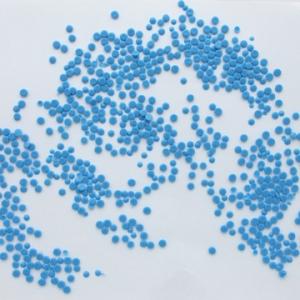

Thermoplastic elastomer PVC compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 3000 Tons kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Thermoplastic elastomer PVC compound

I. Type and application

Type | Product | Application and Cable Specification |

7006N | 70℃Thermoplastic elastomer PVC insulating compound | Insulating compound for flexible, mobile wires and cables of elevator and audio, and etc. |

7026N | 70℃Thermoplastic elastomer PVC jacket compound | Jacket compound for flexible, mobile wires and cables of elevator and audio, and etc. |

7326N | 70℃Flame retardant thermoplastic elastomer PVC jacket compound | Jacket compound for flame retardant, flexible, mobile wires and cables |

9026N | 90℃Thermoplastic elastomer PVC jacket compound | Jacket compound for flexible, mobile wires and cables at 90℃ |

0526N | 105℃Heat resistant thermoplastic elastomer PVC jacket compound | Jacket compound for heat resistant, flexible, mobile wires and cables at 105℃ |

II. Product description

Thermoplastic elastomer PVC compound for wires and cables, based onPVC resin and modified polymer, is made into granula by mixing, plastificationand granulation with adding plasticizer, stabilizing agent, flame retardant andetc. The products meet various special requirements, such as differenthardness, UV stable, environment friend (RoHs, REACH, PAHs, chlorinated alkanesfree, phthalate free, and etc.),sub-shine and fog surface, low temperature resistant, PS/ABS transfer proof,rodent-repellent, termite-repellent, and transparent, and etc.

III. Processing

It is recommended that compound should beprocessed with common extruder having a minimum L/D ratio of 20.

The following temperature(℃)profile of extruder is recommended:

Zone | Zone 1 | zone 2 | Zone 3 | Zone 4 | Head | Die |

Temperature ℃ | 140 | 150 | 160 | 165 | 165 | 165 |

IV. Storage and transport

Packaging:25kg/bag, PE membrane inside bag and Kraft outsidebag.

Storage and transport: Avoiding in directsunlight and weathering. The storage place should be in clean, cool, dry, andventilated conditions.

V. Properties

Table

Item | Unit | Standard Value | ||||

7006N | 7026N | 7326N | 9026N | 0526N | ||

Tensile Strength | ≥ MPa | 12.5 | 12.5 | 12.5 | 12.5 | 12.5 |

Elongation at Break | ≥ % | 300 | 300 | 300 | 300 | 300 |

Impact Brittleness Temperature | ℃ | -30 | -40 | -40 | -40 | -40 |

Volume Resistivity, at 20℃ | ≥Ω﹒m | 1.0×109 | 1.0×108 | 1.0×108 | 1.0×108 | 1.0×108 |

Volume Resistivity, at 70℃ | ≥Ω﹒m | 1.0×107 | - | - | - | - |

Dielectric Strength | ≥ MV/m | 18 | 18 | 18 | 18 | 18 |

Hot Deformation | ≤ % | 60 | 65 | 65 | 65 | 65 |

Thermal Stability Time at 200℃ | ≥ min | 60 | 60 | 60 | 60 | 80 |

Oxygen Index | ≥ | - | - | 26 | - | - |

Thermal Aging |

|

|

|

|

|

|

Aging Temperature | ℃ | 100±2 | 100±2 | 100±2 | 120±2 | 135±2 |

Aging Time | h | 168 | 168 | 168 | 168 | 168 |

Tensile Strength after aging | ≥ MPa | 12.5 | 12.5 | 12.5 | 12.5 | 12.5 |

Variation on Tensile Strength | % | ±20 | ±20 | ±20 | ±20 | ±20 |

Elongation at Break after aging | ≥ % | 300 | 300 | 300 | 300 | 300 |

Variation on Elongation at Break | % | ±20 | ±20 | ±20 | ±20 | ±20 |

Shore Hardness | A | 68±3 | 65±3 | 65±3 | 69±3 | 70±3 |

Elongating Shrinkage | ≤ % | 140 | 140 | 140 | 140 | 140 |

- Q: How do you glue a broken plastic basin?

- Find you a soft plastic, burn it, drop the drop of plastic in the dew place!!

- Q: Do all plastics have plasticizers?

- There are many kinds of plasticizers and only a few of them are toxic. The key is to see whether the manufacturer of the product you have has a conscience, and whether the authorities concerned have done anything about it.

- Q: Can olive nets be used in olive groves with limited space for storage?

- Yes, olive nets can be used in olive groves with limited space for storage. Olive nets are lightweight and flexible, making them easy to install and remove as needed. They can be folded or rolled up for compact storage, allowing olive grove owners with limited space to store them conveniently.

- Q: How do olive nets prevent fruit fermentation in olives?

- Olive nets prevent fruit fermentation in olives by providing a physical barrier that prevents the olives from coming into contact with oxygen. This reduces the chances of fermentation occurring, as fermentation requires oxygen to take place. Additionally, olive nets also help to protect the olives from pests and birds, which can damage the fruit and increase the risk of fermentation.

- Q: How do I store olive nets when not in use?

- To store olive nets when not in use, it is best to clean them thoroughly to remove any dirt or debris. Afterward, allow them to dry completely to prevent mold or mildew growth. Then, neatly fold or roll the nets and store them in a cool, dry place, preferably in a sealed container or bag to protect them from dust or pests.

- Q: Can olive nets be installed by one person?

- Yes, olive nets can typically be installed by one person. However, the ease of installation may vary depending on the size and height of the olive tree, as well as the specific design of the net.

- Q: How effective are olive nets at preventing fruit damage?

- Olive nets are highly effective at preventing fruit damage. They create a physical barrier that protects the olives from birds, insects, and other potential threats. These nets also minimize the risk of bruising or falling during harvesting. Overall, olive nets play a crucial role in preserving the quality and quantity of the fruit yield.

- Q: Are olive nets suitable for both young and mature olive trees?

- Yes, olive nets are suitable for both young and mature olive trees. Olive nets are specifically designed to protect the trees from birds and other animals that may damage the fruit. Regardless of the age of the tree, using olive nets can effectively prevent unwanted pests and ensure a successful harvest.

- Q: Can olive nets be used in olive groves with limited access to roads?

- Yes, olive nets can be used in olive groves with limited access to roads. Olive nets are lightweight and easy to transport, making them suitable for use in groves with limited road access. Additionally, they can be installed and removed manually, allowing for convenience and flexibility in groves that may not have machinery or vehicles readily available.

- Q: How much do olive nets typically cost?

- The cost of olive nets typically varies depending on the size, material, and quality of the net. On average, you can expect to pay anywhere between $50 to $200 for olive nets.

Send your message to us

Thermoplastic elastomer PVC compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 3000 Tons kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords