Exterior wall insulation decoration integrated board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

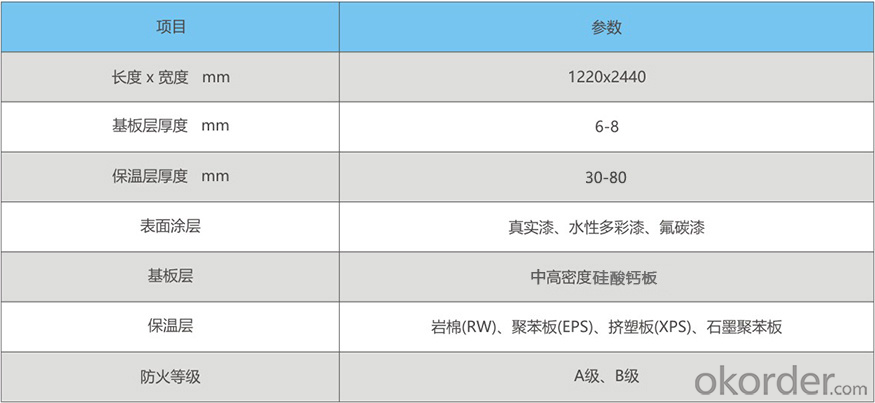

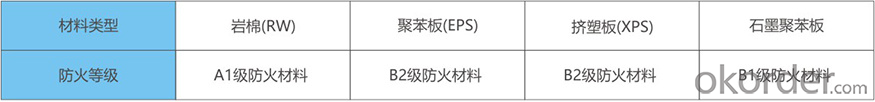

Specification

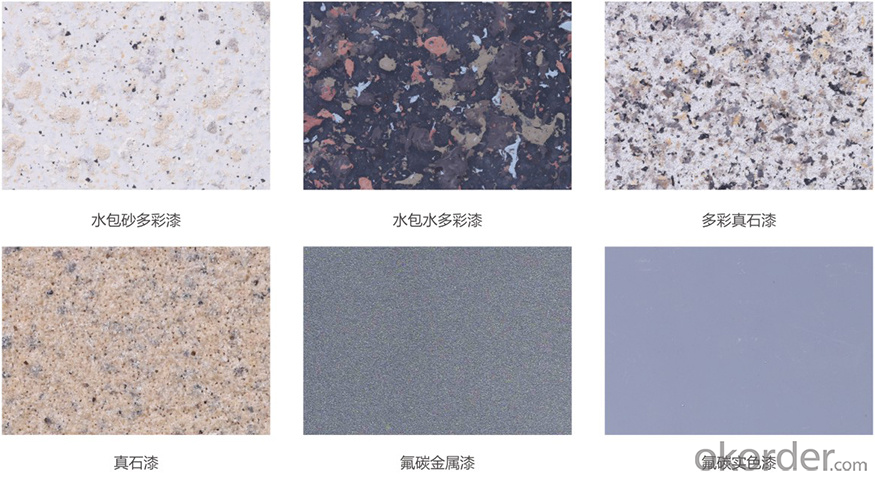

exterior wall insulation decoration integrated board is prefabricated in the factory with external wall insulation and decorative functions as one of the board, which is composed of decorative coating, substrate and insulation layer. finishing layer according to customer requirements of various colors of fluorocarbon paint, true stone paint, water-based paint, oil paint, etc., the substrate is calcium silicate board, insulation layer material using rock wool, polyurethane, graphite polystyrene board, eps, xps and other materials.

product features

the integration of exterior wall insulation decoration is installed on the outer wall of the building through the installation of anchors, with the function of thermal insulation and decoration, and with the waterproof and flame retardant, light anti-crack, sound insulation and noise reduction, green environmental protection, beautiful durability and other characteristics. in addition, because of the simple installation of the plate, can shorten the construction period, greatly save the construction cost.

product application

it is applicable to the new brick and concrete structure, frame structure, steel structure, light body room and other types of building exterior wall, but also applicable to the existing building decoration energy-saving renovation, as well as outdoor decoration.

- Q: Moisture gypsum board is not calcium calcium board?

- Silicon calcium board and gypsum board compared to the appearance of the gypsum board to retain the appearance of the weight is much lower than the gypsum board, the strength is much higher than the gypsum board to extend the service life of the material;

- Q: What is the calcium silicate board used in the bathroom ceiling

- .pvc plastic steel polymer ceiling. (Affordable, short life, difficult maintenance, moisture good)

- Q: Paper gypsum board, calcium silicate board, silicon calcium board difference

- Gypsum board is built with gypsum (that is, CaSO4) as the main raw material, mixed with the right amount of additives (adjust the rate of condensation) and fiber to do the core, with a special plate for the face, the processing of the plate. High, impatient

- Q: Calcium and calcium silicate board and calcium carbonate plate distinction and contact

- Smallpox modeling Less use of calcium silicate board. hardness. Moisture, waterproof. Deformation. Better performance on fire. 2 price is not much.

- Q: Is the calcium silicate board attached directly to the wall?

- Yes, but the premise is that the wall must have a good flatness, otherwise, after the installation of the surface will be uneven.

- Q: What is calcium silicate board?

- Part of my finishing part of the hair you see: fiber reinforced calcium silicate board (referred to as calcium silicate board) is inorganic mineral fiber or cellulose fiber and other loose fiber as a reinforcing material to calcium - siliceous material as the main cementing material , By the pulp, into the blank and high pressure steaming and other processes made of new environmentally friendly energy-saving sheet.

- Q: Calcium silicate board with what saw blade saw faster

- The Cutting stainless steel is recommended with M35 grades of high speed hacksaw. ☆ specially designed clamp, strong grip. ☆ slide automatically to the oil lubrication; automatic feeding. Make your operation safer! ☆ fast, convenient, efficient, saving labor and processing times. ☆ machine parts using imported components to ensure that the machine's life. ☆ machine power, long life, smooth and beautiful body can not wrinkle, non-technical staff can operate freely! ☆ new optimization of the overall design, small size, versatility, the body is stable without deformation. ☆ machine design structure is reasonable, solid and reliable, smooth operation. ☆ mechanical parts by strict inspection, quality, uniform specifications! ☆ fuel tank with a new generation of carbon dioxide welding, to ensure that no residual impurities in the tank, no oil, no welding slag and other undesirable phenomena. ☆ coolant automatic circulation, to ensure smooth cut, saw blade long life. ☆ sawdust concentrated treatment, convenient and clean.

- Q: Hydrate calcium silicate gel under what circumstances

- Hydrate calcium silicate gel under what circumstances

- Q: Calcium silicate board with asbestos and non-asbestos how to choose

- In the real life of the decoration of the procurement staff, some are on the building materials how to understand, especially those construction units, many of the construction of the College of Engineering materials is also a little knowledge, so that caused by the misunderstanding of building materials, On the current calcium silicate board, basically divided into two kinds, one is decorated with, and the other is the ceiling with the

- Q: Will silicon calcium plate become moldy?

- Short time water seepage, and timely drying, keep the ventilation is not mildew. If there is easy to mold the impurities inside the silicon calcium board and glue, and in the long-term humid, non-ventilated environment, it may be mildew.

Send your message to us

Exterior wall insulation decoration integrated board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches