Hot Rolled unequal Angle Steel for High Voltage Transmission Tower

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

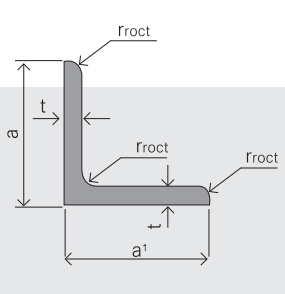

Specifications of Hot Rolled unequal Angle Steel for High Voltage Transmission Tower

1.Standards:GB,ASTM,

2. Invoicing on theoretical weight or actual weight as customer request3.Material:GBQ235B or Equivalent;ASTMA36;EN10025,S235JR.

3. Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

4.Sizes:

EQUAL ANGLES SIZES |

| ||

a(mm) | a1(mm) | thickness(mm) | length |

100 | 100 | 6.0---12.0 | 6M/9M/12M |

120 | 120 | 8.0-12.0 | 6M/9M/12M |

130 | 130 | 9.0-12.0 | 6M/9M/12M |

140 | 140 | 10.0-16.0 | 6M/9M/12M |

150 | 150 | 10---15 | 6M/9M/12M |

160 | 160 | 10---16 | 6M/9M/12M |

180 | 180 | 12---18 | 6M/9M/12M |

200 | 200 | 14---20 | 6M/9M/12M |

Usage & Applications Hot Rolled Angle Steel

According to the needs of different structures, Angle can compose to different force support component. It is widely used in various building structures and engineering structures such as roof beams, hoisting machinery and transport machinery, ships, container frame and warehouse etc.

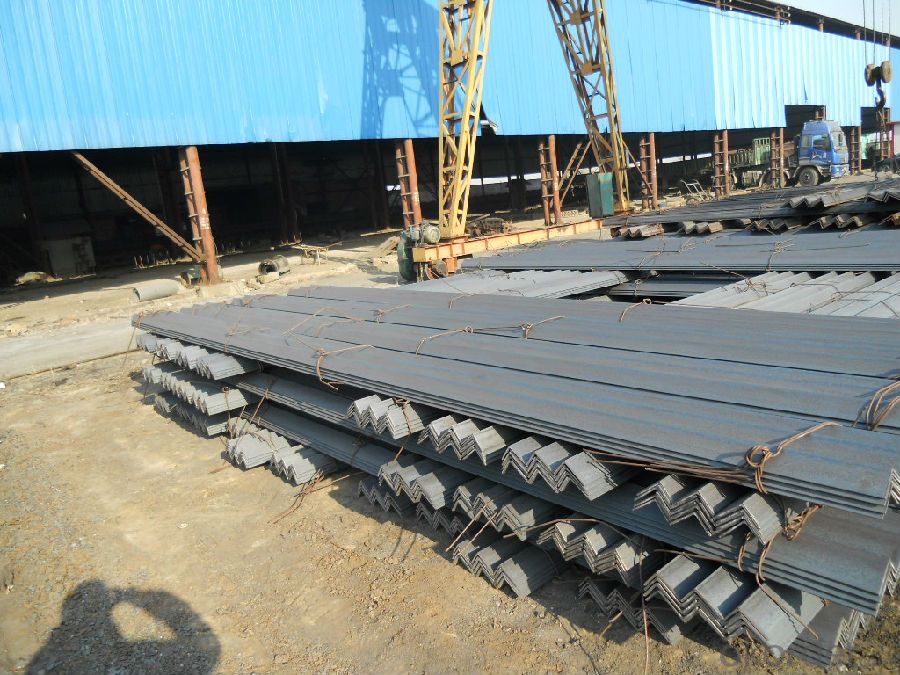

Packaging & Delivery of Hot Rolled unequal Angle Steel for High Voltage Transmission Tower

1. Transportation: the goods are delivered by truck from mill to loading port, the transportation cost per ton will be little higher than full load.

2. With bundles and load in container, or by bulk cargo, also we could do as customer's request.

- Q: What is the maximum load capacity of a steel angle?

- The maximum load capacity of a steel angle depends on various factors such as the dimensions, thickness, grade, and quality of the steel used. Generally, steel angles are designed to withstand significant loads due to their structural nature. However, it is important to consult engineering specifications and relevant building codes to determine the specific maximum load capacity of a steel angle in a given application. The load capacity is typically calculated by considering the angle's cross-sectional area, the material's yield strength, and the applied load factors. Additionally, factors such as the angle's length, support conditions, and the presence of any additional reinforcement or bracing can also influence the maximum load capacity. It is crucial to ensure that the steel angle is properly selected, designed, and installed to safely support the intended loads and meet the required structural standards.

- Q: Can steel angles be used for structural applications?

- Indeed, structural applications can make use of steel angles. Due to their strength, durability, and versatility, steel angles are frequently employed in construction and engineering endeavors. The convenience of welding, bolting, or otherwise connecting them to other steel components makes them particularly valuable for providing structural support and stability. Frames, supports, braces, and reinforcements often incorporate steel angles. Moreover, their shape and design enable efficient load-bearing capabilities, rendering them suitable for a wide range of structural applications including bridges, buildings, towers, and industrial structures. In summary, steel angles present a dependable and budget-friendly option for structural applications.

- Q: Can steel angles be used for manufacturing safety barriers?

- Indeed, safety barriers can be manufactured using steel angles. In construction projects, steel angles are frequently utilized owing to their robustness and longevity. Specifically for safety barriers, they offer a firm framework that can endure impacts and offer protection. By welding or bolting steel angles together, a solid and secure barrier can be created effortlessly. Furthermore, by galvanizing or coating steel angles with anti-corrosive substances, their lifespan and resistance against environmental factors can be enhanced. In summary, steel angles are an exceptional option for manufacturing safety barriers due to their strength, durability, and versatility.

- Q: How do you protect steel angles during transportation?

- To ensure the safety and prevent damage of steel angles during transportation, there are several measures that can be taken. Firstly, it is crucial to package the steel angles securely in a manner that reduces movement and eliminates direct contact with other objects that could cause scratches or dents. This can be achieved by utilizing suitable packaging materials like protective films, foam padding, or cardboard sheets. Furthermore, proper stacking and arrangement of the angles in the transportation vehicle is essential to avoid shifting during transit. They should be placed on a stable and level surface, and if multiple layers are required, interlayer materials such as wooden boards can be utilized to provide stability and distribute the weight evenly. Considering the climate conditions during transportation is also vital. If the steel angles are being transported in an open vehicle, they must be adequately covered with waterproof tarpaulins to protect against rain, snow, or other weather elements. Even if the angles are being transported in a closed vehicle, it is still important to ensure proper ventilation to prevent condensation and the formation of rust. Lastly, careful handling and proper loading/unloading procedures are crucial to safeguard the steel angles from impacts and accidents. The use of appropriate lifting and handling equipment, such as cranes or forklifts, should be implemented to minimize any potential damage during these processes. By adhering to these protective measures, the steel angles can be safeguarded during transportation, ensuring they reach their destination in optimal condition, ready for use or further processing.

- Q: Can steel angles be used in sports facilities or stadium constructions?

- Yes, steel angles can be used in sports facilities or stadium constructions. Steel angles are commonly used in construction projects due to their strength and durability. They can be used to provide support and stability in various structural elements, such as beams, columns, and frames, making them suitable for use in sports facilities or stadium constructions where robustness and reliability are crucial.

- Q: What are the design considerations when using steel angles?

- When using steel angles in design, several considerations should be kept in mind. Firstly, the load-bearing capacity of the angles needs to be determined, considering factors such as the type and magnitude of the loads, as well as the desired safety factor. The dimensions and thickness of the angles should be chosen accordingly to ensure structural stability and prevent failure. Additionally, the connections and fasteners used to join the angles with other components should be carefully evaluated to ensure proper load transfer and minimize any potential weak points. Proper corrosion protection measures should also be incorporated to prevent rust and deterioration. Finally, factors like cost, availability, and aesthetic requirements may influence the selection of steel angles for a particular design project.

- Q: How do steel angles perform in terms of fire resistance?

- Steel angles have good fire resistance properties due to their high melting point and low thermal conductivity. They can withstand high temperatures for a longer time compared to other materials, such as wood or aluminum. However, it is important to note that the fire resistance of steel angles can be affected by factors such as the thickness of the steel, fire protection measures, and the duration of exposure to fire.

- Q: What are the environmental impact considerations of using steel angles?

- The environmental impact considerations of using steel angles include the extraction and processing of raw materials, such as iron ore and coal, which contribute to deforestation, habitat destruction, and air pollution. Steel production also requires large amounts of energy, leading to greenhouse gas emissions and climate change. Additionally, the transportation and disposal of steel angles can further contribute to carbon emissions and waste generation. However, steel angles have a long lifespan and can be recycled, reducing the need for new production and minimizing their overall environmental impact.

- Q: How do you determine the center of gravity for a steel angle?

- The center of gravity for a steel angle can be determined by finding the point where the weight of the angle is evenly distributed. This can be done by balancing the angle on a pivot point or by using mathematical calculations based on the dimensions and weight distribution of the angle.

- Q: Are steel angles suitable for manufacturing support brackets for HVAC systems?

- Indeed, steel angles prove to be fitting for the production of support brackets designed for HVAC systems. Renowned for their robustness, longevity, and ability to withstand corrosion, steel angles present an ideal choice for deployment in support brackets. They afford the essential structural reinforcement required to bear the weight of HVAC components and guarantee stability. Furthermore, steel angles allow for effortless fabrication and customization to fulfill exact bracket design specifications. Their versatility and cost-effectiveness contribute to their widespread preference in the manufacturing of support brackets for HVAC systems.

Send your message to us

Hot Rolled unequal Angle Steel for High Voltage Transmission Tower

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords