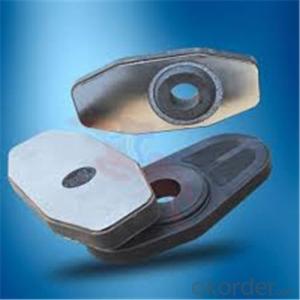

Monolithic Refractories High Temperature Ladle Sliding Gate for Iron and Steel Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for High Performance Refractory Ladle Slide Gate

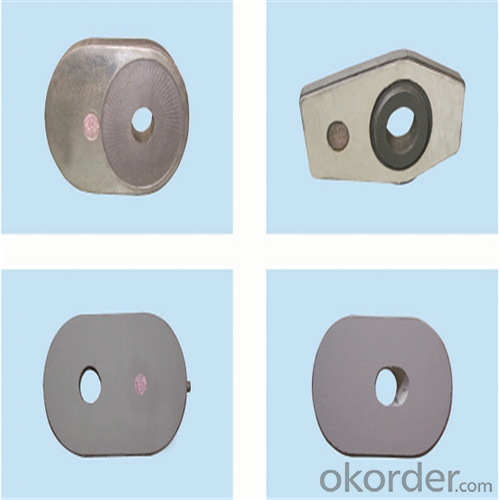

| Place of Origin: | China (Mainland) | Shape: | Plate | Material: | Alumina Block |

| SiO2 Content (%): | N/A | Al2O3 Content (%): | 80-90% | MgO Content (%): | N/A |

| CaO Content (%): | N/A | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | N/A |

| SiC Content (%): | N/A | Model Number: | CS80 | Brand Name: | |

| Product name: | High performance refractory ladle slide gate | Model No.: | cs80 | Brand name: | CMAX |

| Quality: | Al-C or Al-Zr-C | Service life: | 4-6 heats | Apparent porosity: | 7% Max |

| Bulk density:: | 3.1 MIN | C.C.S: | 120MPA | MOQ: | 100 pcs for trial |

| Delivery time: | 60 working days upon receipt of deposit |

Packaging & Delivery

| Packaging Details: | Inner carton packing, outer wooden case suitable for long term sea shipping |

| Delivery Detail: | three months working days upon receipt of deposit |

Specifications

Surface flatness less than 0.05mm

High mechanical strength

Erosion resistance

Oxidation resistance

Thermal shock stability

General Chemical Analysis for refractory ladle slide gate :

slide gate plate widely including Alumina carbon and Alumina Zirconia Carbon slide gate plate, MgO and MgO-spinel slide gate plate,nonoxides bonding slide gate plateand unburned slide gate plate.

Alumina -Zirconia-Carbon material

| Al-Zr-C Material | |||||

| Al2O3 | C | ZrO2 | Apparent porosity | Bulk density | C.C.S |

| (% minm) | (% minm) | (% minm) | (% max) | (gm./cc minm) | (MPa minm) |

| 85 | 3 | 5 | 7 | 3.1 | 120 |

| 85 | 3 | 4 | 7 | 3.1 | 120 |

Composite type: Al-Zr-C for working line, outer Al-C material

| Al-Zr-C & Al-C Material | ||||||

| Al2O3 | C | ZrO2 | Apparent porosity | Bulk density | C.C.S | |

| (% minm) | (% minm) | (% minm) | (% max) | (gm./cc minm) | (MPa minm) | |

| Inner side (Working face) | 85 | 3 | 4 | 7 | 3.1 | 120 |

| Outside | 90 | 3 | 0 | 9 | 3 | |

Using the raw materials of tabular alumina, zirconia-corundum, carbon and other high-grade additives, after sintering to obtain characteristics of oxidation resistance, scour strength, erosion resistance, thermal shock resistance, shape stable and long service life, made our products the preferred materials for the large and medium-sized steel ladle, refining ladle, series of alloy steel ladle, and tundish. Our high performance sintering sliding gates include alumina carbon , Al2O3-ZrO2-C, etc, can meet the needs of different steel grade.

Other Products

About us

Welcome to visit our factory~

- Q: How are monolithic refractories different from traditional brick refractories?

- Monolithic refractories differ from traditional brick refractories in several ways. Firstly, monolithic refractories are made from a single, homogeneous material, while traditional brick refractories are made from individual bricks that are assembled together. This difference in construction allows monolithic refractories to have a more uniform and consistent structure, which can enhance their performance and durability. Secondly, monolithic refractories are typically easier to install compared to traditional brick refractories. Since they are made from a single material, they can be poured or sprayed into place, eliminating the need for precise bricklaying and mortar application. This ease of installation saves time and labor during construction or repair projects. Additionally, monolithic refractories often have superior thermal shock resistance compared to traditional brick refractories. The homogeneous structure of monolithic refractories allows them to expand and contract more uniformly under thermal stress, reducing the risk of cracking and failure. This makes monolithic refractories more suitable for applications where rapid temperature changes occur, such as in furnaces or kilns. Furthermore, monolithic refractories can offer better resistance to chemical attacks and erosion. Traditional brick refractories may have joints and gaps between bricks, which can become vulnerable to chemical reactions or erosion over time. Monolithic refractories, on the other hand, have a seamless structure that minimizes the risk of chemical penetration and erosion, enhancing their longevity and performance. Overall, monolithic refractories offer advantages in terms of uniformity, ease of installation, thermal shock resistance, and chemical resistance compared to traditional brick refractories. These differences make monolithic refractories a preferred choice for many industrial applications where high temperatures and harsh environments are present.

- Q: What are the key trends in the use of monolithic refractories in the iron and steel industry?

- It is worth noting that there are several notable trends in the use of monolithic refractories in the iron and steel industry. First and foremost, there is an increasing demand for monolithic refractories due to their superior performance characteristics in comparison to traditional brick refractories. Monolithic refractories provide higher thermal shock resistance, superior insulation properties, and improved resistance to chemical attacks. As a result, they are being used more extensively in various applications within the iron and steel industry. Secondly, there is a shift towards the utilization of low-cement and ultra-low cement castables in monolithic refractories. These materials contain a reduced amount of cement, leading to enhanced refractory properties such as increased strength, better corrosion resistance, and improved resistance to thermal spalling. This trend is driven by the need to enhance the overall efficiency and longevity of refractory linings in iron and steel manufacturing processes. Another significant trend is the development of advanced monolithic refractories that prioritize sustainability and environmental performance. The iron and steel industry is facing mounting pressure to reduce its carbon footprint and minimize its impact on the environment. Consequently, there is a growing emphasis on the use of environmentally friendly binders and additives in monolithic refractories. These novel materials not only offer excellent refractory properties but also contribute to the industry's sustainability objectives. Moreover, there is an increasing focus on the development of monolithic refractories capable of withstanding extreme operating conditions. Iron and steel manufacturing processes involve high temperatures, aggressive chemical environments, and severe mechanical stresses. Consequently, there is a need for monolithic refractories that can withstand these harsh conditions without compromising their performance. The industry is investing in research and development to create refractories that exhibit exceptional resistance to thermal shock, abrasion, and erosion. Lastly, there is a growing adoption of digital and smart technologies for the monitoring and maintenance of monolithic refractories. Advances in sensor technology and data analytics have made it possible to collect real-time data on the condition and performance of refractory linings. This enables proactive maintenance, early detection of potential issues, and optimization of refractory usage, ultimately leading to improved operational efficiency and cost savings. In conclusion, the use of monolithic refractories in the iron and steel industry is witnessing key trends such as the demand for superior performance, the shift towards low-cement and ultra-low cement castables, the development of sustainable materials, the focus on extreme operating conditions, and the adoption of digital and smart technologies for monitoring and maintenance. These trends reflect the industry's continuous efforts to enhance the efficiency, durability, and environmental sustainability of refractory linings in iron and steel manufacturing processes.

- Q: What are the advantages of using insulating castables in the iron and steel industry?

- The advantages of using insulating castables in the iron and steel industry are numerous. Firstly, insulating castables have excellent thermal insulation properties, which help to reduce heat loss during the manufacturing process. This leads to increased energy efficiency and cost savings for the industry. Additionally, insulating castables have a low thermal conductivity, meaning they can withstand high temperatures without transferring excessive heat. This is crucial in the iron and steel industry, where temperatures can reach extremely high levels. By using insulating castables, the industry can ensure the longevity and durability of its equipment and structures. Furthermore, insulating castables have good resistance to thermal shock, meaning they can withstand rapid temperature changes without cracking or breaking. This is particularly beneficial in the iron and steel industry, where the heating and cooling processes are frequent and intense. Lastly, insulating castables have a low density, making them lightweight and easier to handle and install. This not only saves time and effort during installation but also reduces the structural load on equipment and structures. Overall, the use of insulating castables in the iron and steel industry offers advantages such as improved energy efficiency, enhanced durability, resistance to thermal shock, and ease of installation.

- Q: How do monolithic refractories contribute to the overall safety of iron and steel operations?

- Monolithic refractories play a crucial role in ensuring the overall safety of iron and steel operations by providing several important benefits. Firstly, monolithic refractories are known for their high thermal insulation properties, which means they can effectively withstand extreme temperatures and prevent heat loss. This is particularly important in iron and steel operations, where high temperatures are involved in various processes such as melting, casting, and heat treatment. By minimizing heat loss, monolithic refractories help in maintaining a stable temperature environment, reducing the risk of accidents and ensuring the safety of personnel. Secondly, monolithic refractories offer excellent resistance to chemical attacks. In iron and steel operations, various chemicals and gases are present that can corrode and deteriorate the lining of furnaces, ladles, and other equipment. By providing a protective barrier, monolithic refractories prevent the penetration of these corrosive substances, thus extending the lifespan of the equipment and reducing the likelihood of failures or leaks that could pose safety hazards. Additionally, monolithic refractories are known for their structural integrity and high mechanical strength. In iron and steel operations, heavy loads and stresses are common, especially during the handling and movement of molten metal and raw materials. Monolithic refractories can withstand these stresses without cracking or collapsing, ensuring the structural stability of the equipment and minimizing the risk of accidents or equipment failure. Furthermore, monolithic refractories offer excellent thermal shock resistance. During iron and steel operations, sudden temperature changes can occur due to the introduction of cold materials or liquids into hot equipment. This thermal shock can cause cracking and spalling of the refractory lining, which can compromise the safety and efficiency of the operation. Monolithic refractories, with their ability to withstand thermal shock, help in minimizing the risk of unexpected failures and maintaining the overall safety of the operation. In conclusion, monolithic refractories contribute significantly to the overall safety of iron and steel operations by providing high thermal insulation, chemical resistance, structural integrity, and thermal shock resistance. By ensuring a stable temperature environment, protecting against chemical attacks, withstanding heavy loads, and resisting thermal shock, monolithic refractories help in preventing accidents, equipment failures, and potential hazards, thus creating a safer working environment for personnel in the iron and steel industry.

- Q: How do monolithic refractories prevent slag penetration?

- Monolithic refractories prevent slag penetration through several mechanisms. Firstly, monolithic refractories are made up of high-quality materials that have excellent resistance to slag attack. These materials, such as alumina, silica, and magnesia, have a high melting point and can withstand the corrosive nature of the slag. Secondly, monolithic refractories are designed with a dense and compact structure that minimizes the porosity. Slag penetration occurs when the molten slag infiltrates the pores and cracks of the refractory material. By reducing the porosity, monolithic refractories create a barrier that restricts the entry of slag into the refractory lining. Additionally, monolithic refractories can be chemically bonded to the substrate, forming a strong and impermeable bond. This bond further enhances the resistance to slag penetration by preventing any gaps or weak points where the slag can penetrate. Moreover, monolithic refractories can be designed with a high thermal shock resistance. Slag penetration is often intensified by thermal cycling, where the refractory material undergoes rapid temperature changes. Monolithic refractories with high thermal shock resistance can withstand these temperature fluctuations without cracking or spalling, thus reducing the risk of slag penetration. Furthermore, the proper installation and maintenance of monolithic refractories play a crucial role in ensuring their effectiveness against slag penetration. The refractory lining needs to be properly designed, using appropriate thickness and geometry, to provide maximum protection against slag attack. Regular inspection and repair of any damaged or worn-out areas can also prevent slag penetration. In conclusion, monolithic refractories prevent slag penetration through their excellent resistance to slag attack, dense structure, chemical bonding, high thermal shock resistance, and proper installation and maintenance. These factors work together to create a strong and impermeable barrier that protects the underlying substrate from the corrosive effects of slag.

- Q: How do monolithic refractories contribute to the overall efficiency of steel ladle operations?

- The overall efficiency of steel ladle operations can be greatly improved by the use of monolithic refractories. These refractories, which are engineered materials installed as a single structure within the ladle, offer numerous advantages that directly contribute to operational efficiency. One key benefit of monolithic refractories is their exceptional thermal insulation properties. They have a low thermal conductivity, meaning they are effective at retaining and containing heat within the ladle. This insulation helps to maintain the desired temperature of the molten steel, preventing heat loss during transportation and reducing the need for frequent reheating. By minimizing heat loss, monolithic refractories enable a more efficient use of energy resources, resulting in cost savings and improved productivity. Moreover, monolithic refractories possess a high refractoriness, meaning they can withstand high temperatures without losing their structural integrity. This is crucial in steel ladle operations, where extreme temperatures are encountered during the steelmaking process. The high refractoriness of monolithic refractories ensures that they can withstand the intense heat and avoid any damage or failure of the ladle lining. This durability translates into reduced downtime and maintenance requirements, leading to increased operational efficiency. Additionally, monolithic refractories offer excellent resistance to chemical attack. The ladles used in steelmaking come into contact with various corrosive substances, such as molten metals, slag, and fluxes. The chemical resistance of monolithic refractories prevents them from reacting with these substances, ensuring the integrity and longevity of the ladle lining. This resistance to chemical attack reduces the need for repairs and replacements, minimizing downtime and improving overall operational efficiency. Furthermore, the installation of monolithic refractories is relatively quick and straightforward compared to traditional brick linings. This ease of installation saves time and labor costs, allowing for a faster turnaround between ladle operations. It enables steel manufacturers to optimize their production schedules and enhance overall operational efficiency. In conclusion, monolithic refractories play a significant role in improving the efficiency of steel ladle operations. Their thermal insulation properties, high refractoriness, resistance to chemical attack, and ease of installation all contribute to enhanced energy efficiency, reduced downtime, and increased productivity. By choosing to use monolithic refractories, steel manufacturers can achieve optimized ladle performance and ultimately improve their steelmaking process as a whole.

- Q: What are the key innovations in monolithic refractories for the iron and steel industry?

- Some key innovations in monolithic refractories for the iron and steel industry include the development of advanced materials such as low cement castables, gunning mixes, and shotcretes. These materials offer improved resistance to thermal shock, increased strength, and enhanced erosion resistance, thereby extending the service life of refractory linings in high-temperature environments. Additionally, the introduction of monolithic refractory installation techniques such as robotic application and advanced spraying technologies has improved efficiency and reduced downtime during maintenance and repair operations.

- Q: How are monolithic refractories different from traditional refractory bricks?

- Monolithic refractories, unlike traditional refractory bricks, are composed of a single, homogeneous structure. This structural distinction leads to several differences between the two. Firstly, monolithic refractories provide greater flexibility and versatility in terms of shape and installation. They can be easily molded and shaped to fit specific applications and complex geometries, making them ideal for lining furnaces, kilns, and other high-temperature equipment. Secondly, monolithic refractories have superior thermal shock resistance compared to traditional refractory bricks. Their uniform structure allows for better heat distribution, minimizing the risk of thermal stress and cracking. This makes them suitable for applications with rapid temperature fluctuations or severe thermal cycling. Additionally, monolithic refractories often exhibit better overall performance in terms of strength, mechanical properties, and resistance to chemical attack. The absence of joints and seams eliminates potential weak points, resulting in a more durable and reliable lining. Moreover, the homogeneous structure provides better resistance to corrosive agents, ensuring prolonged service life in harsh environments. Lastly, monolithic refractories offer advantages in terms of installation and maintenance. Their monolithic nature simplifies the installation process, reducing labor and time requirements. Additionally, repairs and maintenance can be carried out more easily and cost-effectively compared to traditional refractory bricks, which may require the replacement of entire sections or bricks. In summary, monolithic refractories differ from traditional refractory bricks in structure, flexibility, thermal shock resistance, performance, and installation characteristics. These differences make monolithic refractories a preferred choice in many high-temperature applications, offering improved efficiency, durability, and ease of use.

- Q: How do monolithic refractories prevent heat loss through radiation?

- Monolithic refractories prevent heat loss through radiation by forming a continuous and seamless layer that acts as a barrier to thermal radiation. This layer reflects and absorbs the radiant heat, preventing it from escaping and thus minimizing heat loss. Additionally, the high thermal conductivity of monolithic refractories allows them to efficiently conduct and distribute heat, further reducing the potential for radiation heat loss.

- Q: How does the choice of monolithic refractory impact the overall cost of iron and steel production?

- The overall cost of iron and steel production can be greatly affected by the choice of monolithic refractory. Monolithic refractory, unlike traditional brick or tile refractories, refers to a type of refractory material that is installed continuously. One important factor that impacts the cost of iron and steel production is the lifespan of the refractory. Monolithic refractories generally have a longer lifespan compared to traditional brick or tile refractories. This means that they require less frequent maintenance and replacement, resulting in lower overall costs over time. Additionally, monolithic refractories have a higher resistance to thermal shock and mechanical stress, which further extends their lifespan and reduces the need for repairs and replacements. Another crucial consideration is the energy efficiency of the monolithic refractory. These refractories possess better insulation properties, leading to reduced heat loss during the iron and steel production process. This helps lower energy consumption and, consequently, the overall cost of production. The improved insulation also contributes to a more stable and controlled temperature profile within the furnace, resulting in better product quality and reduced scrap rates. Furthermore, monolithic refractories offer greater flexibility in terms of installation and repair. They can be easily applied to complex shapes and structures, allowing for more efficient use of refractory materials. This reduces waste and lowers material costs. The ease of installation also saves time and labor, further contributing to cost savings. Additionally, monolithic refractories are known for their superior performance in high-temperature environments. They exhibit excellent thermal conductivity and resistance to chemical attacks, ensuring optimal furnace operation and reducing the likelihood of downtime and production delays. This, in turn, minimizes the impact of unexpected maintenance, repairs, and shutdowns on the overall cost of iron and steel production. In conclusion, the choice of monolithic refractory has a significant impact on the overall cost of iron and steel production. Its longer lifespan, improved energy efficiency, ease of installation and repair, and superior performance in high-temperature environments all contribute to cost savings in various aspects of the production process. Thus, careful consideration of the type of monolithic refractory used can result in significant cost reductions and improved overall efficiency in iron and steel production.

Send your message to us

Monolithic Refractories High Temperature Ladle Sliding Gate for Iron and Steel Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords