Hot Rolled unequal Angle Steel for Bridge Girder Framework

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

Specifications of Hot Rolled unequal Angle Steel for Bridge Girder Framework

1.Standards:GB,ASTM,BS,AISI,DIN,JIS

2. Invoicing on theoretical weight or actual weight as customer request3.Material:GBQ235B,Q345BorEquivalent;ASTMA36;EN10025,S235JR.

4. Payment terms:

1).100% irrevocable L/C at sight.

2).20% T/T prepaid and the balance against the copy of B/L.

3).20% T/T prepaid and the balance against L/C

5.Sizes:

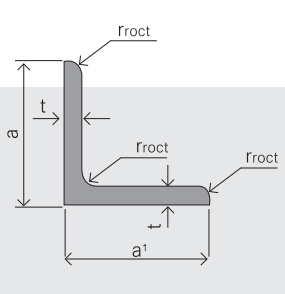

EQUAL ANGLES SIZES |

| ||

a(mm) | a1(mm) | thickness(mm) | length |

75 | 75 | 5.0---10.0 | 6M/9M/12M |

80 | 80 | 6.0---10.0 | 6M/9M/12M |

100 | 100 | 6.0---12.0 | 6M/9M/12M |

120 | 120 | 8.0-12.0 | 6M/9M/12M |

130 | 130 | 9.0-12.0 | 6M/9M/12M |

140 | 140 | 10.0-16.0 | 6M/9M/12M |

150 | 150 | 10---15 | 6M/9M/12M |

160 | 160 | 10---16 | 6M/9M/12M |

180 | 180 | 12---18 | 6M/9M/12M |

200 | 200 | 14---20 | 6M/9M/12M |

Usage & Applications Hot Rolled Angle Steel

According to the needs of different structures, Angle can compose to different force support component. It is widely used in various building structures and engineering structures such as roof beams, hoisting machinery and transport machinery, ships, container frame and warehouse etc.

Packaging & Delivery of Hot Rolled unequal Angle Steel for Bridge Girder Framework

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 35MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in container, or by bulk cargo, also we could do as customer's request.

- Q: Can steel angles be used for wall bracing?

- Indeed, wall bracing can make use of steel angles. These angles are frequently employed in construction to offer structural support and reinforcement. Their primary function is to fortify walls and ensure the overall stability of the edifice. Owing to their robustness and longevity, steel angles are a highly suitable option for wall bracing purposes. Furthermore, their fabrication and installation are straightforward, rendering them a cost-efficient solution for wall bracing requirements.

- Q: Are steel angles suitable for architectural applications?

- Yes, steel angles are suitable for architectural applications. They are commonly used in construction projects to provide structural support, such as in building frames, facades, and bridges. Steel angles offer excellent strength and durability, making them a reliable choice for architects seeking a versatile and long-lasting material for their designs.

- Q: What are the common design codes and standards for steel angles?

- The specific application and industry requirements determine the common design codes and standards for steel angles. Various recognized design codes and standards are applicable to steel angles, including: 1. The American Institute of Steel Construction (AISC) offers design specifications and standards for structural steel construction, including angles. The AISC Steel Construction Manual provides guidance on designing steel structures and selecting steel angles. 2. The American Society for Testing and Materials (ASTM) develops and publishes technical standards for different materials, including steel. ASTM A36/A36M is a commonly referenced standard for carbon structural steel, including angles. It specifies requirements for chemical composition, mechanical properties, and testing methods. 3. The European Norm (EN) specifies technical delivery conditions for structural steel products. EN 10025-2 covers non-alloy structural steels, including angles, and provides requirements for chemical composition, mechanical properties, and tolerances. 4. The British Standards Institution (BSI) publishes standards related to steel angles, such as BS EN 10056-1. This standard details the dimensions and tolerances for hot-rolled equal and unequal steel angles. 5. The Canadian Standards Association (CSA) provides guidance for steel design and construction in Canada. CSA G40.21 is a widely used standard that covers requirements for general structural steel, including angles. It is important to note that these examples represent common design codes and standards for steel angles. Depending on the project and location, additional local or industry-specific codes and standards may need to be considered. Consulting a structural engineer or referring to relevant design codes and standards is crucial for ensuring compliance and safety in steel angle design and construction.

- Q: Are steel angles suitable for manufacturing support brackets for pipes?

- Yes, steel angles are suitable for manufacturing support brackets for pipes. Steel angles are known for their strength and durability, making them an ideal material for supporting heavy loads such as pipes. They provide excellent structural support and can withstand the weight and pressure exerted by pipes. Additionally, steel angles are resistant to corrosion, which is crucial when dealing with pipes that may come into contact with moisture or chemicals. Their versatility allows for various design options, making it easier to customize support brackets to fit specific pipe sizes and configurations. Overall, steel angles are a reliable and practical choice for manufacturing support brackets for pipes.

- Q: What are the different types of steel angles connections for trusses?

- For trusses, there exists a variety of steel angle connections, each with its own advantages and applications. 1. Bolted Connections: These connections, widely used for trusses, involve joining the steel angles together using bolts. They offer a secure and robust connection, while also being easy to install and disassemble if necessary. Bolted connections are often employed in situations where trusses need to be transported or assembled on-site with convenience. 2. Welded Connections: This type of connection involves fusing the steel angles together using heat and pressure, resulting in a permanent and strong connection. Welded connections are particularly suitable for heavy-duty truss applications, offering excellent load-bearing capacity. They are commonly utilized in structures that require high strength and rigidity. 3. Gusset Plate Connections: In this method, a gusset plate, made of steel, is employed to connect the steel angles together. The gusset plate is usually bolted or welded to the steel angles, providing a secure connection. This type of connection is commonly utilized when the angles need to be connected at angles other than 90 degrees. 4. Clip Connections: Clip connections utilize metal clips to join the steel angles together. These clips are typically bolted or welded to the steel angles, creating a strong and secure connection. Clip connections are often used for trusses that require a flush connection at a 90-degree angle. 5. Cleat Connections: Cleat connections involve the use of a metal plate, called a cleat, to connect the steel angles together. The cleat is typically bolted or welded to the steel angles, providing a sturdy connection. Cleat connections are commonly used for trusses that require additional reinforcement and a 90-degree angle connection. In conclusion, the selection of a steel angle connection for trusses depends on the specific requirements of the structure, such as load-bearing capacity, ease of installation, and desired strength and rigidity. To determine the most suitable connection type for a particular application, it is recommended to consult with a structural engineer or truss manufacturer.

- Q: Can steel angles be used for framing windows?

- Yes, steel angles can be used for framing windows. They are commonly used in construction as a structural element for window frames due to their strength, durability, and ability to support heavy loads.

- Q: Can steel angles be bent or shaped?

- Steel angles, indeed, possess the capability to be bent or molded to desired forms. Typically, they are crafted from hot-rolled steel and find extensive usage in the realms of construction and manufacturing. These angles are known for their versatility, as they can be effortlessly bent or shaped to meet specific design prerequisites. The process of bending steel angles encompasses the application of force onto the metal, thereby causing it to undergo deformation and assume a novel configuration. This can be achieved through manifold techniques, such as utilizing specialized machinery like a press brake or by subjecting the steel to heat to render it malleable before bending. The pliability of steel angles in terms of bending or shaping endows them with immense adaptability, enabling their utilization in a diverse array of applications and bestowing greater flexibility upon design and construction endeavors.

- Q: Are steel angles vulnerable to rusting?

- Yes, steel angles are vulnerable to rusting as they are made of steel, which is prone to corrosion when exposed to moisture and oxygen.

- Q: How do you calculate the buckling capacity of a steel angle?

- The buckling capacity of a steel angle can be calculated using the Euler's formula, which takes into account the properties of the steel angle section, such as its length, moment of inertia, and modulus of elasticity. By applying this formula, the critical buckling load of the steel angle can be determined, giving an estimate of its buckling capacity.

- Q: Double angle steel rod in the corners of the roof steel why need to set the plate?

- A rod is a member of a much larger dimension than a horizontal (vertical) direction. The beams, columns and other components in the building are generally abstracted as rods. The shape and size of the rod can be described by two major geometric elements, the cross section and the axis of the rod. A cross section is a vertical section perpendicular to the length of the bar, and the axis is the center of each cross section. The cross section and the axis of the rod are perpendicular to each other. A rod with the same axis and straight line and cross section is called a straight rod with equal section. Building mechanics and mechanics of materials are mainly concerned with equal section straight bars. The bar whose cross section changes along the axis is called a cross section bar.

Send your message to us

Hot Rolled unequal Angle Steel for Bridge Girder Framework

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords