Hot Rolled unequal Angle Steel used for Stiffeners

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 220000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

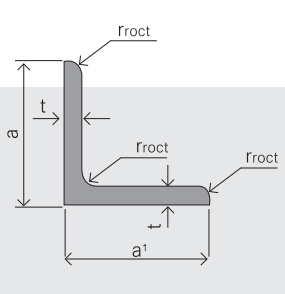

Specifications of Hot Rolled unequal Angle Steel uased for Stiffeners

1.Standards:GB,

2. Invoicing on theoretical weight or actual weight as customer request3.Material:GBQ235B,Q345BorEquivalent;ASTMA36;EN10025.

4. Payment terms:

1).100% irrevocable L/C at sight.

2).35% T/T prepaid and the balance against the copy of B/L.

3).35% T/T prepaid and the balance against L/C

5.Sizes:

EQUAL ANGLES SIZES |

| ||

a(mm) | a1(mm) | thickness(mm) | length |

50 | 50 | 3.7---6.0 | 6M/9M/12M |

60 | 60 | 5.0---6.0 | 6M/9M/12M |

70 | 70 | 6.0---7.0 | 6M/9M/12M |

75 | 75 | 5.0---10.0 | 6M/9M/12M |

80 | 80 | 6.0---10.0 | 6M/9M/12M |

100 | 100 | 6.0---12.0 | 6M/9M/12M |

120 | 120 | 8.0-12.0 | 6M/9M/12M |

125 | 125 | 8.0---12.0 | 6M/9M/12M |

130 | 130 | 9.0-12.0 | 6M/9M/12M |

140 | 140 | 10.0-16.0 | 6M/9M/12M |

150 | 150 | 10---15 | 6M/9M/12M |

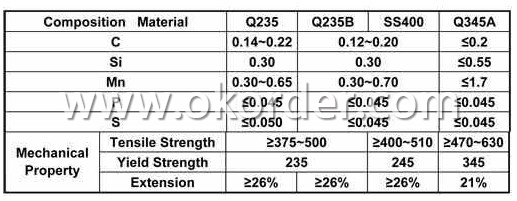

6. Material details:

Usage & Applications Hot Rolled Angle Steel

According to the needs of different structures, Angle can compose to different force support component. It is widely used in various building structures and engineering structures such as ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Packaging & Delivery

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 30MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and 20 feet and 40 feet container, or by bulk cargo, also we could do as customer's request.

- Q: Are steel angles affected by creep?

- Yes, steel angles are indeed affected by creep. Creep is a phenomenon where materials, including steel, deform over time under a constant load or stress. Steel angles, being structural components, are subjected to various loads and stresses, especially if they are part of long-term applications such as bridges or buildings. Over time, the sustained stress can cause the steel angles to gradually deform, leading to creep. Therefore, it is essential to consider creep effects when designing structures that incorporate steel angles to ensure long-term structural integrity.

- Q: What is the maximum length of a continuous steel angle?

- Several factors determine the maximum length of a continuous steel angle, including its size, weight, transportation and handling limitations. Typically, the maximum length is restricted to what can be safely transported and handled by equipment like cranes or forklifts. This limit can vary based on the capabilities of the equipment and any transportation restrictions. The manufacturing process may also limit the length, as longer angles may be more challenging to produce or require specialized equipment. Ultimately, the maximum length should be determined based on the project's specific requirements and constraints, taking into account these factors.

- Q: What are the limitations of using steel angles in high-temperature applications?

- The susceptibility of steel angles to thermal expansion is one limitation when using them in high-temperature applications. Similar to other materials, steel expands when heated and contracts when cooled. This characteristic can cause dimensional changes in the steel angles, potentially impacting their structural integrity and performance. Another limitation is the potential weakening of steel angles at elevated temperatures. As the temperature rises, the steel can undergo tempering, a process that reduces its hardness and increases its ductility. This can result in reduced load-bearing capacity and increased vulnerability to deformation or failure under high loads or stresses. Furthermore, steel angles are prone to oxidation and corrosion at high temperatures. When exposed to oxygen and moisture in the air, steel can form rust or iron oxide. This can weaken the steel angles and compromise their structural integrity, especially in environments with high humidity or aggressive chemical agents. In addition, steel angles may experience creep when subjected to high temperatures and constant loads. Creep refers to the gradual deformation or elongation of a material under constant stress over time. This can lead to permanent deformation and jeopardize the structural stability of the steel angles. Lastly, the thermal conductivity of steel must be carefully considered in the design and fabrication of steel angles for high-temperature applications. Steel has relatively high thermal conductivity, meaning it can quickly transfer heat. This characteristic can result in uneven heating and cooling of the steel angles, potentially causing stress concentrations or thermal gradients that could impact their performance. Given these limitations, it is crucial to thoroughly assess the suitability of steel angles for high-temperature applications and explore alternative materials or design adjustments to ensure optimal performance and safety.

- Q: Are steel angles suitable for high-temperature environments?

- No, steel angles are not suitable for high-temperature environments as they tend to lose their structural integrity and strength at elevated temperatures.

- Q: Are steel angles suitable for mezzanine floor construction?

- Indeed, steel angles prove to be suitable for the construction of mezzanine floors. Mezzanine floor construction commonly incorporates steel angles due to their robustness and long-lasting nature. They offer exceptional support and stability, thereby making them an ideal choice for bearing the weight of the mezzanine floor and any additional loads placed upon it. By simply bolting or welding steel angles together, a sturdy framework can be easily created for the mezzanine floor. Moreover, steel angles can be tailored to meet specific design requirements, thereby allowing for flexibility in mezzanine floor construction. In summary, steel angles provide a dependable and cost-effective solution for the construction of mezzanine floors.

- Q: Are steel angles available in non-standard dimensions?

- Steel angles in non-standard dimensions can be obtained. Although standard steel angles are typically manufactured in specific sizes, such as 2x2 inches or 3x3 inches, there are manufacturers and suppliers capable of producing steel angles in custom sizes to fulfill specific project requirements. These custom sizes may involve varying leg lengths, thicknesses, or overall dimensions that are not commonly found in standard steel angles. Achieving the desired dimensions can be accomplished through processes like cutting, bending, and welding when fabricating custom steel angles. Nevertheless, it is important to consider that non-standard dimensions may result in additional time and cost for production compared to readily available standard sizes.

- Q: What are the common standards and specifications for steel angles?

- The common standards and specifications for steel angles include the American Society for Testing and Materials (ASTM) A36/A36M, which covers carbon structural steel shapes, and ASTM A572/A572M, which pertains to high-strength low-alloy structural steel angles. Additionally, the European Norm (EN) 10025-2 specifies the technical delivery conditions for non-alloy structural steels, including angles. These standards define the chemical composition, mechanical properties, and tolerances of steel angles, allowing for consistent quality and compatibility in various construction and engineering applications.

- Q: What are the environmental impact considerations of using steel angles?

- The use of steel angles in various industries does have environmental impact considerations that need to be taken into account. One major consideration is the extraction and processing of iron ore to produce steel. The mining of iron ore can have significant environmental impacts, including habitat destruction, soil erosion, and water pollution. Additionally, the extraction process requires large amounts of energy, contributing to greenhouse gas emissions and air pollution. Furthermore, the production of steel involves the use of coal and other fossil fuels, which also contribute to greenhouse gas emissions. The burning of these fuels releases carbon dioxide and other pollutants, leading to climate change and air pollution. Steel production also generates a significant amount of waste, including slag and other byproducts. Proper disposal and management of these waste materials are crucial to minimize their impact on the environment. Transportation and logistics also play a role in the environmental impact of using steel angles. The transportation of steel products from manufacturing facilities to construction sites or other end-users can contribute to carbon emissions, especially if long distances are involved. However, it is worth noting that steel is a highly durable material with a long lifespan. This longevity can offset some of the environmental impacts associated with its production and transportation. To minimize the environmental impact of using steel angles, several strategies can be employed. Firstly, using recycled steel reduces the need for extracting new iron ore and decreases energy consumption and emissions. Incorporating recycled content into steel production is an effective way to reduce the environmental footprint. Additionally, improving energy efficiency in steel manufacturing processes can help reduce greenhouse gas emissions. Adopting cleaner technologies, such as electric arc furnaces, can significantly reduce carbon emissions compared to traditional blast furnace methods. Furthermore, sustainable transportation practices, such as utilizing efficient shipping methods or promoting local sourcing, can help reduce the carbon footprint associated with the transportation of steel angles. Overall, while the use of steel angles does have environmental impact considerations, implementing sustainable practices can mitigate these impacts and contribute to a more environmentally friendly industry.

- Q: What is the typical size range for steel angles?

- Steel angles can vary in size depending on the application and industry. Generally, they are available in widths ranging from 20 to 200 millimeters (mm) and thicknesses ranging from 3 to 20 mm. The length of steel angles can also vary, typically ranging from 3 to 12 meters. These dimensions allow for a wide range of applications, including structural support in construction, machinery manufacturing, and architectural uses. It is worth mentioning that while these size ranges are common, there may be variations and custom sizes available based on specific project requirements.

- Q: What is the process of galvanizing steel angles?

- The process of galvanizing steel angles involves immersing the angles in a bath of molten zinc. This helps to protect the steel from corrosion and increases its longevity. The angles are first cleaned to remove any dirt or grease, then they are dipped into a pre-treatment solution to prepare the surface for galvanization. Next, the angles are immersed in the molten zinc bath, where a metallurgical reaction takes place, resulting in a layer of zinc coating on the steel. Finally, the angles are cooled and inspected for quality before being ready for use.

Send your message to us

Hot Rolled unequal Angle Steel used for Stiffeners

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 220000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords