Al2O3-SiO2-C Castable for Blast Furnace Tapping Channel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Al2O3-SiO2-C Castable for Blast Furnace Tapping Channel

FIREF Al2O3- SiO2-C castable for blast furnace tapping channel is known for its excellent corrosion and scouring resistance of iron steel which is made strictly as per international standards. Beside, FIREF Al2O3- SiO2-C castable for blast furnace tapping channel has gained a good fame for its long operating life and easy execution and mending.

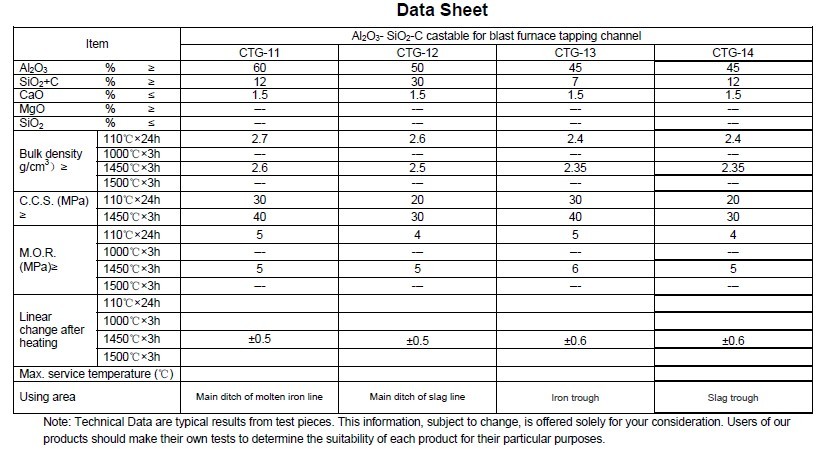

Technical data of Al2O3-SiO2-C Castable for Blast Furnace Tapping Channel

Production line and packing of Al2O3-SiO2-C Castable for Blast Furnace Tapping Channel

Feature of Al2O3-SiO2-C Castable for Blast Furnace Tapping Channel

Long operating life

Excellent corrosion and scouring resistance of iron steel

Easy execution and mending

Application of Al2O3-SiO2-C Castable for Blast Furnace Tapping Channel

FIREF Al2O3-SiO2-C castable for blast furnace tapping channel can be used widely for in situ casting or pre-casting for tri-angle area of UHP EAF roof.

Production Flow of Al2O3-SiO2-C Castable for Blast Furnace Tapping Channel

- Q:How do monolithic refractories resist chemical attacks from molten metals and slag?

- Monolithic refractories are engineered to withstand chemical attacks caused by molten metals and slag. They possess various essential qualities that enable them to endure such harsh conditions. To begin with, monolithic refractories comprise top-notch materials with exceptional chemical resistance. These materials, including alumina, magnesia, and chrome, have a high melting point and remain stable even when exposed to extreme temperatures and corrosive substances. This chemical stability ensures that the refractory maintains its integrity and structural strength when in contact with molten metals and slag. Moreover, monolithic refractories have a compact and dense structure. This microstructure serves as a barrier, preventing molten metals and slag from penetrating the refractory material. By limiting the contact between the corrosive substances and the refractory, the dense structure reduces the likelihood of chemical reactions and erosion, thereby enhancing the refractory's resistance to chemical attacks. Additionally, monolithic refractories often contain additives and binders that enhance their chemical resistance. These additives form a protective layer on the refractory surface, acting as a shield against chemical attacks. They can also react with certain corrosive substances, forming stable compounds that further inhibit the penetration and corrosion of the refractory material. Furthermore, monolithic refractories are designed to have minimal porosity. This low porosity minimizes the absorption of molten metals and slag, preventing them from infiltrating the refractory and causing damage. By reducing the permeability of the material, the refractory can maintain its structural integrity and resist chemical attacks for extended periods. In conclusion, monolithic refractories withstand chemical attacks from molten metals and slag due to their high-quality materials, dense structure, additives, and low porosity. These combined properties enable the refractories to endure aggressive environments and maintain their performance and longevity in industrial applications.

- Q:How do monolithic refractories improve the efficiency of ladle and tundish drying furnaces?

- Monolithic refractories improve the efficiency of ladle and tundish drying furnaces by providing excellent thermal insulation, high resistance to thermal shock, and superior strength. These properties ensure minimal heat loss during the drying process, allowing for faster and more efficient heating. Additionally, monolithic refractories offer better resistance to erosion and corrosion, prolonging the lifespan of the furnaces and reducing maintenance requirements. Overall, the use of monolithic refractories enhances the performance and productivity of ladle and tundish drying furnaces.

- Q:How long is the lifespan of monolithic refractories in iron and steel applications?

- Several factors can influence the lifespan of monolithic refractories in iron and steel applications. These factors encompass the type of refractory material utilized, the specific application, the operational conditions, and the implemented maintenance practices. Monolithic refractories employed in iron and steel applications are generally engineered to endure high temperatures, thermal shock, chemical attack, and mechanical stress. When compared to other refractory materials, they are expected to possess a relatively extended lifespan. Under normal operating conditions and with appropriate maintenance, monolithic refractories can typically endure anywhere from several months to several years in iron and steel applications. Nevertheless, it is important to acknowledge that certain areas of the application may be subjected to more severe conditions, necessitating more frequent repairs or replacements. Regular inspections and monitoring of the refractories' condition are vital in order to detect any signs of deterioration or damage. Any necessary repairs or replacements should be promptly executed to prevent further damage and reduce downtime. It is also noteworthy to mention that advancements in refractory technology and materials have resulted in the development of more resilient and durable monolithic refractories. These advancements have extended the lifespan of refractories in iron and steel applications, ultimately enhancing the overall efficiency and productivity of the operations.

- Q:What are the advantages of using monolithic refractories in the iron and steel industry?

- Monolithic refractories offer several advantages in the iron and steel industry. Firstly, they provide excellent thermal insulation, helping to maintain high temperatures within the furnaces and kilns, ensuring efficient and consistent production processes. Secondly, monolithic refractories have high resistance to thermal shock and mechanical stress, making them durable and long-lasting in harsh operating conditions. Additionally, their ability to be easily shaped and installed reduces downtime during maintenance or repairs. Lastly, monolithic refractories have good chemical resistance, protecting against corrosive elements present in iron and steel production, thereby enhancing the overall performance and productivity of the industry.

- Q:How are monolithic refractories manufactured?

- Monolithic refractories are manufactured by combining various raw materials, such as aggregates, binders, and additives, with water to create a workable mixture. This mixture is then shaped into the desired form, either by casting, gunning, or ramming. Afterwards, the shaped refractory is dried and fired at high temperatures to achieve the desired strength and thermal properties. The manufacturing process of monolithic refractories allows for flexibility in design and installation, making them suitable for a wide range of applications.

- Q:How do monolithic refractories contribute to the quality of iron and steel products?

- Monolithic refractories play a crucial role in enhancing the quality of iron and steel products. These refractories are comprised of a single, solid structure, making them highly resistant to thermal and mechanical stresses. Their unique properties make them well-suited for various high-temperature applications in the iron and steel industry. Firstly, monolithic refractories provide excellent thermal insulation, which helps to maintain a consistent temperature within the furnace or kiln. This stability in temperature is essential for the proper heat treatment of iron and steel, ensuring optimal metallurgical properties and reducing the risk of defects. By preventing heat loss, monolithic refractories enable efficient energy utilization, leading to cost savings and environmental benefits. Another significant contribution of monolithic refractories lies in their ability to withstand harsh operating conditions. The iron and steel manufacturing process involves extreme temperatures, aggressive chemical environments, and mechanical stresses. Monolithic refractories exhibit exceptional resistance to these conditions, ensuring durability and longevity. Their high resistance to thermal shock prevents cracking or spalling, which can lead to contamination and compromised product quality. Furthermore, monolithic refractories offer excellent corrosion resistance, protecting the iron and steel products from chemical reactions with molten metal, slag, and other aggressive substances. This resistance not only preserves the integrity of the refractory lining but also prevents contamination of the metal, resulting in improved product quality. Monolithic refractories also enable flexibility in design and installation. They can be shaped, cast, or gunned into various complex geometries, allowing for customization according to the specific requirements of the iron and steel production process. This versatility ensures optimal lining performance, maximizing efficiency and product quality. Overall, monolithic refractories contribute significantly to the quality of iron and steel products through their thermal insulation properties, resistance to harsh operating conditions, corrosion resistance, and design flexibility. By providing a reliable and durable lining in high-temperature applications, monolithic refractories help to ensure consistent and high-quality output in the iron and steel industry.

- Q:How are monolithic refractories used in the iron and steel industry?

- Monolithic refractories are extensively used in the iron and steel industry for various applications due to their superior performance and versatility. These refractories are composed of a single, uniform material and are designed to be used as a seamless lining in high-temperature environments. In the iron and steel industry, monolithic refractories play a crucial role in different stages of the manufacturing process. One of the primary applications is in the blast furnace, where monolithic refractories are used to line the inside of the furnace. This lining is subjected to extremely high temperatures and harsh chemical reactions. Monolithic refractories provide excellent thermal insulation and resistance to chemical attack, ensuring the structural integrity and longevity of the blast furnace. Another important application is in the steelmaking process. Monolithic refractories are used to line the ladles and tundish, which are used to transport and pour molten steel. These refractories are specially designed to withstand the high temperatures and corrosive nature of the molten steel, preventing contamination and ensuring the quality of the final product. Moreover, monolithic refractories are also used in various ancillary equipment and structures in the iron and steel industry. They are employed in furnaces, kilns, and other heat treatment systems to provide insulation and maintain high-temperature conditions. Additionally, monolithic refractories are used in the construction of chimneys, exhaust ducts, and other exhaust systems, where they provide thermal insulation and resistance to corrosive gases. Overall, monolithic refractories play a vital role in the iron and steel industry by providing high-temperature insulation, chemical resistance, and durability. They help optimize the production process, improve energy efficiency, and ensure the quality of the final product. With their versatility and excellent performance, monolithic refractories have become an indispensable component in the iron and steel manufacturing industry.

- Q:How do monolithic refractories prevent slag penetration?

- Monolithic refractories prevent slag penetration through several mechanisms. Firstly, monolithic refractories are made up of high-quality materials that have excellent resistance to slag attack. These materials, such as alumina, silica, and magnesia, have a high melting point and can withstand the corrosive nature of the slag. Secondly, monolithic refractories are designed with a dense and compact structure that minimizes the porosity. Slag penetration occurs when the molten slag infiltrates the pores and cracks of the refractory material. By reducing the porosity, monolithic refractories create a barrier that restricts the entry of slag into the refractory lining. Additionally, monolithic refractories can be chemically bonded to the substrate, forming a strong and impermeable bond. This bond further enhances the resistance to slag penetration by preventing any gaps or weak points where the slag can penetrate. Moreover, monolithic refractories can be designed with a high thermal shock resistance. Slag penetration is often intensified by thermal cycling, where the refractory material undergoes rapid temperature changes. Monolithic refractories with high thermal shock resistance can withstand these temperature fluctuations without cracking or spalling, thus reducing the risk of slag penetration. Furthermore, the proper installation and maintenance of monolithic refractories play a crucial role in ensuring their effectiveness against slag penetration. The refractory lining needs to be properly designed, using appropriate thickness and geometry, to provide maximum protection against slag attack. Regular inspection and repair of any damaged or worn-out areas can also prevent slag penetration. In conclusion, monolithic refractories prevent slag penetration through their excellent resistance to slag attack, dense structure, chemical bonding, high thermal shock resistance, and proper installation and maintenance. These factors work together to create a strong and impermeable barrier that protects the underlying substrate from the corrosive effects of slag.

- Q:What are the recommended drying procedures for monolithic refractories?

- The recommended drying procedures for monolithic refractories typically involve a gradual and controlled process to ensure the refractory material is properly cured and hardened. This typically includes a pre-drying phase where the refractory is heated slowly to remove any residual moisture. After pre-drying, a gradual increase in temperature is applied to further remove moisture and allow for proper chemical reactions to occur within the refractory. It is important to closely follow manufacturer guidelines and consider factors such as refractory thickness, ambient humidity, and available drying equipment to determine the specific drying procedures for each application.

- Q:How do monolithic refractories improve the efficiency of ladle and tundish drying systems?

- Monolithic refractories improve the efficiency of ladle and tundish drying systems by providing superior thermal insulation, reduced heat loss, and increased resistance to thermal shock. These refractories have high thermal conductivity and low heat capacity, enabling faster and more uniform heating of the ladle and tundish. Additionally, their monolithic nature eliminates joints and seams that could lead to heat leakage, ensuring better heat retention and improved energy efficiency. The enhanced thermal properties of monolithic refractories contribute to quicker drying times and reduced energy consumption in ladle and tundish drying processes, ultimately improving overall system efficiency.

1. Manufacturer Overview |

|

|---|---|

| Location | Henan, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 60 Million |

| Main Markets | Mid East; Eastern Europe; North America |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 31% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | Above 36,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Al2O3-SiO2-C Castable for Blast Furnace Tapping Channel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords