized linings that perfectly fit the ladle's dimensions. This precise fit minimizes heat loss and maximizes energy efficiency during ladle transfer processes. Moreover, monolithic refractories offer excellent mechanical strength and resistance to thermal shock. Ladle transfer processes involve the handling and movement of ladles, which can subject refractories to mechanical stresses. The outstanding mechanical properties of monolithic refractories ensure their durability and prevent cracking or spalling, reducing the risk of refractory failure and improving the efficiency of ladle transfer operations. In summary, monolithic refractories contribute to the overall efficiency of ladle transfer processes by providing high thermal conductivity, corrosion resistance, precise lining fit, and excellent mechanical properties. These refractories enhance the ladle's durability, reduce downtime, and improve energy efficiency, resulting in cost savings and increased productivity in the steelmaking industry.

- Q: How do monolithic refractories withstand the chemical attacks in aluminum furnace applications?

- Monolithic refractories withstand chemical attacks in aluminum furnace applications due to their high resistance to oxidation and corrosion. They are specifically designed to withstand the harsh environment of aluminum processing, which involves exposure to molten aluminum, alkaline fluxes, and other corrosive chemicals. Monolithic refractories have excellent chemical stability, low porosity, and high thermal shock resistance, which allows them to maintain their structural integrity and protect the furnace lining from chemical erosion. Additionally, these refractories often contain additives such as antioxidants and anti-corrosion agents that further enhance their resistance to chemical attacks in aluminum furnace applications.

- Q: What are the challenges in recycling and disposing of monolithic refractories?

- Recycling and disposing of monolithic refractories pose several challenges that need to be addressed in order to minimize environmental impact and maximize resource efficiency. One of the main challenges is the handling and transportation of monolithic refractories due to their heavy and bulky nature. These materials are often used in high-temperature applications, such as furnace linings, and can be difficult to dismantle and remove from equipment. The weight and size of monolithic refractories make it challenging to transport them to recycling or disposal facilities, requiring specialized equipment and infrastructure. Another challenge is the heterogeneity of monolithic refractories, which often contain various types of refractory materials, binders, and additives. This complexity makes it difficult to separate and categorize different components for effective recycling. The lack of standardized recycling processes for monolithic refractories further complicates the recycling efforts. Furthermore, the high melting points of refractory materials used in monolithic refractories can make it energy-intensive and costly to recycle them through conventional methods like melting and remolding. Alternative recycling methods, such as thermal treatment or chemical processing, need to be explored and optimized to make the recycling process more economically and environmentally viable. Ensuring the proper disposal of monolithic refractories is also a challenge. If these materials are not recycled, they often end up in landfills, taking up valuable space and potentially leaching harmful substances into the environment. Landfilling refractories can also pose a risk of contamination if they are not properly managed or if hazardous additives are present in the materials. To address these challenges, it is crucial to invest in research and development to develop more efficient and cost-effective recycling technologies for monolithic refractories. Collaboration between manufacturers, recycling facilities, and regulatory bodies is also essential to establish guidelines and standards for the recycling and disposal of these materials. Additionally, educating industries and end-users about the importance of recycling and the availability of recycling options can help increase the demand and feasibility of recycling monolithic refractories.

- Q: How are monolithic refractories repaired or replaced in iron and steel facilities?

- Monolithic refractories in iron and steel facilities are repaired or replaced through a process known as hot repair or hot gunning. This involves using specialized equipment to heat the damaged refractory material and remove it. The area is then prepared for new refractory installation, which is done by either shotcreting or gunning the new material onto the surface. This method allows for quick repairs and replacements, minimizing downtime and ensuring the efficiency and safety of the facility.

- Q: What are the key differences between acidic and basic monolithic refractories?

- The key differences between acidic and basic monolithic refractories lie in their chemical compositions and their behavior in different environments. Acidic monolithic refractories are primarily composed of acidic oxides such as silica (SiO2) or alumina (Al2O3). These materials have a high resistance to acidic environments and are commonly used in industries where they come into contact with acidic gases or liquids. Acidic refractories are characterized by their ability to withstand high temperatures and resist chemical erosion. They are generally not suitable for use in basic or alkaline conditions, as they can react with basic compounds and lose their effectiveness. On the other hand, basic monolithic refractories are composed of basic oxides such as magnesia (MgO) or dolomite (MgO-CaO). These materials have a high resistance to basic or alkaline environments and are commonly used in industries where they come into contact with basic compounds such as lime or cement. Basic refractories are characterized by their ability to withstand high temperatures and resist chemical erosion from basic compounds. They are generally not suitable for use in acidic conditions, as they can react with acidic compounds and lose their effectiveness. In terms of their physical properties, acidic monolithic refractories tend to have higher melting points and better thermal shock resistance compared to basic monolithic refractories. This is due to the higher melting points of acidic oxides and their ability to form stable silicate or aluminate structures at high temperatures. On the other hand, basic monolithic refractories generally have higher density and better resistance to penetration by molten materials. In conclusion, the key differences between acidic and basic monolithic refractories lie in their chemical compositions and their behavior in different environments. Acidic refractories are suitable for acidic conditions, have higher melting points, and better thermal shock resistance, while basic refractories are suitable for basic conditions, have higher density, and better resistance to penetration by molten materials.

- Q: How are monolithic refractories installed and repaired in iron and steel applications?

- Monolithic refractories in iron and steel applications are installed by carefully preparing the surface, followed by applying and compacting the refractory material using various techniques like gunning, casting, ramming, or shotcreting. In terms of repair, damaged sections are usually removed and replaced with fresh refractory material, ensuring proper bonding and compaction to restore the integrity of the lining. Regular inspections and maintenance are essential to identify and address any potential issues promptly.

- Q: How do monolithic refractories contribute to the quality of iron and steel products?

- Monolithic refractories play a crucial role in enhancing the quality of iron and steel products. These refractories are comprised of a single, solid structure, making them highly resistant to thermal and mechanical stresses. Their unique properties make them well-suited for various high-temperature applications in the iron and steel industry. Firstly, monolithic refractories provide excellent thermal insulation, which helps to maintain a consistent temperature within the furnace or kiln. This stability in temperature is essential for the proper heat treatment of iron and steel, ensuring optimal metallurgical properties and reducing the risk of defects. By preventing heat loss, monolithic refractories enable efficient energy utilization, leading to cost savings and environmental benefits. Another significant contribution of monolithic refractories lies in their ability to withstand harsh operating conditions. The iron and steel manufacturing process involves extreme temperatures, aggressive chemical environments, and mechanical stresses. Monolithic refractories exhibit exceptional resistance to these conditions, ensuring durability and longevity. Their high resistance to thermal shock prevents cracking or spalling, which can lead to contamination and compromised product quality. Furthermore, monolithic refractories offer excellent corrosion resistance, protecting the iron and steel products from chemical reactions with molten metal, slag, and other aggressive substances. This resistance not only preserves the integrity of the refractory lining but also prevents contamination of the metal, resulting in improved product quality. Monolithic refractories also enable flexibility in design and installation. They can be shaped, cast, or gunned into various complex geometries, allowing for customization according to the specific requirements of the iron and steel production process. This versatility ensures optimal lining performance, maximizing efficiency and product quality. Overall, monolithic refractories contribute significantly to the quality of iron and steel products through their thermal insulation properties, resistance to harsh operating conditions, corrosion resistance, and design flexibility. By providing a reliable and durable lining in high-temperature applications, monolithic refractories help to ensure consistent and high-quality output in the iron and steel industry.

- Q: How do monolithic refractories contribute to the reduction of downtime in iron and steel plants?

- Monolithic refractories play a crucial role in reducing downtime in iron and steel plants due to their unique properties and applications. These refractories are composed of a single, uniform material, making them highly versatile and easier to install compared to traditional brick refractories. Firstly, monolithic refractories offer excellent thermal insulation, which helps to prevent heat loss and maintain high temperatures in various areas of the plant. This insulation capability reduces the need for frequent repairs and replacements, as it minimizes thermal stress and prolongs the lifespan of equipment and furnaces. This, in turn, results in less downtime required for maintenance and repair work. Secondly, monolithic refractories exhibit superior resistance to thermal shock. The extreme temperatures experienced in iron and steel plants can cause rapid and significant temperature changes, leading to the cracking and failure of refractory linings. However, monolithic refractories have better thermal shock resistance, enabling them to withstand sudden temperature fluctuations without sustaining damage. This property enhances their durability and contributes to the reduction of downtime. Moreover, monolithic refractories offer enhanced mechanical strength and chemical resistance, making them suitable for the harsh operating conditions in iron and steel plants. These refractories can withstand the erosive effects of molten metal, slag, and other corrosive materials, ensuring the longevity of equipment and reducing the frequency of maintenance interventions. Additionally, the installation process of monolithic refractories is faster and more efficient compared to brick refractories. They can be easily applied using various techniques, such as shotcreting or gunning, allowing for quick repairs or renovations during planned shutdowns or even emergency situations. The reduced installation time results in shorter downtime periods, enabling the plant to resume operations promptly. In conclusion, monolithic refractories significantly contribute to the reduction of downtime in iron and steel plants through their excellent thermal insulation, resistance to thermal shock, mechanical strength, and chemical resistance. Their ease of installation and quick repair capabilities further enhance their role in minimizing downtime and ensuring uninterrupted production in these critical industries.

- Q: What are the key factors affecting the installation and curing of monolithic refractories?

- There are several key factors that affect the installation and curing of monolithic refractories: 1. Material selection: The choice of monolithic refractory material is crucial as it determines the installation and curing process. Different materials have different installation and curing requirements, so it is important to select the right material for the specific application. 2. Surface preparation: Proper surface preparation is essential for the successful installation and curing of monolithic refractories. The surface should be clean, free from contaminants, and properly roughened to ensure good adhesion of the refractory material. 3. Mixing and proportioning: The mixing and proportioning of the refractory material play a significant role in its installation and curing. It is important to follow the manufacturer's instructions for mixing ratios and ensure thorough mixing to achieve a homogeneous mixture. 4. Application technique: The technique used to apply the monolithic refractory material can greatly impact its installation and curing. Proper application techniques, such as gunning, casting, or ramming, should be employed to ensure uniformity and proper bonding with the substrate. 5. Temperature control: Temperature control during the installation and curing process is critical for the development of desired properties in the monolithic refractory. The curing process should be carried out at the recommended temperature, and any sudden temperature changes should be avoided to prevent thermal stresses. 6. Moisture content: The moisture content of the refractory material and the surrounding environment can affect its installation and curing. Excessive moisture can lead to shrinkage, cracking, or poor bonding, while insufficient moisture can hinder proper curing. It is important to maintain the optimum moisture content for the specific refractory material. 7. Curing time: The curing time required for monolithic refractories varies depending on the material and application. It is crucial to follow the recommended curing time to allow for proper strength development and dimensional stability. 8. Environmental conditions: Environmental factors, such as humidity, temperature, and air circulation, can influence the installation and curing of monolithic refractories. Suitable environmental conditions should be maintained to facilitate proper drying and curing. Overall, understanding and addressing these key factors can ensure the successful installation and curing of monolithic refractories, leading to improved performance and longevity of the refractory lining.

Send your message to us

Monolithic Refractories for Iron and Steel Industry - Ladle Shroud Long Nozzle Chinese Steelmaking

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords