IZ50-32-125A water pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

IZ(BL)-Series

IZ (BL)-type pumps are single stage centrifugal pump direct connection for the delivery of physical and chemical properties of water or other liquid similar to water with a temperature not higher than 80 ℃. The pump is a form of small, light weight, simple structure, low noise, and easy assembly and disassembly. Shaft seal mechanical seal, seal. Applicable to factories, mines, urban water supply and drainage, high-rise building pressurized water and irrigation.Motor power:1.5-7.5kw,Flow:11.8-50m/h,Head:17.6-32m。

| ■List of performance | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

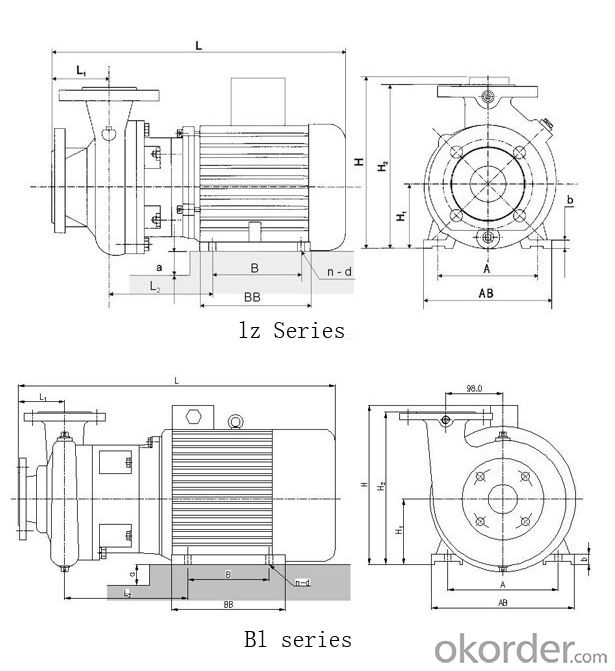

| ■Installation size map | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

■Installation Dimension Table

| Type | L | L1 | L2 | B | BB | A | AB | n-d | b | H2 | H1 | a | H |

| IZ50-32-125A | 457 | 80 | 143 | 125 | 155 | 140 | 180 | 4-10 | 15 | 230 | 90 | 50 | 237 |

| IZ50-32-125 | 457 | 80 | 143 | 125 | 155 | 140 | 180 | 4-10 | 15 | 230 | 90 | 50 | 236 |

| IZ65-50-125 | 493 | 80 | 160 | 140 | 176 | 160 | 194 | 4-12 | 15 | 243 | 100 | 50 | 261 |

| IZ50-50-160 | 538 | 80 | 185 | 140 | 182 | 190 | 232 | 4-12 | 17 | 267 | 112 | 60 | 285 |

| BL50-50-160 | 538 | 80 | 185 | 140 | 182 | 190 | 232 | 4-12 | 17 | 267 | 112 | 60 | 285 |

| IZ65-40-130 | 598(551) | 80 | 243(196) | 140 | 178 | 190 | 232 | 4-12 | 15 | 255 | 112 | 50 | 291 |

| IZ80-65-125A | 567 | 100 | 201 | 140 | 185 | 190 | 238 | 4-12 | 17 | 272 | 112 | 60 | 285 |

| IZ80-65-125 | 620 | 100 | 220 | 140 | 200 | 216 | 273 | 4-12 | 18 | 284 | 132 | 50 | 324 |

| IZ65-50-130A | 692(628) | 100 | 283(219) | 140 | 200 | 216 | 273 | 4-12 | 18 | 284 | 132 | 50 | 324 |

| IZ80-65-160 | 618 | 100 | 216 | 140 | 200 | 216 | 273 | 4-12 | 18 | 284 | 132 | 50 | 324 |

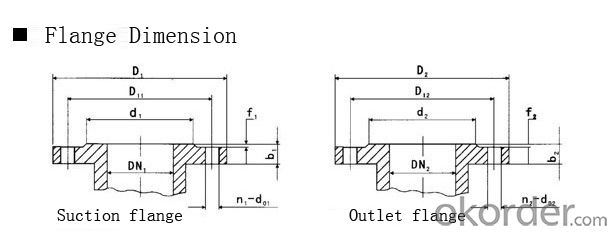

■Flange Size Chart

| Type | Suction flange size | Row outlet flange size | ||||||||||||

| DN1 | D1 | D11 | d1 | b1 | f1 | n1-dm | DN2 | D2 | D12 | d2 | b2 | f2 | n2-dm | |

| IZ50-32-125A | 50 | 165 | 125 | 102 | 18 | 3 | 4-φ17.5 | 32 | 140 | 100 | 78 | 18 | 3 | 4-φ17.5 |

| IZ50-32-125 | 50 | 165 | 125 | 102 | 18 | 3 | 4-φ17.5 | 32 | 140 | 100 | 78 | 18 | 3 | 4-φ17.5 |

| IZ65-50-125 | 65 | 185 | 145 | 122 | 19 | 2 | 4-φ17.5 | 50 | 165 | 125 | 102 | 19 | 2 | 4-φ17.5 |

| IZ50-50-160 | 50 | 140 | 110 | 90 | 14 | 2 | 4-φ14 | 50 | 160 | 125 | 100 | 14 | 2 | 4-φ18 |

| BL50-50-160 | 50 | 140 | 110 | 90 | 14 | 2 | 4-φ14 | 50 | 160 | 125 | 100 | 14 | 2 | 4-φ18 |

| IZ65-40-130 | 65 | 185 | 145 | 124 | 19 | 2.5 | 4-φ17.5 | 40 | 150 | 110 | 86 | 20 | 2.5 | 4-φ17.5 |

| IZ80-65-125A | 80 | 200 | 160 | 133 | 21 | 2.5 | 8-φ17.5 | 65 | 185 | 145 | 122 | 19 | 2.5 | 4-φ17.5 |

| IZ80-65-125 | 80 | 200 | 160 | 133 | 21 | 2.5 | 8-φ17.5 | 65 | 185 | 145 | 122 | 19 | 2.5 | 4-φ17.5 |

| IZ80-65-130A | 65 | 185 | 145 | 124 | 19 | 2.5 | 4-φ17.5 | 50 | 165 | 125 | 104 | 20 | 2.5 | 4-φ17.5 |

| IZ80-65-160 | 80 | 200 | 160 | 133 | 21 | 2.5 | 8-φ17.5 | 65 | 185 | 145 | 122 | 20 | 2.5 | 4-φ17.5 |

- Q: A residential building with a floor height of 11 stories and a roof height of 33 meters. The height of the water tank is 37.7 meters. The basement is -3.3 meters, only set fire hydrant, fire pump only consider the indoor fire water, fire flow should be 10l/s. Now select a fire pump, concrete should be much traffic, big head, flow determine how? How to determine the head, I hope to say some more detailed, thank you, and there is to explain this question, why is the fire pump lift 120?. Thank you

- According to the water quantity form fire flow water supply system fire safety in high-rise building fire hydrant pump lift is 10L/s, accurate algorithm is to say after a simple calculation with each indoor hydrant flow is two 5L/s bolt so to get the most unfavorable point for the calculation unit to calculate the minimum requirements, with the most unfavorable point suppository pressure specifications 0.07MPa, partial loss of the most unfavorable line and the line (according to the equivalent length) and loss (according to the material resistance coefficient), and finally the pump head loss of gravity difference. But we just calculate the construction elevation difference multiplied by 110% to 120% to determine the head {there is a need to know is: conversion head (m), (kg) and MPa kg 1MPa=10 kg = 100m is the vertical water column on unit area pressure conversion

- Q: Why should the pump be closed when the centrifugal pump is started?

- Centrifugal pump has an important characteristic: when the pressure (head) is very low, the flow will be great, which can be seen from the characteristics of the pump curve. While the pump power is directly proportional to the flow rate, pump start, no pressure in the pipeline, caused by the pump flow, high power pump, and the pump motor, the rotating part from rest to high-speed operation, need a lot of acceleration, it will cause a great starting current

- Q: If the suction pump does not have enough suction range, you need to add a vacuum pump to increase the suction stroke. How do you install the suction pipe of the vacuum pump? Water pump impeller is not closed, it is normal that the vacuum pump is unable to pump suction pipe to a vacuum, is it because the water pump outlet pipe connected to the role of the check valve? But the water pump, outlet pipe, check valve sealing performance can achieve the function of non leakage?

- The role of the check valve:"[the water pump impeller is not closed" refers to the pump suction pump before the water without water inlet pipe and water outlet pipe gas should be connected] is a connector, a connector, still can make the level surface, in order to prevent the water flow along the pipe, until it reaches the level of the flush, then increased check valve, or pumping up water will not leak?Vacuum suction principle of self suction pump:Assuming that the pump connected with the water inlet of a sealed container, the container has plenty of water, since the start of a water pump, water is thrown out of the water impeller pump body, water inlet seal vessel due to the extraction of water to form a vacuum cavity, this assumption will be connected to vacuum cavity and exposed to atmospheric conditions of water, water at atmospheric pressure under the effect of entry into the vacuum chamber".....

- Q: What are the ways of hydraulic pumps?

- Hydraulic pump is a power component of hydraulic system. It is driven by an engine or an electric motor. It draws oil from the hydraulic tank to form a component of the pressure oil which is sent to the actuating element.

- Q: What does "anti pump" mean in pump operation?

- Function: anti pump effect when used for pumping concrete pumping occurs overpressure, the pumping pressure is above 25MPA, the concrete conveying pipe out of ash, can be understood as the precursor of pipe blockage, at this time should immediately use the anti pump, the concrete from the conveying pipe in the suction into the hopper, thus preventing plugging happen

- Q: What's the difference between non negative pressure and variable frequency water pump?

- Re pressure to a given pressure pressure zone water supply, than frequency conversion water pump energy savingFrom a health perspective, a water tank variable frequency water pump, water tank and the atmosphere, easy occurrence of water pollution two, no negative pressure equipment without negative pressure tank and pump and valve fittings etc., no water tank, the whole process of water supply of water is completed in a closed system, with air contact to avoid two pollution problems water supply.From the management point of view, no negative pressure is fully automatic intelligent operation, reduce management costs, no water tank, reducing the trouble of tank cleaning. No negative pressure is the upgrading of variable frequency water pump products

- Q: I live on the 8 floor. Often there is no water. Life is very inconvenient. What kind of pump do I have to install? What should I pay attention to when I buy it? What's the pump for that brand? Should it be installed in that position?

- Installation method of hydraulic pump(1) according to the technological requirements and the cavitation conditions of the pump, the installation height check and the civil engineering of the foundation are carried out.(2) prepare a series of flat washers and wedge gaskets of different thickness before installation.(3) according to the characteristics of the pump conveying medium, determine the material of the gasket at the connection and process the gasket.

- Q: What is the pump delivery? What's the difference between years and years?

- First of all, as a student majoring in insurance, I strongly condemn the first floor of ignoring practice and trampling on real knowledge!!The insurance industry criticized a lot, but it is required for many people, we should face and try to maintain the healthy development of the industry, the first floor of the insurance you have not done, have no contact with the insurance, insurance, not to dictate the nonsense, more should not be here misleading!

- Q: What is the difference between centrifugal pump and rotary vane pump? What are the distinctive characteristics or principles of rotary and centrifugal? O (a _ U) O thank you!

- The vane pump can be divided into centrifugal pump, mixed flow pump and axial flow pump according to the direction of liquid flow in the impeller.Centrifugal pump is a kind of vane pump, which is the most widely used.

- Q: Household automatic booster pump, how much pressure to work automatically, the water pressure and how many kilograms?

- Start the pump. Water pressure depends on how large you buy the pump, generally small, mostly 10-15 meters hydraulic pressure, about 200 of the price.

Send your message to us

IZ50-32-125A water pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches