Hot Rolled Steel Plate SS400 Thickness 4.0MM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

DESCRIPTION:

GRADE: SS400, ASTM A36, A572, ST37,ST52, Q195, Q215, Q235,Q345, S235JR etc.

STANDARD: GB/T709-2006, ASTM A36, JIS G3101, DIN EN 10025, SAE 1045, ASTM A570

SPEC: 1)Width: 600-2500mm or 1000,1050,1250,1500,1800,2000mm

2)Thickness:1.5mm-200mm or as customers’ special requirements;

3)Length: 2-12m or as customers’ special requirements

FEATURES OF STEEL COILS

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

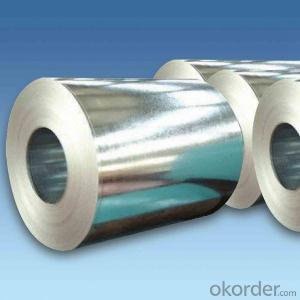

DETAILED PICTURES FOR STEEL COILS

FAQ:

Q:Do you have OEM service?

A: Yes.Variety of products size,quality and quantity can be customized according to your need.

Q:Could you support free sample?

A:Yes.We can supply FREE samples.But the delivery charges will be covered by our customers.

Q:How about the delivery time?

A:Within 15-30days after receiving the deposit or L/C at sight.

- Q: What are the limitations of using steel sheets?

- One limitation of using steel sheets is their susceptibility to corrosion, especially when exposed to moisture or certain chemicals. Additionally, steel sheets can be heavy and require special equipment for handling and installation. They also have limited flexibility and may crack or break under excessive stress or bending. Moreover, steel sheets may be more expensive compared to other materials, making them less cost-effective in certain applications.

- Q: What are the safety precautions when handling steel sheets?

- When handling steel sheets, some important safety precautions include wearing appropriate personal protective equipment such as gloves, safety glasses, and steel-toed shoes to protect against cuts and injuries. It is necessary to lift and carry steel sheets properly using correct lifting techniques and equipment to avoid strain or back injuries. Additionally, ensuring a clean and organized work area, free from any tripping hazards, is essential. Proper storage and stacking of steel sheets is crucial to prevent them from falling or shifting, causing accidents. Regular inspection and maintenance of equipment used for handling steel sheets is also important to ensure safe operation.

- Q: What is the process of laminating steel sheets?

- The process of laminating steel sheets involves bonding multiple layers of steel together to create a stronger and more durable material. This is typically done by applying heat and pressure to the sheets, which causes them to fuse together. The sheets are often coated with a layer of adhesive or resin before lamination to enhance the bonding process. The result is a laminated steel sheet that exhibits improved strength, resistance to corrosion, and other desirable properties.

- Q: Can steel sheets be customized in terms of thickness?

- Indeed, thickness customization is possible for steel sheets. Steel sheets are produced in a variety of thicknesses to accommodate diverse applications and demands. The manufacturing process allows for the customization of a steel sheet's thickness based on the customer's specific requirements. This customization feature provides versatility and adaptability, enabling steel sheets to be utilized across a broad spectrum of industries such as construction, automotive, manufacturing, and fabrication. By tailoring the thickness of steel sheets, they can effectively fulfill the precise needs for strength, durability, and structural integrity in any given project.

- Q: What is the average bending radius for steel sheets?

- The bending radius of steel sheets is subject to variation depending on factors such as thickness, grade, and steel type. Nevertheless, in the case of mild steel sheets, the minimum bending radius typically equates to roughly four times the sheet thickness. To illustrate, if the sheet thickness measures 1.6mm, the minimum bending radius would be approximately 6.4mm. It is crucial to recognize that this serves as a general principle, and particular bending specifications may deviate depending on the intended application and desired result.

- Q: What is the process of powder coating steel sheets?

- The process of powder coating steel sheets involves several steps. First, the steel sheets are cleaned and pre-treated to remove any dirt, grease, or rust. This is usually done through a combination of chemical cleaning and sandblasting. Next, the sheets are coated with a layer of electrostatically charged powder. The powder adheres to the steel sheets due to the opposite charges. After coating, the sheets are cured in an oven at high temperatures, typically around 400 degrees Fahrenheit. During this curing process, the powder melts and fuses onto the steel, creating a smooth and durable finish. Finally, the coated steel sheets are inspected for quality and packaged for shipping or further processing.

- Q: Can steel sheets withstand extreme weather conditions?

- Indeed, steel sheets are engineered to endure even the harshest weather conditions. Renowned for its robustness and durability, steel proves to be an optimal substance for withstanding the unforgiving forces of nature, including fierce winds, torrential rain, heavy snowfall, and extreme temperatures. Frequently employed in construction, roofing, and outdoor applications, steel sheets are constantly exposed to diverse weather phenomena. Moreover, these sheets can be covered with protective coatings like galvanized or painted finishes, further fortifying their resistance against corrosion and weathering. Ultimately, steel sheets exhibit remarkable reliability, enduring severe weather conditions with minimal harm or deterioration.

- Q: What are the different sheet metal joining techniques for steel sheets?

- Steel sheets can be joined using various techniques. Welding is commonly used, where the edges of the sheets are melted and fused together using heat and pressure. Different welding techniques like arc, spot, or laser welding can be used depending on the requirements. Riveting is another method, involving the use of metal fasteners called rivets. Holes are drilled in the sheets, and the rivets are inserted and deformed to secure the joint. This technique is suitable for structural applications due to its strength and durability. Bolting involves using bolts and nuts to connect the sheets. Holes are drilled, and bolts are inserted through them, with nuts tightened on the other side. Bolting allows for easy disassembly and reassembly, making it suitable for applications requiring frequent maintenance or repairs. Adhesive bonding is a technique where a strong glue is used to bond the sheets. The adhesive is applied between the surfaces, and pressure is applied for proper bonding. This method provides a clean and aesthetically pleasing joint without the need for drilling holes or using fasteners. Clinching is a cost-effective and quick method for joining steel sheets. It involves deforming the sheets using a punch and die, creating a mechanical interlock. This technique does not require additional materials and is suitable for various applications. The choice of joining technique depends on factors such as the specific application, required strength, durability, cost, and ease of assembly. Each technique has its own advantages and limitations.

- Q: Are steel sheets suitable for architectural roofing?

- Yes, steel sheets are suitable for architectural roofing. Steel sheets offer durability, strength, and longevity, making them a popular choice for architectural roofing applications. They can withstand harsh weather conditions, provide excellent protection against elements like rain, snow, and sunlight, and are available in a variety of designs and finishes to enhance the aesthetic appeal of a building. Additionally, steel sheets are lightweight, which reduces the overall load on the structure, and they are also fire-resistant, making them a reliable choice for architectural roofing.

- Q: Can steel sheets be used for reinforcing concrete structures?

- Yes, steel sheets can be used for reinforcing concrete structures. They are commonly used as reinforcement in concrete construction due to their high strength, durability, and ability to withstand high loads and provide structural support. Steel sheets are often used to reinforce concrete walls, slabs, beams, and columns, enhancing the overall strength and stability of the structure.

Send your message to us

Hot Rolled Steel Plate SS400 Thickness 4.0MM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords