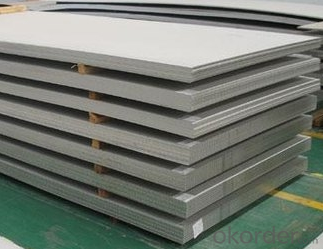

Hot Rolled Carbon Steel Plate,Carbon Steel Sheet CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Standard: | AISI, ASTM, DIN, GB, JIS | Grade: | A572,A573,A633,A678,A709,A710,G3101,G3136,etc | Thickness: | 1mm-200mm |

| Brand Name: | SHOU GANG GROUP, AN STEEL | Model Number: | Q235 | ||

| Type: | Steel Plate | Technique: | Hot Rolled | Surface Treatment: | Coated |

| Application: | widely | Special Use: | High-strength Steel Plate | Width: | 1000mm-3000mm |

| Length: | 1000mm-12000mm | Price Term: | FOB CIF CFR |

Packaging & Delivery

| Packaging Details: | standard seaworthy export packing or as the request of customers |

| Delivery Detail: | 10 days after deposit or according to customers' quantity |

Specifications

hot rolled carbon steel sheet

1.Thickness:1mm-200mm

2.Length:1000mm-12000mm

3.Width:1000mm-2000mm

hot rolled carbon steel sheet

| Product | HR steel plate prices carbon steel plate prices per kg |

| MOQ | 25 ton |

| Thickness | 1mm-200mm |

| Width | 1000mm-3000mm |

| Length | 1000mm-12000mm |

| Application | widely |

| Standard | AISI,ASTM,BS,DIN,JIS,GB,etc |

| Grade | A572,A573,A633,A678,A709,A710,G3101,G3136,etc |

| Tpye | Steel plate |

| Surfacing | Coated |

| Productive Technology | Hot Rolled & Cold Rolled |

| Port | |

| Payment Terms | L/C,T/T,Western Union,MoneyGram |

| Product Ability | 5000 tons per month |

| Delivery | 10 days after deposit or according to customers' quantity |

| Packing | standard seaworthy export packing or as the request of customers |

- Q: What is the difference between a hot rolled and hot dipped galvanized steel sheet?

- A hot rolled steel sheet is produced by rolling the steel at high temperatures, typically above 1,000 degrees Fahrenheit. This process allows the steel to be shaped and formed easily, resulting in a sheet with a rougher and less precise surface finish. Hot rolled steel sheets are commonly used in applications where strength and durability are key factors, such as in construction and structural projects. On the other hand, a hot dipped galvanized steel sheet goes through an additional process after being hot rolled. The steel sheet is immersed in a bath of molten zinc, which creates a protective coating on the surface of the steel. This coating provides excellent corrosion resistance and helps to prevent rusting, making hot dipped galvanized steel sheets ideal for outdoor and exposed applications. The main difference between the two types of steel sheets lies in their surface finish and protective properties. While hot rolled steel sheets have a rougher surface, hot dipped galvanized steel sheets have a smoother and more uniform appearance due to the zinc coating. Additionally, the galvanization process provides enhanced corrosion protection to the steel, extending its lifespan and making it suitable for harsh environments. In summary, hot rolled steel sheets are versatile and commonly used in various applications, while hot dipped galvanized steel sheets offer added protection against corrosion and are often preferred for outdoor or exposed applications.

- Q: Can steel sheets be welded or joined together?

- Indeed, it is possible to weld or join steel sheets together. The process of welding is widely employed to achieve this purpose. It entails the melting of the sheet edges, followed by their subsequent cooling and solidification. This results in a robust connection between the two sheets. Welding proves to be an efficient means of joining steel sheets due to its ability to withstand substantial levels of stress and load. Moreover, depending on the specific needs and application, alternative techniques like riveting, bolting, and adhesive bonding can also be utilized to join steel sheets.

- Q: Can steel sheets be used for roofing purposes?

- Yes, steel sheets can be used for roofing purposes. Steel is a durable and long-lasting material that is resistant to corrosion, making it an excellent choice for roofing. Steel sheets provide strength and stability to the roof, protecting the building from various weather conditions. Additionally, steel roofs are low maintenance and can be energy-efficient if properly insulated.

- Q: What are the common sizes of steel sheets available?

- Common sizes of steel sheets available include 4x8 feet, 4x10 feet, and 5x10 feet. Other sizes may also be available depending on the supplier and specific requirements.

- Q: How do steel sheets perform in abrasive environments?

- Due to their exceptional strength and durability, steel sheets excel in harsh environments that are known for causing abrasion. The resilience of steel, owing to its hardness, enables it to withstand the abrasive effects of materials like sand, gravel, and dust particles. Furthermore, the sleek surface of steel sheets aids in diminishing friction and preventing the accumulation of debris, thereby bolstering their performance in abrasive surroundings. Steel sheets can endure the impact of abrasive materials without deforming or sustaining damage, rendering them highly suitable for demanding sectors such as construction, mining, and manufacturing industries. Nevertheless, it is worth emphasizing that certain steel variants, such as stainless steel, exhibit enhanced resistance against corrosion and rust, which are additional factors to consider in abrasive environments. Routine upkeep and the application of protective coatings can further optimize the performance and lifespan of steel sheets in abrasive settings.

- Q: Do the steel sheets have any specific certifications?

- The quality and compliance of the steel sheets are ensured through specific certifications. These certifications are typically granted by reputable organizations like the International Organization for Standardization (ISO) or specific regulatory bodies based on the country or region. The common certifications for steel sheets include ISO 9001 for quality management systems, ISO 14001 for environmental management systems, and ISO 45001 for occupational health and safety management systems. Furthermore, there might be industry-specific certifications, such as the American Society for Testing and Materials (ASTM) standards or the European Committee for Standardization (EN) certifications. These certifications guarantee that the steel sheets meet specific criteria for various attributes, including material composition, mechanical properties, and manufacturing processes.

- Q: Can steel sheets be used for mezzanine floors?

- Yes, steel sheets can be used for mezzanine floors. Steel is a commonly used material for constructing mezzanine floors due to its strength, durability, and ability to support heavy loads. Steel sheets can be used as the primary flooring material or as a subflooring layer, providing a stable and secure platform for various applications.

- Q: Are steel sheets suitable for electrical grounding applications?

- Indeed, electrical grounding applications can find steel sheets to be fitting. As a proficient conductor of electricity, steel can proficiently transmit electrical charges to the ground. Due to their endurance, robustness, and cost-efficiency, steel sheets are frequently employed in grounding applications. Their installation is simple, and they offer a trustworthy link to the earth, guaranteeing a secure pathway for electrical currents in the event of a fault or surge. Nevertheless, it is imperative to ensure the proper installation and upkeep of steel sheets, as any corrosion or harm can impede their conductivity and hinder their efficacy in grounding electrical systems.

- Q: What industries commonly use steel sheets?

- Several industries commonly use steel sheets, including construction, automotive, aerospace, manufacturing, and shipbuilding.

- Q: What is the difference between hot dipped galvanized and electro galvanized steel sheets?

- Hot dipped galvanized and electro galvanized steel sheets are both types of galvanized steel, but they differ in the method of application and the resulting characteristics of the coating. Hot dipped galvanized steel sheets are made by immersing the steel into a molten zinc bath. This process creates a thick, durable coating that provides excellent corrosion protection. The steel is completely coated in zinc, both on the surface and on the edges, ensuring complete coverage and protection against rust and other forms of degradation. The coating thickness can vary depending on the application and the required level of protection. On the other hand, electro galvanized steel sheets are produced by electroplating steel with a thin layer of zinc. The steel is first cleaned and treated with an acid solution to remove impurities and improve adhesion. Then, it is immersed in a zinc electrolyte solution, and an electric current is passed through the bath, causing the zinc ions to bond with the steel surface. This process results in a much thinner coating compared to hot dipped galvanized steel. Due to the thinner coating, electro galvanized steel sheets provide less corrosion protection than hot dipped galvanized steel sheets. They are more suitable for indoor applications or environments with less exposure to harsh conditions. However, electro galvanized steel sheets offer other advantages such as a smoother and more uniform appearance, making them popular for applications where aesthetics are important, such as automotive parts or appliances. In summary, the main difference between hot dipped galvanized and electro galvanized steel sheets lies in the method of application and the resulting coating thickness. Hot dipped galvanized steel sheets have a thicker, more durable coating, providing superior corrosion protection, while electro galvanized steel sheets have a thinner coating, making them more suitable for indoor applications and offering a smoother appearance.

Send your message to us

Hot Rolled Carbon Steel Plate,Carbon Steel Sheet CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords