JIS G3461(Carbon Steel Tubes For Boiler And Heat Exchanger)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50mt m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of JIS G 3461 / JISG3461 seamless steel pipes

Scope of JIS G 3461 / JISG3461 seamless steel pipes This Japanese Industrial Standard specifies the carbon steel tubes, hereinafter refered to as the "tubes", used for excahnging heat on the inside and outside of the tube, such as water tubes, smoke tubes, superheater tubes, air preheater tubes, etc. of the boiler, ater tubes, etc. of the boiler, and heat exchanger tubes, condenser tubes, catalyser tubes, etc. used in chemical and petroleum inudstries. however, it is not applicable to the steel tubes for heating furnace and steel heat exchager tubes for bes for low temperature service. |

Classes and Symbols of JIS G 3461 / JISG3461 seamless steel pipes

The tube shall be classified into 3 grades and their class symbols shall be

as given in Table 1

Chemical Composition

(Applicable till the end of 1990)

Grade | Mfg. Process | Chemical composition(%) | ||||

C | Si | Mn | PP | |||

STB35 | S, E | 0.18Max | 0.35Max | 0.30~0.60 | 0.035Max | 0.035Max |

STB42 | S, E | 0.32Max | 0.35Max | 0.30~0.60 | 0.035Max&l"center">0.035Max | 0.035Max |

STB52 | S, E | 0.25Max | 0.35Max | 1.00~1.50 | 0.035Max | 0.035Max |

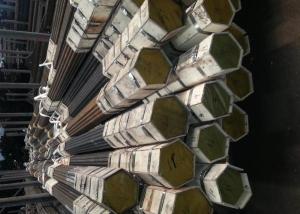

Packing of JIS G 3461 / JISG3461 seamless steel pipes

Each bundles pipes will be bundle with 8 pcs steel strips, nesting package.

- Q: How are steel pipes used in the construction of desalination plants?

- Steel pipes are commonly used in the construction of desalination plants for various purposes. They are used to transport water from the intake point to the plant, as well as to distribute the treated water to the storage tanks or other destinations. Steel pipes are also employed in the plant's infrastructure, such as for the installation of pumps, valves, and other equipment. Additionally, steel pipes are utilized for the discharge of brine, which is the concentrated salt solution generated during the desalination process. Overall, steel pipes play a crucial role in ensuring the efficient and reliable operation of desalination plants.

- Q: Can steel pipes be used in plumbing systems?

- Yes, steel pipes can be used in plumbing systems. Steel pipes have been traditionally used in plumbing systems for their durability, strength, and resistance to corrosion. However, other materials like copper and plastic pipes have become more popular in recent years due to their ease of installation, lower cost, and better resistance to certain types of corrosion.

- Q: How are steel pipes used in the infrastructure development?

- Steel pipes are widely used in infrastructure development for various purposes such as water supply, sewage systems, gas pipelines, and transportation of oil and natural gas. They provide a durable and efficient solution for the construction of underground and aboveground infrastructure, ensuring the safe and reliable transportation of fluids and gases. Steel pipes are also used in the construction of bridges, buildings, and other structural components, as they offer strength, versatility, and resilience to withstand harsh environmental conditions.

- Q: Can steel pipes be used for underground water lines?

- Yes, steel pipes can be used for underground water lines.

- Q: How are steel pipes protected against lightning strikes?

- Steel pipes are protected against lightning strikes by installing lightning rods or grounding systems on top of the structures where the pipes are located. These systems help to divert the electrical discharge from lightning strikes, reducing the risk of damage to the steel pipes.

- Q: Could you tell me what difference between SC galvanized steel pipe and MT wire pipe?

- SC galvanized steel pipe, its pipe wall thickness, generally 20 steel pipe in 2.2-2.8mm. Also, we often refer to tap water galvanized steel pipe.MT wire pipe, its pipe wall is thin, generally 20 steel pipe in 1.5-2.2mm.

- Q: Can steel pipes be used for irrigation systems?

- Yes, steel pipes can be used for irrigation systems. They are strong, durable, and resistant to corrosion, making them suitable for transporting water and withstanding outdoor conditions. However, it is important to ensure proper insulation and maintenance to prevent any potential rust or degradation.

- Q: How do you calculate the maximum allowable deflection for steel pipes?

- To calculate the maximum allowable deflection for steel pipes, you need to consider various factors such as the pipe diameter, material properties, support conditions, and the desired level of deflection. The maximum allowable deflection is typically determined based on industry standards and codes. One commonly used method for calculating the maximum allowable deflection is based on the pipe's span-to-diameter ratio (L/D ratio). The L/D ratio is the ratio of the pipe's span (distance between supports) to its diameter. Several industry codes provide guidelines on the maximum allowable deflection based on the L/D ratio. For example, the American Society of Mechanical Engineers (ASME) B31.1 Power Piping Code suggests that for carbon steel pipes, the maximum allowable deflection should not exceed 3% of the pipe's span for an L/D ratio of 100 or less. However, for higher L/D ratios, the deflection limit decreases, ensuring the pipe's stability and structural integrity. To calculate the maximum allowable deflection using the L/D ratio method, you would first determine the L/D ratio based on the span and diameter of the pipe. Then, referring to the applicable code or standard, you can find the corresponding maximum allowable deflection limit. It is important to note that other factors such as the pipe material's yield strength, wall thickness, and the type of loading (e.g., dead load, live load) also influence the maximum allowable deflection. Therefore, it is crucial to consult the relevant industry standards, codes, and engineering principles to accurately calculate the maximum allowable deflection for steel pipes.

- Q: What are the different types of steel pipe valves?

- There are several different types of steel pipe valves that are commonly used in various industries and applications. Here are some of the most common types: 1. Gate valves: These valves are designed to control the flow of fluid by lifting or lowering a gate or wedge that obstructs the flow path. They provide a tight seal when closed and are commonly used in applications that require a full flow or complete shut-off. 2. Globe valves: Globe valves have a globe-shaped body and a movable plug or disc that regulates the flow of fluid. They offer good throttling capabilities and are used in applications where precise control of flow is required. 3. Ball valves: Ball valves use a rotating ball with a hole in it to control the flow of fluid. When the hole is aligned with the pipe, the valve is fully open, and when the hole is perpendicular to the pipe, the valve is closed. Ball valves are durable, reliable, and commonly used in applications that require quick and easy shut-off. 4. Check valves: Check valves allow fluid to flow in only one direction and prevent backflow. They are often used to prevent damage to pumps, compressors, and other equipment by preventing reverse flow. 5. Butterfly valves: Butterfly valves have a disc that rotates within the pipe to control the flow of fluid. They are lightweight, compact, and offer a quick shut-off. Butterfly valves are commonly used in large-scale applications such as water treatment and HVAC systems. 6. Plug valves: Plug valves have a cylindrical or conical plug that rotates within the valve body to control flow. They are simple in design, easy to operate, and offer reliable shut-off capabilities. Plug valves are commonly used in applications that require frequent operation and high pressure ratings. 7. Diaphragm valves: Diaphragm valves use a flexible diaphragm to control the flow of fluid. When the diaphragm is pressed against the valve seat, the flow is blocked, and when the diaphragm is lifted, the flow is allowed. Diaphragm valves are commonly used in applications that require a sterile or hygienic environment. These are just a few examples of the different types of steel pipe valves available in the market. The choice of valve depends on the specific application requirements, such as flow rate, pressure, temperature, and the type of fluid being transported.

- Q: What is the lifespan of steel pipes?

- The lifespan of steel pipes can vary depending on various factors such as the quality of the steel, usage conditions, maintenance, and external factors like corrosion. However, properly installed and maintained steel pipes can typically last for several decades or even a century.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2005 |

| Annual Output Value | Above US$100 Million |

| Main Markets | Main land; Middle East; Southeast Asia |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 61% - 70% |

| No.of Employees in Trade Department | 390People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 600,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM not offered |

| Product Price Range | Average |

Send your message to us

JIS G3461(Carbon Steel Tubes For Boiler And Heat Exchanger)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50mt m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords