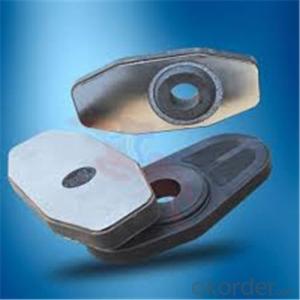

Monolithic Refractories High Temperature Ladle Sliding Gate for Iron and Steel Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for High Performance Refractory Ladle Slide Gate

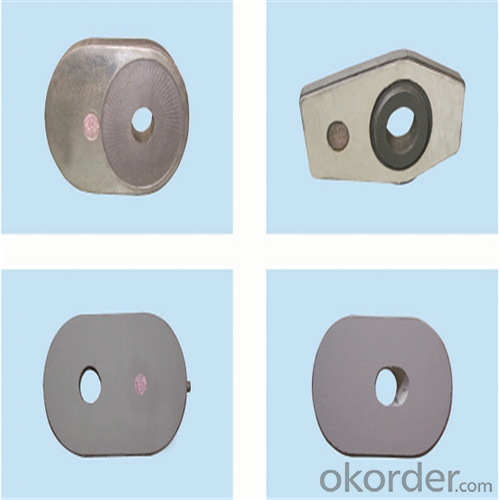

| Place of Origin: | China (Mainland) | Shape: | Plate | Material: | Alumina Block |

| SiO2 Content (%): | N/A | Al2O3 Content (%): | 80-90% | MgO Content (%): | N/A |

| CaO Content (%): | N/A | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | N/A |

| SiC Content (%): | N/A | Model Number: | CS80 | Brand Name: | |

| Product name: | High performance refractory ladle slide gate | Model No.: | cs80 | Brand name: | CMAX |

| Quality: | Al-C or Al-Zr-C | Service life: | 4-6 heats | Apparent porosity: | 7% Max |

| Bulk density:: | 3.1 MIN | C.C.S: | 120MPA | MOQ: | 100 pcs for trial |

| Delivery time: | 60 working days upon receipt of deposit |

Packaging & Delivery

| Packaging Details: | Inner carton packing, outer wooden case suitable for long term sea shipping |

| Delivery Detail: | three months working days upon receipt of deposit |

Specifications

Surface flatness less than 0.05mm

High mechanical strength

Erosion resistance

Oxidation resistance

Thermal shock stability

General Chemical Analysis for refractory ladle slide gate :

slide gate plate widely including Alumina carbon and Alumina Zirconia Carbon slide gate plate, MgO and MgO-spinel slide gate plate,nonoxides bonding slide gate plateand unburned slide gate plate.

Alumina -Zirconia-Carbon material

| Al-Zr-C Material | |||||

| Al2O3 | C | ZrO2 | Apparent porosity | Bulk density | C.C.S |

| (% minm) | (% minm) | (% minm) | (% max) | (gm./cc minm) | (MPa minm) |

| 85 | 3 | 5 | 7 | 3.1 | 120 |

| 85 | 3 | 4 | 7 | 3.1 | 120 |

Composite type: Al-Zr-C for working line, outer Al-C material

| Al-Zr-C & Al-C Material | ||||||

| Al2O3 | C | ZrO2 | Apparent porosity | Bulk density | C.C.S | |

| (% minm) | (% minm) | (% minm) | (% max) | (gm./cc minm) | (MPa minm) | |

| Inner side (Working face) | 85 | 3 | 4 | 7 | 3.1 | 120 |

| Outside | 90 | 3 | 0 | 9 | 3 | |

Using the raw materials of tabular alumina, zirconia-corundum, carbon and other high-grade additives, after sintering to obtain characteristics of oxidation resistance, scour strength, erosion resistance, thermal shock resistance, shape stable and long service life, made our products the preferred materials for the large and medium-sized steel ladle, refining ladle, series of alloy steel ladle, and tundish. Our high performance sintering sliding gates include alumina carbon , Al2O3-ZrO2-C, etc, can meet the needs of different steel grade.

Other Products

About us

Sample is on your request.

Welcome to visit our factory~

- Q: How do monolithic refractories withstand the corrosive environments in steelmaking processes?

- Monolithic refractories withstand corrosive environments in steelmaking processes due to their high chemical resistance and thermal stability. These refractories are made from a single, continuous material, eliminating joints and weak points that can be susceptible to corrosion. They are composed of materials such as high-alumina, silica, or magnesia, which possess excellent resistance to chemical attacks from molten metals, slags, and gases present in steelmaking. Additionally, monolithic refractories can be designed with specific additives and binders to further enhance their resistance to corrosion, ensuring their durability and prolonged service life in the harsh conditions of steelmaking processes.

- Q: How do monolithic refractories perform in aluminum holding furnace applications?

- The use of monolithic refractories in aluminum holding furnace applications has been proven to be highly efficient and effective. These refractories are designed specifically to withstand the extreme temperatures and chemical environments found in these furnaces. One major advantage of monolithic refractories is their ability to create a continuous and seamless lining in the furnace. This eliminates the need for individual bricks or tiles, reducing the risk of thermal shock and cracking. The absence of joints also minimizes the likelihood of molten aluminum leaking through the lining, ensuring better containment and heat retention. Monolithic refractories also provide excellent thermal insulation properties, which are essential in aluminum holding furnaces. They have low thermal conductivity, helping to reduce heat loss and maintain a stable temperature within the furnace. This leads to improved energy efficiency and lower operating costs. Furthermore, monolithic refractories have exceptional resistance to corrosion and chemical attack from molten aluminum and its by-products, such as dross and fluxes. This resistance ensures a longer lifespan for the refractory lining, reducing the need for maintenance and downtime. In addition, monolithic refractories are known for their easy installation and repair. They can be installed quickly and easily, requiring minimal downtime for furnace maintenance. If any localized damage or wear occurs, repairs can be efficiently made by patching or spraying the affected area. In conclusion, monolithic refractories are an excellent choice for aluminum holding furnace applications due to their seamless lining, thermal insulation properties, resistance to corrosion, and easy installation and repair. These refractories significantly enhance the overall performance and efficiency of aluminum holding furnaces.

- Q: How do monolithic refractories prevent heat loss through convection?

- Monolithic refractories effectively prevent heat loss through convection due to their unique composition and structure. Unlike traditional refractory bricks, which often have gaps and are porous, monolithic refractories are made of a single, seamless structure. This eliminates any possible pathways for hot gases or air to circulate and carry away heat by convection. Furthermore, monolithic refractories have a high thermal conductivity and are often dense, making them excellent conductors of heat. This allows them to rapidly absorb and distribute heat, minimizing the temperature difference between the hot surface and the surrounding environment. By reducing the temperature gradient, monolithic refractories decrease the driving force for convection, resulting in reduced heat loss through this mechanism. Moreover, monolithic refractories can be applied as a continuous lining, conforming to the shape of the equipment or furnace being protected. This seamless application eliminates joints or gaps where hot gases or air could escape and carry away heat. The uniform and uninterrupted lining further decreases the potential for convection heat loss. In summary, monolithic refractories are specifically designed to create a barrier that hinders the movement of hot gases or air, effectively minimizing heat loss through convection. Their dense composition, high thermal conductivity, and seamless application all contribute to their effectiveness in preventing heat loss through this mechanism.

- Q: How do monolithic refractories prevent slag penetration?

- Monolithic refractories prevent slag penetration through several mechanisms. Firstly, monolithic refractories are made up of high-quality materials that have excellent resistance to slag attack. These materials, such as alumina, silica, and magnesia, have a high melting point and can withstand the corrosive nature of the slag. Secondly, monolithic refractories are designed with a dense and compact structure that minimizes the porosity. Slag penetration occurs when the molten slag infiltrates the pores and cracks of the refractory material. By reducing the porosity, monolithic refractories create a barrier that restricts the entry of slag into the refractory lining. Additionally, monolithic refractories can be chemically bonded to the substrate, forming a strong and impermeable bond. This bond further enhances the resistance to slag penetration by preventing any gaps or weak points where the slag can penetrate. Moreover, monolithic refractories can be designed with a high thermal shock resistance. Slag penetration is often intensified by thermal cycling, where the refractory material undergoes rapid temperature changes. Monolithic refractories with high thermal shock resistance can withstand these temperature fluctuations without cracking or spalling, thus reducing the risk of slag penetration. Furthermore, the proper installation and maintenance of monolithic refractories play a crucial role in ensuring their effectiveness against slag penetration. The refractory lining needs to be properly designed, using appropriate thickness and geometry, to provide maximum protection against slag attack. Regular inspection and repair of any damaged or worn-out areas can also prevent slag penetration. In conclusion, monolithic refractories prevent slag penetration through their excellent resistance to slag attack, dense structure, chemical bonding, high thermal shock resistance, and proper installation and maintenance. These factors work together to create a strong and impermeable barrier that protects the underlying substrate from the corrosive effects of slag.

- Q: How are monolithic refractories different from traditional refractories?

- Monolithic refractories differ from traditional refractories in their composition and installation process. Unlike traditional refractories, which are made from pre-formed bricks or shapes, monolithic refractories are produced as a single, homogeneous mass. This allows for easier and faster installation, as they can be poured or gunned into place. Monolithic refractories also exhibit better thermal shock resistance, higher strength, and improved resistance to chemical attacks, making them a preferred choice in many industrial applications.

- Q: What are the key properties of monolithic refractories?

- The key properties of monolithic refractories include high strength, thermal shock resistance, erosion and abrasion resistance, good thermal conductivity, and excellent chemical resistance. These properties make monolithic refractories suitable for applications where high temperatures, harsh environments, and mechanical stresses are present, such as in furnaces, kilns, and reactors.

- Q: How are monolithic refractories different from traditional refractory bricks?

- Monolithic refractories are different from traditional refractory bricks because they are not pre-fabricated into brick shapes. Instead, they are supplied as a ready-mix or ready-to-use material that can be directly applied on-site. This eliminates the need for complex brick-laying processes and allows for a more flexible and efficient installation. Monolithic refractories also have superior thermal shock resistance and can withstand higher temperatures, making them ideal for demanding industrial applications.

- Q: Can monolithic refractories be customized for specific iron and steel processing requirements?

- Indeed, monolithic refractories possess the capability to be personalized in order to satisfy the distinct demands of iron and steel processing. Renowned for their adaptability and versatility, monolithic refractories can be tailored to accommodate a wide range of applications. The formulation, tangible characteristics, and methods of installation can all be modified to cater to the specific necessities of iron and steel processing. For instance, the selection of raw materials employed in the production of monolithic refractories can be customized to endure the formidable temperatures and harsh chemical environments inherent in iron and steel processing. Diverse types of aggregates, binders, and additives can be chosen to augment the refractory's resistance against thermal shock, erosion, and corrosion. Moreover, the installation technique for monolithic refractories can be adjusted to suit the precise requirements of iron and steel processing. Whether it is gunning, casting, ramming, or spraying, the method of installation can be personalized to guarantee optimal performance and durability in the given application. Additionally, monolithic refractories can also be tailored to particular shapes and sizes to accommodate the various equipment and structures utilized in iron and steel processing. This facilitates a more precise and efficient lining of furnaces, ladles, tundishes, and other vessels, thereby enhancing overall productivity and performance in the process. In conclusion, monolithic refractories can be customized to cater to the distinct requirements of iron and steel processing by modifying their composition, tangible characteristics, installation techniques, and shape. This customization ensures that the refractories can withstand the extreme conditions encountered in these industries, resulting in improved performance, prolonged service life, and enhanced productivity.

- Q: What are the main factors affecting the abrasion resistance of monolithic refractories?

- There are three key aspects that categorize the main factors influencing the abrasion resistance of monolithic refractories: material composition, microstructure, and service conditions. Firstly, the abrasion resistance of monolithic refractories is significantly determined by their material composition. The selection of raw materials, such as aggregates and binders, directly impacts the overall hardness, strength, and wear resistance of the refractories. For example, high-alumina refractories, which have a high proportion of alumina as their main component, demonstrate exceptional abrasion resistance due to the hardness and toughness of alumina. Conversely, refractories with a higher percentage of softer materials like clay or magnesia may exhibit lower abrasion resistance. Secondly, the microstructure of monolithic refractories plays a crucial role in their ability to endure abrasion. The arrangement and orientation of the aggregates, as well as the bond strength between the particles and the matrix, significantly contribute to their resistance against wear. An evenly distributed and interconnected network of aggregates can strengthen the refractories and enhance their resistance to abrasion. Additionally, a compact and well-sintered matrix can prevent abrasive particles from penetrating, thereby reducing wear. Lastly, the service conditions under which monolithic refractories operate are vital factors in determining their abrasion resistance. Variables such as temperature, atmosphere, and mechanical stress can greatly impact the wear behavior of refractories. High temperatures can cause thermal expansion and contraction, resulting in cracks and spalling, which accelerate abrasion. The presence of corrosive gases or chemicals can also deteriorate the microstructure of refractories, diminishing their wear resistance. Moreover, mechanical stress from impact or friction can lead to localized wear and damage the refractories. To conclude, the abrasion resistance of monolithic refractories is influenced by material composition, microstructure, and service conditions. By carefully selecting suitable raw materials, optimizing the microstructure, and considering specific service conditions, it is possible to enhance the abrasion resistance of monolithic refractories and improve their overall performance in high-wear applications.

- Q: What are the considerations for selecting monolithic refractories for reheating furnaces?

- There are several key considerations when selecting monolithic refractories for reheating furnaces. Firstly, the refractory material must have excellent thermal conductivity to efficiently transfer heat to the steel being reheated. Additionally, it should possess high resistance to thermal shock and mechanical stress to withstand the rapid temperature changes and mechanical forces experienced in the furnace. The refractory should also have low porosity to prevent the penetration of gases and slag, ensuring a longer service life. Other factors to consider include the refractory's resistance to corrosive environments, ease of installation, and cost-effectiveness. Ultimately, choosing the right monolithic refractory is crucial to ensure optimal furnace performance and longevity.

Send your message to us

Monolithic Refractories High Temperature Ladle Sliding Gate for Iron and Steel Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords