Insulating Fire Brick - High-Quality Insulation Brick Refractory Heat Resistant Building Materials

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t

- Supply Capability:

- 2000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Insulating Brick

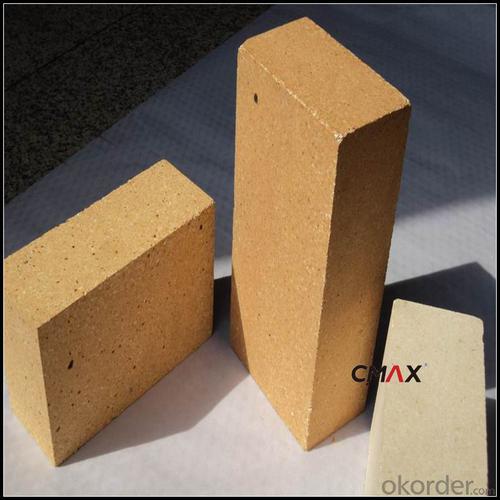

CMAX insulating firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

Refractory brick is dense shaped refractory material. With high refractoriness and mechanical behavior under high temperature, refractory brick is the necessary material of high-temperature services, mainly used for industrial furnaces and kilns and thermal equipment.

Refractory brick for blast furnace is mainly used in stack, bosh, bellly and bottom of blast furnace.

Insulating Brick Features

1.Refractory brick manufacturer

2.ISO9001:2000 certificate

3.Timely delivery and best service

Insulating Brick Application

glass industries iron & steel industries

ceramics industries non-ferrous metals industries

electrolytic Aluminum industries power generation industries

Heat surface fireproof lining other fire-proof back lining

Insulating Brick Data Sheet

Classification Temperature (℉/℃) | 3000/1650 |

Bulk Density (g/cm3 ) | ≤1.0 |

Thermal Conductivity | |

800℃, W/m.K | ≤0.39 |

1000℃, W/m.K | ≤0.43 |

1200℃, W/m.K | ≤0.48 |

Reheating Linear Change (%) | 1550℃×12h |

≤0.9 | |

Chemical Composition (%) | |

Al2O3 | ≥75 |

Fe2O3 | ≤0.5 |

Packaging & Shipping

Packaging Details:Be packed in fumigated wooden pallets

Delivery Detail: 30 days after order

Our Services

Optimum solution and product supply of refractories for high temperature industries, such as iron steel, non-ferrous, petrochemical and building materials.

Engineering design, contract and consult for refractories, and civil architecture design.

Research, development, manufacture and sale of superhard materials.

R&D, manufacture and sale of special packing materials for export.

Inspection, supervision and arbitration of refractories.

Consultation and services in refractories information.

Training and cultivation of high-level talents in refractories profession

Sales Network

Company Information

CNBM (China National Building Material) Group is the largest comprehensive building materials group in China that in integrate scientific research, manufacturing and logistics into one entity. The largest building materials and equipment specialists in China. Upon State Council approval, today CNBM owned more than 300 subordinate manufacturing factories and servicing companies. There are 6 fully owned public listed companies and 11 partially owned with substantial shares public listed companies. In many of these fields, CNBM is playing the leading role in the building industry in the country.

FAQ

1. Which products do you have?

We have all kinds of refractory brick, castable, mortar, cement, ceramic fiber products, etc.

Or you could browse our products to choose what you need.

2. Can you give me a brief introduction of the application of your products?

We are mainly specializing in the refractory materials in iron and steel, cement, glass, ceramics, petrochemical, electric power Industry, etc.

3. If I need your offer, what information do you need?

In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc. If any question, please contact us freely.

- Q: Are insulating fire bricks resistant to flame impingement?

- Yes, insulating fire bricks are resistant to flame impingement.

- Q: Are insulating fire bricks resistant to impact or mechanical stress?

- Indeed, insulating fire bricks exhibit resistance against impact and mechanical stress. These bricks are crafted using lightweight refractory materials, purposefully formulated to endure extreme temperatures and thermal shock. Their composition is specifically engineered to possess exceptional resilience against mechanical stress and impact, rendering them appropriate for a multitude of applications in which external forces or pressure may be exerted upon them. Remarkably, these bricks retain their structural integrity and durability, safeguarding their shape and thermal insulation attributes even when subjected to mechanical stress or impact. Consequently, they are highly recommended for deployment in furnaces, kilns, and other environments characterized by elevated temperatures.

- Q: Can insulating fire bricks be used in ceramic fiber blankets?

- No, insulating fire bricks cannot be used in ceramic fiber blankets. Insulating fire bricks are dense and solid, designed to provide insulation and withstand high temperatures in applications such as furnaces and kilns. On the other hand, ceramic fiber blankets are flexible and lightweight, made from ceramic fibers that provide excellent thermal insulation. They are commonly used as insulation in various industrial applications, including lining for furnaces, boilers, and high-temperature equipment. Mixing insulating fire bricks with ceramic fiber blankets would not be effective as these two materials have different properties and purposes.

- Q: Can insulating fire bricks be used in the construction of BBQ pits?

- Indeed, the utilization of insulating fire bricks is feasible for the construction of BBQ pits. These bricks are specifically engineered to endure extreme temperatures and possess exceptional heat resistance attributes, rendering them perfectly suited for BBQ pit applications. By incorporating these bricks, heat is effectively captured and evenly dispersed, leading to improved cooking efficiency and a more enjoyable BBQ experience. Moreover, the inclusion of insulating fire bricks aids in minimizing heat dissipation, guaranteeing that the BBQ pit retains and sustains heat for an extended duration. All in all, the integration of insulating fire bricks significantly enhances the overall performance and longevity of the BBQ pit.

- Q: Can insulating fire bricks be used in the construction of ceramic fiber-lined kilns?

- Indeed, the utilization of insulating fire bricks is possible for the construction of ceramic fiber-lined kilns. These specialized bricks are purposely designed to deliver exceptional insulation, rendering them ideal for situations that prioritize heat retention. By combining them with ceramic fiber lining, insulating fire bricks contribute to enhanced energy efficiency and diminished heat dissipation within kilns. Moreover, their lightweight nature and ease of handling facilitate simpler installation and construction of the kiln. Ultimately, the incorporation of insulating fire bricks in the construction of ceramic fiber-lined kilns positively impacts the kiln's overall performance and efficiency.

- Q: Can insulating fire bricks be used for insulation in heat exchangers?

- Insulation in heat exchangers can be achieved by utilizing insulating fire bricks. These bricks are constructed from a lightweight refractory material that boasts exceptional thermal insulation properties. With their low thermal conductivity, insulating fire bricks effectively minimize heat transfer between the two sides of the heat exchanger. Consequently, they aid in maintaining the desired temperature within the heat exchanger and prevent heat loss to the surroundings. Furthermore, the durability of these bricks is evident as they can endure high temperatures and thermal shocks, making them ideal for the harsh conditions typically encountered in heat exchangers. In summary, incorporating insulating fire bricks into heat exchangers not only enhances energy efficiency and reduces heat loss but also improves the overall system performance.

- Q: Are insulating fire bricks suitable for use in kilns and furnaces?

- Yes, insulating fire bricks are suitable for use in kilns and furnaces. Insulating fire bricks are designed to provide excellent thermal insulation, making them ideal for applications that require high temperatures, such as in kilns and furnaces. They have low thermal conductivity which helps to minimize heat loss and improve energy efficiency. Additionally, insulating fire bricks are lightweight and durable, allowing for easy installation and long-lasting performance in high-temperature environments. They are resistant to thermal shock and can withstand rapid temperature changes, making them a reliable choice for kilns and furnaces. Overall, insulating fire bricks are an excellent option for providing insulation and maintaining high temperatures in kilns and furnaces.

- Q: Are insulating fire bricks resistant to hydrofluoric acid vapors?

- Hydrofluoric acid vapors can cause damage to insulating fire bricks. These bricks are primarily made to handle high temperatures and offer thermal insulation. However, they are not specifically designed to withstand chemical attacks, such as those caused by hydrofluoric acid. Thus, caution should be exercised when using insulating fire bricks in environments where hydrofluoric acid vapors are present, as they may deteriorate or break down over time. Consulting with the manufacturer or a chemical engineer is recommended to identify the most suitable materials for dealing with hydrofluoric acid vapors.

- Q: Can insulating fire bricks be used in heat exchangers?

- Insulating fire bricks are indeed applicable for heat exchangers. Their design aims to provide exceptional thermal insulation, making them perfect for high-temperature scenarios like heat exchangers. These bricks are crafted from lightweight substances and possess minimal thermal conductivity, enabling them to effectively minimize heat loss or gain within the heat exchanger. Furthermore, insulating fire bricks exhibit remarkable resistance to thermal shock and can endure extreme temperatures, solidifying their reliability for heat exchanger applications. Ultimately, incorporating insulating fire bricks in heat exchangers can enhance energy efficiency and overall performance.

- Q: What is the bulk density of insulating bricks?

- Stoneware porcelain water absorption rate is greater than 0.5% and less than or equal to 3%; fine stoneware bibulous rate is greater than 3% and less than or equal to 6%; brick bibulous rate is greater than 6% and less than or equal to 10%; pottery tile water absorption rate is greater than 10%. The water absorption rate of expression: ceramic brick brick >6% = >10% = >3% = fine stoneware porcelain stoneware or porcelain >0.5%

Send your message to us

Insulating Fire Brick - High-Quality Insulation Brick Refractory Heat Resistant Building Materials

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t

- Supply Capability:

- 2000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords