Irradiation cross-linkable PVC compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 3000 Tons kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Irradiationcross-linkable PVC compound

I. Type andapplication

Type | Product | Application and Cable Specification |

1151N | 105℃ Irradiation cross-linkable PVC insulating compound | Used for irradiation cross-linkable cables and wires which working temp. of conductor is 105℃ |

1152N | 105℃ Irradiation cross-linkable PVC jacket compound | Used for irradiation cross-linkable cables and wires which working temp. of conductor is 105℃ |

1151N-R | 105℃ Irradiation cross-linkable PVC insulating compound | Used for irradiation cross-linkable cables and wires which working temp. of conductor is 105℃, according with JASO D618-2008 XLPVC standard. |

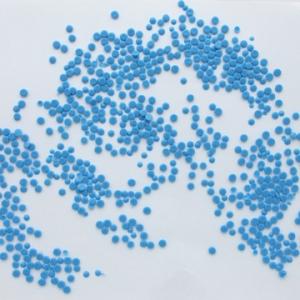

II. Productdescription

Irradiation cross-linkable PVC compound forcables and wires, based on PVC resin, is made into granula by specialprocessing with adding plasticizer, stabilizing agent, cross-linking agent andother special agents. The products meet various special requirements, such asdifferent hardness, UV stable, environment friend (RoHs, REACH, PAHs,chlorinated alkanes free, phthalatefree, and etc.), sub-shine and fog surface, low temperature resistant, PS/ABStransfer proof, rodent-repellent, termite-repellent, and transparent, and etc.

III. Irradiatingdosage

The normalirradiating dosage of irradiation cross-linkable PVC compound is 6-8 mega-rad.

Note: For the compound would be coloured if the white and nature colourcompound were irradiated directly, the compound need add white colourmasterbatch before processing.

IV. Processing

It is recommended that compound should beprocessed with common extruder having a minimum L/D ratio of 20. Non-specialrequirements of equipment and processing are needed.

The following temperature(℃) profileof extruder is recommended

Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | Die |

Temperature ℃ | 140 | 160 | 170 | 175 | 180 | 175 |

V. Storageand transport

Packaging:25kg/bag, PEmembrane inside bag and Kraft outside bag.

Storage and transport: Avoiding in directsunlight and weathering. The storage place should be in clean, cool, dry, andventilated conditions.

VI. Properties

Table

Item | Unit | Standard Value | |||

1151N | 1152N | 1151N-R | |||

Tensile Strength | ≥ MPa | 16.0 | 15.0 | 16.0 | |

Elongation at Break | ≥ % | 150 | 180 | 150 | |

Impact Brittleness Temperature | ≤ ℃ | -15 | -20 | -20 | |

Volume Resistivity, at 20℃ | ≥Ω﹒m | 1.0×1011 | 1.0×108 | 1.0×109 | |

Volume Resistance at working temperature | Temperature | ℃ | 95±1 | — | — |

Volume Resistance | ≥Ω﹒m | 1.0×108 | — | — | |

Dielectric Strength | ≥ MV/m | 20 | 18 | 20 | |

Hot Deformation | ≤ % | 40 | 50 | 40 | |

Thermal Stability Time at 200℃ | ≥ min | 120 | 120 | 120 | |

Oxygen Index | ≥ % | - | 26 | — | |

Thermal Prolongation Elongation Under Load | ≤ % | 175 | 175 | 175 | |

Thermal Aging |

|

|

|

| |

Aging Temperature | ℃ | 136±1 | 136±1 | 136±1 | |

Aging Time | h | 168 | 168 | 168 | |

Retention of Tensile Strength | ≤ % | +80 | +80 | +80 | |

Retention of Elongation at Break | ≤ % | +75 | +70 | +75 | |

Note: The above data are the compoundproperties after irradiated.

- Q: What materials do you use for plastic moulds?

- As there are many varieties of plastics, the requirements for plastic products vary greatly, and various materials for making plastic moulds are also put forward

- Q: What sizes are olive nets available in?

- Olive nets are available in various sizes, ranging from small to large, to accommodate different olive tree sizes and grove configurations.

- Q: Can olive nets be used in olive groves with high bird populations?

- Olive nets can be used in olive groves with high bird populations as they are specifically designed to protect the olives from being eaten by birds. These nets act as a physical barrier, preventing birds from accessing the fruit. However, it is important to regularly monitor and maintain the nets to ensure their effectiveness and prevent any entanglement of birds.

- Q: Can olive nets be used in combination with precision farming techniques?

- Yes, olive nets can be used in combination with precision farming techniques. Olive nets are commonly used to collect olives during the harvesting process, while precision farming techniques involve using technology and data to optimize farming operations. By incorporating precision farming techniques such as GPS mapping, remote sensing, and yield monitoring, olive farmers can strategically place nets based on the data obtained from precision farming practices to maximize efficiency and yield. This combination can help improve the overall productivity and sustainability of olive farming.

- Q: How many years will it take for a plastic bag to rot?

- Buried in the ground requires more than 200 years to rot, and seriously pollute the soil, and the burning of harmful smoke and fumes and toxic gases, the same will cause pollution of the atmospheric environment. Therefore, our country advocates the use of environmentally degradable plastic bags

- Q: Can olive nets be used in combination with pruning tools and equipment?

- Yes, olive nets can be used in combination with pruning tools and equipment. Olive nets are typically used to catch the olives as they are being pruned from the tree, ensuring that they don't fall to the ground and get damaged. The nets can be spread out under the tree while using pruning tools and equipment to collect the olives more efficiently.

- Q: Are olive nets easy to install?

- Yes, olive nets are generally easy to install. They are designed to be lightweight and flexible, allowing for straightforward setup and removal. The process usually involves spreading the net over the tree canopy and securing it in place using ropes or fasteners.

- Q: How do olive nets prevent bird droppings from contaminating olives?

- Olive nets prevent bird droppings from contaminating olives by creating a physical barrier between the birds and the fruit. The nets are spread over the trees, forming a protective layer that prevents birds from accessing the olives. This barrier effectively blocks the birds from perching or landing on the trees, thus minimizing the chances of droppings falling onto the olives.

- Q: What are the grades of plastics from 1 to 7?

- The first goal of plastic packaging waste treatment is to recycle and reuse containers and other resources, so as to protect the limited resources and complete the recycling of packaging containers. Among them, carbonated drinks with PET (polyethylene terephthalate) bottle 28% can be recycled, PE-HD milk bottles (HDPE), PE-HD bottles can also be effectively recycled.

- Q: Can olive nets be used for both traditional and modern irrigation methods?

- Yes, olive nets can be used for both traditional and modern irrigation methods. Olive nets are versatile and can be adapted to different irrigation techniques such as drip irrigation, sprinkler irrigation, or even flood irrigation. They can help distribute water evenly across the olive trees, preventing water wastage and promoting efficient water usage. Additionally, olive nets can also protect the soil from erosion and conserve moisture, which is beneficial for both traditional and modern irrigation approaches.

Send your message to us

Irradiation cross-linkable PVC compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 3000 Tons kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords