interior board

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 120000pcs pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

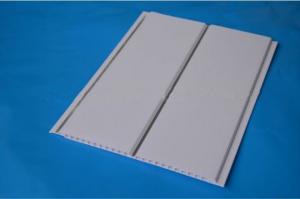

1,LUTAI Fiber cement board is a stable performance and light weight building &decoration board used cement as major and natural reinforced, with the process of pulping,emulsion,forming,pressurization,autoclaving,

drying and surface treatment.

Thickness : 4.5mm-30mm

Size :1200*2400mm, 1220*2440mm, any size that u need .

Surface : 40#-120# sanding surface , polished surface , tapered edge .

2,Product characteristics :

Density : 1.2-1.5G/CM3

Fire-proof Rate : A-Class incombustible (GB8624-1997)

Incombustibility(min): 240 minutes (GB/T9978-1999)

Water content : ≤30% Swelling ratio: ≤0.4%

Anti-bending Strength: ≥16MPA Frost resistance : Don’t appear cracking and delamination after 25 cycles of freezing and thawing . (GB/T7019-1997)

Radioactivity: standard of GB6566-2001 (A-class Decoration Materials)3,Recommed application:

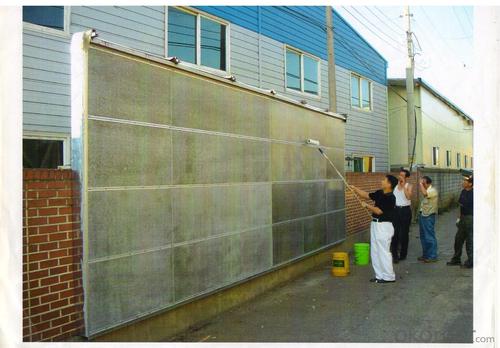

Partition board , exterior wall cladding , panel, suspended ceilings ,lightweight grouting panel, interior dry wall decoration board ,interior wall after painting and coating .

- Q: We're tiling our basement. The floor is plain concrete. Do I need to put a layer of plywood, then a layer of cement board, then the tiles, or do I just need a layer of cement board then the tiles?

- If the concrete is solid without big voids or decomposing or something like that I would say you can just apply adhesive directly to concrete and start setting your tile. But I'm The Door Guy.....You should probably hear from the tile guy!! Good luck!

- Q: I would like to build 4 steps on a incline. It is above a retaining wall but will be a good foot away from the wall all on firm packed dirt. I have a couple questions. One side of the steps would be next to the garage wall.1. Can I pour cement up against the cinder wall?2. If so how would someone build steps form without any boards against the one side. So basically just have the one side and front plate.3. Or would you recommend having a board against the wall. Or pull it out after the form has set?

- have you thought of buying a precast fiberglass step, they go well with weather, they are strong and you can pain them if you like. Home Depot might have some

- Q: I am laying a new tile floor over plywood subfloor. I have Durock cement backerboard. The area I'm covering is only 4'3 x 6'8. I don't really want to put the money out for power saws ($60+) so I am planning to use a hand saw. What kind is most appropriate? Can I use a small utility knife for the smaller details?

- I think most guys just use a utility knife (with a sharp blade) to score the board and snap it kind of like drywall. You'll use a few blades but I think it'd work fine. Use the fasteners recommended by the manufacturer. I see a lot of roofing nails being used but I don't think they're the best thing to use. The Durock wasn't cheap and neither is the tile you'll be installing. Don't try to save fifty cents on fasteners.

- Q: where can i buy national gypsum perma base cement board?

- Haven't thought about that

- Q: I'm ready to tile my kitchen soon. My husband and I have torn up the carpet and 2 layers of linoleum, leaving only some leftover glue from the linoleum and the wood sub floor. Do we really need to lay cement board over the wood sub floor or can we just go ahead and tile right on the wood? (FYI: it will be either ceramic or porcelain tile)

- Yes, unfortunately you will. If you tile directly onto the sub floor, the tile is likely to develop cracks. The sub-floor is probably 3/4 material, so an additional 1/2 thick cement board should work.

- Q: Can someone tell me if they know or what they would think is stronger, six cement blocks stacked high or a board that is 6 feet long and 6 by 6?

- are the cement blocks stacked without mortar? are the cement blocks loaded in bending or compression? is the board loaded in bending or compression? What is the criterion of failure? cracking or breaking? Not a fair comparison with out some explanation.

- Q: How to install the solution of cement pressure plate

- Light keel plus cement pressure plate: Formal method: only use three light keel plus two pieces of cement pressure plate production. Light Gang keel did not make the frame, but played a connection role. This is not strong enough. But the provincial workers expected material. Formal methods: the use of light keel made of frames, after the supervision and acceptance by the Party, and then sealed cement pressure plate, linked to steel wire mesh, and finally paste the disk. Features: not easy to deformation, nowadays the most commonly used company decoration process. Plastic buckle plate, plastic aluminum plate production: These two methods for home decoration finished, and want to wrap up the riser. Because it is not necessary to fill the disk, it is convenient. Plastic buckle: wood keel plus angle, directly from the bottom of the buckle up into the installation. Disadvantages: not beautiful. Aluminum-plastic plate: wood keel on the nail nine PCT board, and then all the glue to the aluminum-plastic plate stick to a variety of colors, close to the disk effect. Disadvantages: aluminum-plastic plate angle is easy to crack, should use thicker plate.

- Q: do i need mortar under the cement board?

- no you just screw it to the wall or studs. then after its up you tape and mortar the joints with special mortar and tape. then you tile or put you tub surround up over it

- Q: the durock cement board is 1/2 inch and the drywall is 5/8 of an inch...So the shower wall is about an 1/8 of an inch recessed intothe wall. What can I do to fix the situation without redoing anymore walls. If I butt up the bullnose tile against the drywall about half of the tile's thickness sticks out...actually looks ok. I don't know if i should try to make a gradient from the drywall to the tile. There are also some gap between the two types of boards.....fill it with mortar?

- O.K. in this situation I will usually float this area , in other words the same way u float sheetrock , but I use mastic instead of gypsum compound.

- Q: Standard cement prefabricated board load capacity is a square how many kilograms, thank you

- In accordance with national standards: cast-in-place cement board bearing capacity is 250 kg / square meter, prefabricated board is 200 kg / square meter.

Send your message to us

interior board

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 120000pcs pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords