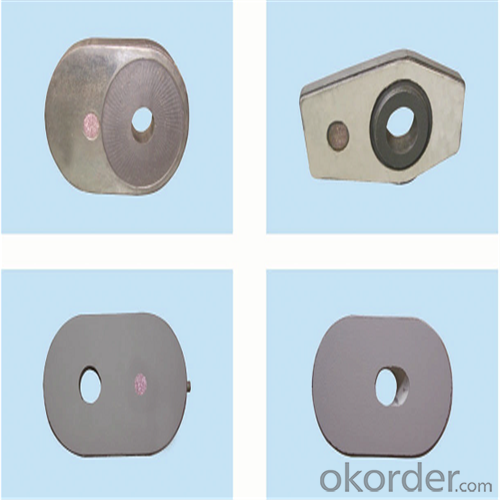

Monolithic Refractories High Performance & Temperature Ladle Sliding Gate for Iron and Steel Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for High Performance Refractory Ladle Slide Gate

| Place of Origin: | China (Mainland) | Shape: | Plate | Material: | Alumina Block |

| SiO2 Content (%): | N/A | Al2O3 Content (%): | 80-90% | MgO Content (%): | N/A |

| CaO Content (%): | N/A | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | N/A |

| SiC Content (%): | N/A | Model Number: | CS80 | Brand Name: | |

| Product name: | High performance refractory ladle slide gate | Model No.: | cs80 | Brand name: | CMAX |

| Quality: | Al-C or Al-Zr-C | Service life: | 4-6 heats | Apparent porosity: | 7% Max |

| Bulk density:: | 3.1 MIN | C.C.S: | 120MPA | MOQ: | 100 pcs for trial |

| Delivery time: | 60 working days upon receipt of deposit |

Packaging & Delivery

| Packaging Details: | Inner carton packing, outer wooden case suitable for long term sea shipping |

| Delivery Detail: | three months working days upon receipt of deposit |

Specifications

Surface flatness less than 0.05mm

High mechanical strength

Erosion resistance

Oxidation resistance

Thermal shock stability

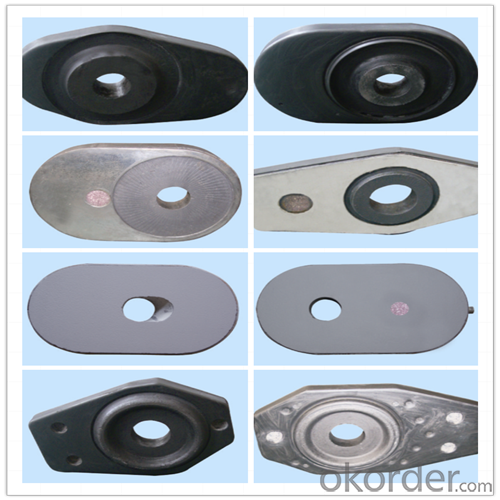

Using the raw materials of tabular alumina, zirconia-corundum, carbon and other high-grade additives, after sintering to obtain characteristics of oxidation resistance, scour strength, erosion resistance, thermal shock resistance, shape stable and long service life, made our products the preferred materials for the large and medium-sized steel ladle, refining ladle, series of alloy steel ladle, and tundish. Our high performance sintering sliding gates include alumina carbon , Al2O3-ZrO2-C, etc, can meet the needs of different steel grade.

General Chemical Analysis for refractory ladle slide gate :

slide gate plate widely including Alumina carbon and Alumina Zirconia Carbon slide gate plate, MgO and MgO-spinel slide gate plate,nonoxides bonding slide gate plateand unburned slide gate plate.

Alumina -Zirconia-Carbon material

| Al-Zr-C Material | |||||

| Al2O3 | C | ZrO2 | Apparent porosity | Bulk density | C.C.S |

| (% minm) | (% minm) | (% minm) | (% max) | (gm./cc minm) | (MPa minm) |

| 85 | 3 | 5 | 7 | 3.1 | 120 |

| 85 | 3 | 4 | 7 | 3.1 | 120 |

Composite type: Al-Zr-C for working line, outer Al-C material

| Al-Zr-C & Al-C Material | ||||||

| Al2O3 | C | ZrO2 | Apparent porosity | Bulk density | C.C.S | |

| (% minm) | (% minm) | (% minm) | (% max) | (gm./cc minm) | (MPa minm) | |

| Inner side (Working face) | 85 | 3 | 4 | 7 | 3.1 | 120 |

| Outside | 90 | 3 | 0 | 9 | 3 | |

Other Products

About us

Welcome to visit our factory~

- Q: How do monolithic refractories impact the quality of iron and steel products?

- Monolithic refractories play a crucial role in influencing the quality of iron and steel products. These refractories are widely used in the lining of furnaces and other high-temperature environments where iron and steel are processed. Firstly, monolithic refractories provide insulation and protect the lining of the furnace from the extreme heat generated during the iron and steel manufacturing process. By maintaining the desired temperature, these refractories ensure the proper and consistent heating of the metal, which is essential for achieving the desired product quality. Without adequate insulation, the heat loss would be significant, leading to inefficient energy consumption and inconsistent product quality. Secondly, monolithic refractories have a significant impact on the overall cleanliness of the iron and steel. During the production process, impurities and slag are formed, which can contaminate the metal if not properly managed. Refractories with high resistance to slag penetration and corrosion prevent these impurities from infiltrating the metal, ensuring a cleaner and purer final product. Furthermore, monolithic refractories also contribute to the mechanical strength and durability of the furnace lining. The lining needs to withstand the harsh conditions and repeated thermal shocks encountered during the iron and steel production process. A strong and well-designed refractory lining can resist cracking, spalling, and erosion, extending the life of the furnace and minimizing the risk of downtime. In conclusion, monolithic refractories have a profound impact on the quality of iron and steel products. They provide thermal insulation, prevent contamination, and ensure the mechanical integrity of the furnace lining. By choosing the appropriate refractory material and maintaining it properly, manufacturers can optimize their production processes, increase product quality, and enhance overall operational efficiency.

- Q: How do monolithic refractories improve the lining of converters and refining vessels?

- Improving the lining of converters and refining vessels is a crucial role played by monolithic refractories in several ways. To begin with, these refractories offer exceptional thermal insulation properties, which effectively maintain the desired temperature within the converters and refining vessels. This is particularly important as the metallurgical processes require high temperatures to be effective. Furthermore, the high chemical resistance of monolithic refractories is vital in the harsh conditions of converters and refining vessels. These vessels often come into contact with corrosive materials and aggressive slags, but the monolithic refractories prevent any deterioration or erosion of the lining caused by these substances. In addition, the mechanical strength and stability provided by monolithic refractories ensure that the lining remains intact even under high operational stresses. This is especially significant in converters and refining vessels where frequent mechanical movements and thermal expansions occur. Moreover, monolithic refractories offer easy installation and repair compared to traditional bricks, which require complex and time-consuming assembling. Monolithic refractories can be applied as a single mass, minimizing downtime during installation or repair. This results in time and cost savings for maintaining the lining of converters and refining vessels. Overall, the utilization of monolithic refractories significantly enhances the performance and longevity of converters and refining vessels. Their excellent thermal insulation, chemical resistance, mechanical strength, and ease of installation and repair guarantee efficient and reliable operation in metallurgical processes.

- Q: What are the key characteristics of monolithic refractories for electric arc furnace applications?

- The key characteristics of monolithic refractories for electric arc furnace applications include excellent thermal shock resistance, high erosion and corrosion resistance, good mechanical strength, and the ability to withstand high temperatures and aggressive chemical environments. Monolithic refractories also offer easy installation and maintenance due to their shape versatility and ability to be cast or gunned into place, ensuring optimal performance and longevity in electric arc furnace operations.

- Q: What are the key differences between acidic and basic monolithic refractories?

- The key differences between acidic and basic monolithic refractories lie in their chemical compositions and their behavior in different environments. Acidic monolithic refractories are primarily composed of acidic oxides such as silica (SiO2) or alumina (Al2O3). These materials have a high resistance to acidic environments and are commonly used in industries where they come into contact with acidic gases or liquids. Acidic refractories are characterized by their ability to withstand high temperatures and resist chemical erosion. They are generally not suitable for use in basic or alkaline conditions, as they can react with basic compounds and lose their effectiveness. On the other hand, basic monolithic refractories are composed of basic oxides such as magnesia (MgO) or dolomite (MgO-CaO). These materials have a high resistance to basic or alkaline environments and are commonly used in industries where they come into contact with basic compounds such as lime or cement. Basic refractories are characterized by their ability to withstand high temperatures and resist chemical erosion from basic compounds. They are generally not suitable for use in acidic conditions, as they can react with acidic compounds and lose their effectiveness. In terms of their physical properties, acidic monolithic refractories tend to have higher melting points and better thermal shock resistance compared to basic monolithic refractories. This is due to the higher melting points of acidic oxides and their ability to form stable silicate or aluminate structures at high temperatures. On the other hand, basic monolithic refractories generally have higher density and better resistance to penetration by molten materials. In conclusion, the key differences between acidic and basic monolithic refractories lie in their chemical compositions and their behavior in different environments. Acidic refractories are suitable for acidic conditions, have higher melting points, and better thermal shock resistance, while basic refractories are suitable for basic conditions, have higher density, and better resistance to penetration by molten materials.

- Q: How do monolithic refractories enhance the performance of ladle and tundish preheating systems?

- There are several ways in which monolithic refractories play a crucial role in improving the performance of ladle and tundish preheating systems. To begin with, monolithic refractories possess outstanding thermal insulation properties, which aid in retaining heat within the ladle and tundish preheating systems. This insulation ability reduces heat loss and ensures that the preheating systems operate at optimal temperatures. By maintaining a consistent and high heat level, monolithic refractories enable efficient preheating of ladles and tundishes, thereby reducing the time required for the preheating process. Furthermore, monolithic refractories exhibit high refractoriness, enabling them to withstand extreme temperatures without significant degradation. This is especially important for ladle and tundish preheating systems that endure intense heat during operation. The capacity of monolithic refractories to withstand high temperatures ensures their longevity and prevents premature failure, resulting in enhanced performance and reliability of the preheating systems. Moreover, monolithic refractories possess exceptional resistance to thermal shock. The preheating process often subjects ladles and tundishes to rapid temperature changes, which can cause thermal stress and lead to cracking and spalling of the refractory lining. However, monolithic refractories, with their superior resistance to thermal shock, can endure these rapid temperature fluctuations without sustaining significant damage. This resistance guarantees the integrity of the refractory lining, extending the lifespan of the ladle and tundish preheating systems and improving their overall performance. Additionally, monolithic refractories offer good mechanical strength and abrasion resistance. Ladles and tundishes frequently experience mechanical forces, such as stirring and pouring of molten metal. The presence of monolithic refractories with high mechanical strength and abrasion resistance ensures the integrity of the refractory lining even under harsh conditions. This durability allows for prolonged and efficient operation of the preheating systems, contributing to their enhanced performance. In conclusion, monolithic refractories enhance the performance of ladle and tundish preheating systems through their excellent thermal insulation, high refractoriness, resistance to thermal shock, and good mechanical strength and abrasion resistance. These properties enable efficient and reliable preheating, minimize heat loss, prevent premature failure, and prolong the lifespan of the preheating systems, ultimately improving their overall performance.

- Q: How do monolithic refractories improve the thermal efficiency of iron and steel furnaces?

- Monolithic refractories improve the thermal efficiency of iron and steel furnaces by providing superior insulation and heat containment properties. These refractories are designed to withstand extreme temperatures and resist thermal shock, ensuring minimal heat loss from the furnace. Additionally, monolithic refractories have low thermal conductivity, allowing for better heat distribution and retention within the furnace. This enhanced thermal efficiency leads to reduced energy consumption and higher productivity in the iron and steel manufacturing process.

- Q: How do monolithic refractories resist corrosion and erosion in iron and steel applications?

- Monolithic refractories, unlike traditional refractory bricks, consist of a single, homogeneous material and are highly resilient and effective in combating corrosion and erosion in iron and steel applications. Their monolithic nature provides several advantages when it comes to corrosion and erosion resistance. One key advantage is their low porosity, which prevents corrosive agents like molten metal or slag from infiltrating the refractory structure. By minimizing interconnected pores, monolithic refractories significantly reduce the likelihood of chemical reactions that cause corrosion. Moreover, monolithic refractories exhibit excellent resistance to thermal shock, a common issue in iron and steel applications due to rapid temperature changes. Their high thermal conductivity and low thermal expansion enable them to withstand thermal shock without compromising their integrity. This characteristic allows them to resist erosion caused by the flow of molten metal or slag. Additionally, monolithic refractories are highly durable and possess good mechanical strength, enabling them to withstand the abrasive forces often encountered in iron and steel applications. The intense mechanical impact, vibrations, and abrasive wear experienced in these environments can be effectively resisted by monolithic refractories, ensuring their longevity and reliability. In conclusion, monolithic refractories are the preferred choice for lining furnaces, ladles, and other equipment used in the production of iron and steel due to their resistance to corrosion and erosion. Their low porosity, excellent resistance to thermal shock, and high mechanical strength make them an ideal option for these demanding applications.

- Q: How do monolithic refractories improve the performance of iron and steel furnaces?

- Monolithic refractories, unlike traditional brick-based refractories, offer several advantages that enhance the performance of iron and steel furnaces. Firstly, their seamless design eliminates joints and seams, reducing the risk of thermal shock and leakage, leading to improved insulation and energy efficiency. Additionally, monolithic refractories have higher thermal conductivity and superior resistance to chemical attacks, ensuring longer furnace life and reduced maintenance costs. Their ability to be easily shaped and installed also allows for better lining optimization, promoting better heat transfer and uniform temperature distribution within the furnace. Ultimately, monolithic refractories contribute to increased productivity, reduced downtime, and overall improved performance of iron and steel furnaces.

- Q: How do monolithic refractories improve energy efficiency in the iron and steel industry?

- Monolithic refractories improve energy efficiency in the iron and steel industry by providing better insulation and reducing heat loss. They have lower thermal conductivity compared to traditional refractory bricks, which means less heat is conducted through the lining of the furnaces or kilns. This leads to reduced energy consumption and improved thermal efficiency. Additionally, monolithic refractories offer better resistance to thermal shock, minimizing the need for frequent repairs or replacements, thereby saving energy and reducing downtime.

- Q: What are the common challenges faced by monolithic refractories in the iron and steel industry?

- The iron and steel industry heavily relies on monolithic refractories, which have a vital role in various applications like lining furnaces, ladles, and tundishes. However, these materials encounter common challenges in this industry. Thermal shock is a major challenge. Monolithic refractories undergo extreme temperature changes, especially during start-up and shut-down phases. This rapid heating and cooling can cause thermal stress, leading to cracking and spalling. To combat this, refractory manufacturers create high-quality monolithic materials with enhanced thermal shock resistance. Corrosion is another significant challenge. The iron and steel industry exposes refractory linings to aggressive materials like molten metal, slag, and gases, which chemically attack them. This corrosion results in material degradation, erosion, and reduced service life. To address this, specialized monolithic refractories with excellent corrosion resistance are used, often containing additives that can withstand the corrosive environment. Abrasion is also a common challenge faced by monolithic refractories in this industry. The movement of raw materials, molten metal, and slag causes mechanical wear on the refractory lining, leading to material loss and compromised performance. Refractory manufacturers develop abrasion-resistant monolithic materials that can withstand intense wear and tear, ensuring extended service life. Moreover, good thermal conductivity is often required in the iron and steel industry. This is crucial for efficient heat transfer and maintaining optimal operating conditions. Achieving the right balance between thermal conductivity and mechanical strength can be challenging, as refractories with high thermal conductivity often have lower mechanical strength. Therefore, selecting the appropriate monolithic refractory with desired thermal conductivity properties is crucial for optimal performance. Lastly, installation and maintenance present challenges for monolithic refractories. The application of these refractories requires skilled personnel and careful installation techniques due to their liquid or semi-liquid nature. Additionally, regular maintenance and repairs are necessary to ensure the refractory lining's longevity and performance. Regular inspections, repairs, and proper curing techniques are vital to mitigate these challenges and optimize refractory performance. In conclusion, monolithic refractories in the iron and steel industry face challenges such as thermal shock, corrosion, abrasion, thermal conductivity, and installation/maintenance. Addressing these challenges through the development of specialized refractory materials and employing proper installation and maintenance techniques are crucial for ensuring efficient and reliable performance in this demanding industry.

Send your message to us

Monolithic Refractories High Performance & Temperature Ladle Sliding Gate for Iron and Steel Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords