Iron Manhole Cover from Casting Foundry

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 110 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Quick Details

1.Place of Origin: Hebei, China (Mainland)

2.Brand Name: CMAX

3.Model Number: EN124 Standard

4.Application: Construction

5.Material: Iron

6.Dimensions: OEM

7.Surface treatment: Painting

8.Process: Casting. Drilling. Threading

9.Certification: ISO9001:2008

10.Standard: EN124 Standard

11.Name: Iron Casting Parts

12.Color: Grey

13.Type: Moulding Press

14.Service: OEM Service

15.Size: Customer's Request

Advantage of ductile iron

Higher quality /higher tensile

Higher security /long life

Packaging and Shipping

Delivery Detail: 8 days if your order is 20"container

Packaging: Details Pallet with bubble film, Carton or with pallet

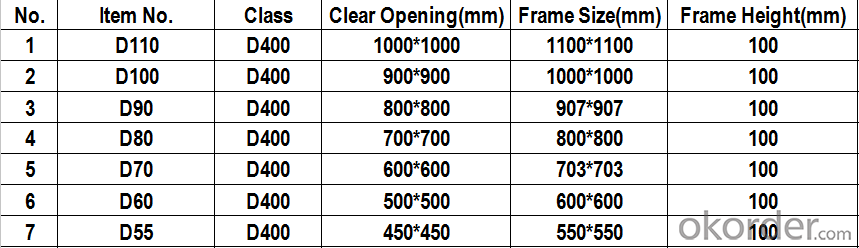

Specification

Our Company

We take pride to introduce ourselves as the leading manufacturer and professional supplier of various Ductile Iron Manhole covers in China with total annual capacity 50,000 MT.

CNBM manhole cover regard quality as the essential factor leading to successful business. After years of efforts, CNBM manhole cover have built up great reputation in terms of quality and service among domestic and overseas customers.

Our Services

1. Sample is available for free.

2. OEM and ODM are welcome.

3. Free charge of design labels and cartons.

4. Professional technical support with free charge.

5. After the cooperation: Any of your problem will be solved within 24 hours.

- Q: Casting blank in the cooling process to release a large amount of heat energy, what can be recycled?

- General Casting Factory Casting Division will be in your chart marked on shrinkage and processing margin figure (usually with red and green pen) to the patternmaker production of wood or other material mould diagram.

- Q: In theory, which is more expensive, forging parts or casting parts?

- The structure of the casting is relatively flexible in design, and the modeling is easy to realize.

- Q: the parts of the threaded hole is casting, casting the hole directly, and then tapping or casting, and then punch 10When the casting is ready, punch it again before tapping it Is the hole casting good or is it punched and tapped on the drilling machine after casting?

- If it is not directly cast hole hole, later processing, large pores may be directly cast out,

- Q: The cause of fracture and why there is no toughness

- This question is too broad, see what the casting casting Oh in order to reduce the wayward cast steel, ductile iron, gray iron and white iron, you can choose the material according to their own requirements.

- Q: What are the causes of pitting on the surface of a precision casting?

- There is a bump on the mold. Or casting cooling fast.

- Q: As shown, how do I achieve the tightness test of this product, and achieve industrial production? Seek expert advice.

- Precise and tight sealing of the surface to which the test piece is to be tested, equipped with an airtight test instrument, and an electrical control system. You can complete automated testing equipment

- Q: We are small castings, the need for surface treatment of shot blasting machine, about how much?

- The choice of shot blasting machine, this is according to the workpiece size, yield, whether can collision, and the working time and other factors considered, while the price of different blasting machine are not the same, but the vast majority of small castings used crawler shot blasting machine, according to the comprehensive consideration of factors such as yield, size of workpiece commonly used on the market the crawler shot blasting machine has Q324, Q326, Q328, Q3210, and each time the amount of their treatment were 125KG, 200KG, 400KG, 600KG, the specific use of what types also need to be determined according to the actual situation

- Q: When there is no flaw detection for large casting parts, is there any crack inside?

- Cracks are considered serious levels of defects and should be repaired

- Q: Which master knows how the casting tolerances for malleable iron, gray iron and ductile iron should be chosen? Hurry up, thank youCan you provide a tolerance scale for castings, please?

- Our country has a national standard for casting tolerance levels. This national standard applies to you in malleable iron, grey cast iron, and ductile iron.

- Q: ZGMn13 casting parts processing, with what knife head good?

- The ZGMn13 itself is not have processing, if only the processing point, sharpening, ordinary can, if the processing area is relatively large, ZGMn13 external impact load is bigger, its surface wear resistance is high; the two is with the gradual wear of surface hardening, the hardening layer is continuously formed new if you have suggestions, processing, plasma cutting or flame cutting try

Send your message to us

Iron Manhole Cover from Casting Foundry

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 110 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords