IZ65-40-130A water pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

IZ(BL)-Series

IZ (BL)-type pumps are single stage centrifugal pump direct connection for the delivery of physical and chemical properties of water or other liquid similar to water with a temperature not higher than 80 ℃. The pump is a form of small, light weight, simple structure, low noise, and easy assembly and disassembly. Shaft seal mechanical seal, seal. Applicable to factories, mines, urban water supply and drainage, high-rise building pressurized water and irrigation.Motor power:1.5-7.5kw,Flow:11.8-50m/h,Head:17.6-32m。

| ■List of performance | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

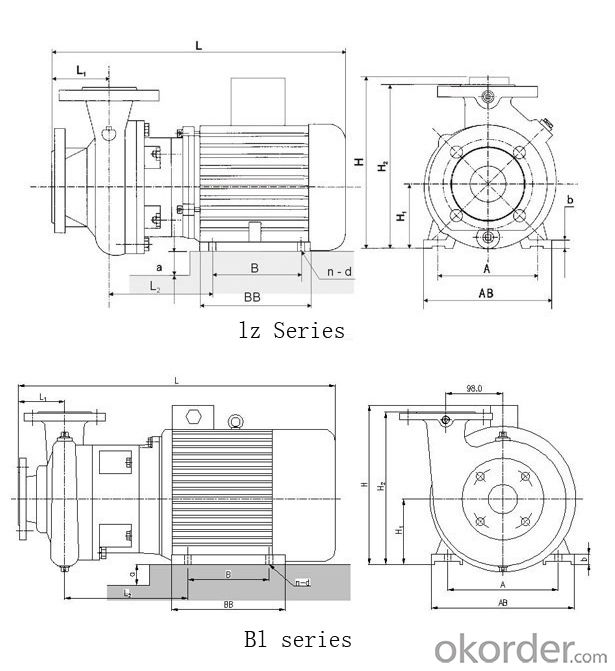

| ■Installation size map | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

■Installation Dimension Table

| Type | L | L1 | L2 | B | BB | A | AB | n-d | b | H2 | H1 | a | H |

| IZ50-32-125A | 457 | 80 | 143 | 125 | 155 | 140 | 180 | 4-10 | 15 | 230 | 90 | 50 | 237 |

| IZ50-32-125 | 457 | 80 | 143 | 125 | 155 | 140 | 180 | 4-10 | 15 | 230 | 90 | 50 | 236 |

| IZ65-50-125 | 493 | 80 | 160 | 140 | 176 | 160 | 194 | 4-12 | 15 | 243 | 100 | 50 | 261 |

| IZ50-50-160 | 538 | 80 | 185 | 140 | 182 | 190 | 232 | 4-12 | 17 | 267 | 112 | 60 | 285 |

| BL50-50-160 | 538 | 80 | 185 | 140 | 182 | 190 | 232 | 4-12 | 17 | 267 | 112 | 60 | 285 |

| IZ65-40-130 | 598(551) | 80 | 243(196) | 140 | 178 | 190 | 232 | 4-12 | 15 | 255 | 112 | 50 | 291 |

| IZ80-65-125A | 567 | 100 | 201 | 140 | 185 | 190 | 238 | 4-12 | 17 | 272 | 112 | 60 | 285 |

| IZ80-65-125 | 620 | 100 | 220 | 140 | 200 | 216 | 273 | 4-12 | 18 | 284 | 132 | 50 | 324 |

| IZ65-50-130A | 692(628) | 100 | 283(219) | 140 | 200 | 216 | 273 | 4-12 | 18 | 284 | 132 | 50 | 324 |

| IZ80-65-160 | 618 | 100 | 216 | 140 | 200 | 216 | 273 | 4-12 | 18 | 284 | 132 | 50 | 324 |

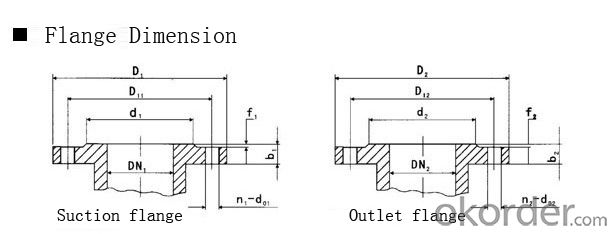

■Flange Size Chart

| Type | Suction flange size | Row outlet flange size | ||||||||||||

| DN1 | D1 | D11 | d1 | b1 | f1 | n1-dm | DN2 | D2 | D12 | d2 | b2 | f2 | n2-dm | |

| IZ50-32-125A | 50 | 165 | 125 | 102 | 18 | 3 | 4-φ17.5 | 32 | 140 | 100 | 78 | 18 | 3 | 4-φ17.5 |

| IZ50-32-125 | 50 | 165 | 125 | 102 | 18 | 3 | 4-φ17.5 | 32 | 140 | 100 | 78 | 18 | 3 | 4-φ17.5 |

| IZ65-50-125 | 65 | 185 | 145 | 122 | 19 | 2 | 4-φ17.5 | 50 | 165 | 125 | 102 | 19 | 2 | 4-φ17.5 |

| IZ50-50-160 | 50 | 140 | 110 | 90 | 14 | 2 | 4-φ14 | 50 | 160 | 125 | 100 | 14 | 2 | 4-φ18 |

| BL50-50-160 | 50 | 140 | 110 | 90 | 14 | 2 | 4-φ14 | 50 | 160 | 125 | 100 | 14 | 2 | 4-φ18 |

| IZ65-40-130 | 65 | 185 | 145 | 124 | 19 | 2.5 | 4-φ17.5 | 40 | 150 | 110 | 86 | 20 | 2.5 | 4-φ17.5 |

| IZ80-65-125A | 80 | 200 | 160 | 133 | 21 | 2.5 | 8-φ17.5 | 65 | 185 | 145 | 122 | 19 | 2.5 | 4-φ17.5 |

| IZ80-65-125 | 80 | 200 | 160 | 133 | 21 | 2.5 | 8-φ17.5 | 65 | 185 | 145 | 122 | 19 | 2.5 | 4-φ17.5 |

| IZ80-65-130A | 65 | 185 | 145 | 124 | 19 | 2.5 | 4-φ17.5 | 50 | 165 | 125 | 104 | 20 | 2.5 | 4-φ17.5 |

| IZ80-65-160 | 80 | 200 | 160 | 133 | 21 | 2.5 | 8-φ17.5 | 65 | 185 | 145 | 122 | 20 | 2.5 | 4-φ17.5 |

- Q:How many square cables does the submersible pump for 7.5KW need?

- According to current I=13A, it is estimated that the cable is less than 10 square meters, so the cable cross section can be calculated at the ampacity of 5A per square meter. The square section of the cable is =13/5=2.6 square. According to the specifications series, optional 2.5 square aluminum cables. When the cable is longer, it is safer to choose 4 square aluminum cables.

- Q:Significance of water pump model ISO50-160

- According to different working principles can be divided into volumetric pumps, vane pumps and other types. Displacement pump is to use its studio volume changes to transfer energy; vane pump is to use the rotating blade and water interaction to transfer energy, there are centrifugal pumps, axial flow pumps and mixed flow pumps and other types.

- Q:What is the displacement of the pump? Flow? What is the volume efficiency and mechanical efficiency of the pump?

- Mechanical efficiency: the ratio of theoretical torque to actual torque of the pump.

- Q:Please give me professionals to calculate, the cylinder bore is 100 and the rate of 20m/s, the leakage can be ignored, but to the large flow pump!

- Select the hydraulic pump from the following considerations:1. hydraulic pump pressureHydraulic pump operating pressure is the pump (or motor) in actual work output (or input) oil pressure, determined by the external load.Rated pressure refers to the maximum pressure under continuous running in accordance with the test standards under normal working conditions. The size of the pump is limited by the service life, and the service life of the pump (or motor) will be shorter than the design life if it exceeds the rated pressure. When the work pressure is greater than the rated pressure, it is called overload.

- Q:The difference between submersible pumps and centrifugal pumpsWhat's the difference between the two? What is applicable and what?

- Difference:The installation position is different: one can discharge water, one is on the ground.The work principle is different: the principle of submersible pump is similar to the electric fan, centrifugal pump through centrifugal force to make the water throw out. According to the principle of centrifugal force design,

- Q:Why should I pump the pump before starting the centrifugal pump?

- Before the operation of the centrifugal pump, the pump must be filled with water, exhaust the air, before you start the operation. All centrifugal pumps should be handled this way, which is the centrifugal pump itself.The way of water diversion:1., in the centrifugal pump outlet increase water diversion pump (usually using vacuum pump), start the centrifugal pump before, start the vacuum pump, the centrifugal pump air into;2. increase the vacuum water tank before the intake of the centrifugal pump to meet the working conditions of the centrifugal pump;3. in the centrifugal pump inlet water increase valve, to meet the working conditions of centrifugal pump;4., if the water tank or water tank volume of water level is higher than the centrifugal pump position, the first operation of the front row empty, usually do not empty, you can use.

- Q:No negative pressure water supply equipment, both the main pump and auxiliary pump, power is not the same, how to choose the control cabinet?

- Non negative pressure variable frequency water supply means no negative pressure superposed water supply equipment. When running, it is connected directly to the water supply pipe. Always test the pressure of tap water pipe network and water supply pipe network pressure control system, when the water pressure is lower than the pressure required by the user, the frequency conversion device based on water automatically control the pump speed through the steady flow compensator of water balance, maintain a constant pressure water supply. In the multi pump system, the control system can automatically dispatch the water pump according to the water consumption. It can balance the working time of the pump and ensure the pressure of the water supply. When the water supply pressure satisfy the required pressure, the system automatically stops the pump by the external water supply pipe network directly. CJWFG-DYG non negative pressure superposed water supply system:

- Q:Direct connection pump What is straight pump and non direct pump? What's the difference in structure?

- What is straight pump and non direct pump? Direct coupled pump shaft and the motor shaft is directly coupled with the coupling and non direct coupled pump: pump shaft and motor shaft through the belt pulley, V-belt connection or other forms of transmission. What is the difference in the structure: the direct coupled pump has the advantages of compact structure, simple installation, but the relatively small power; non direct coupled pump: pump and motor is independent, the two transfer torque through the belt, the structure is relatively large, complex installation, general power is relatively large.

- Q:What are the basic technical parameters of the pump?

- The effective power of pump and output power, with Pe said. It is the effective energy per unit time from the pump in conveying out liquid obtained in the pump. Because the lift refers to the effective energy, pump output unit of heavy liquid obtained from the pump so that the product of head and the mass flow rate and the acceleration of gravity. Is to obtain the output from the pump in unit time of liquid effective energy - efficient pump power: Pe= P gQH (W) = QH (W) - P - density of liquid pumping (kg/m3); severe gamma - pump for transporting liquid (N/m3) - Q (pump flow; m3/s; H) - pump head (m); G (m/s2). The acceleration of gravity P axle power and effective power Pe is the difference of power loss in the pump, the size of the pump efficiency to measure the efficiency of the pump. As the effective power and shaft power ratio, with ETA said. Selection of related pumps:

- Q:What is the pumping property of concrete?

- Pumping capacity means that fresh concrete can be transported by concrete pump, and concrete construction can be carried out with high efficiency. 'pumping' is a qualitative statement

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

IZ65-40-130A water pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords