Hot-Dip Galvanized Steel Coil Used for Industry with So Much Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

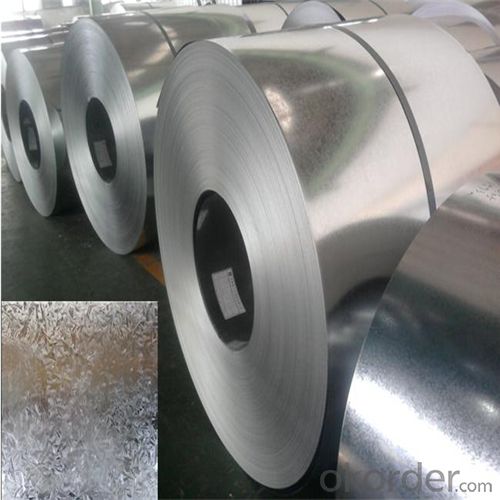

Hot-Dip Galvanized Steel Coil Used for Industry

1.Structure of Hot-Dip Galvanized Steel Coil Description

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful countless outdoor and industrial applications.

2.Main Features of the Hot-Dip Galvanized Steel Coil

•High Purity

•Easy control and operation

•High strength

•Fast melting

•Competitive price

•Best Service

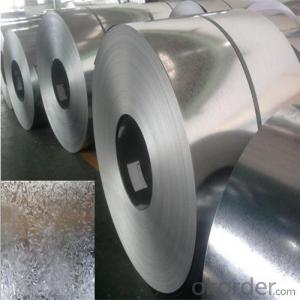

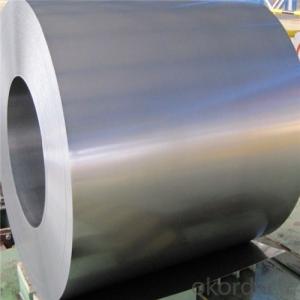

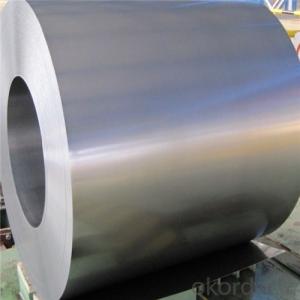

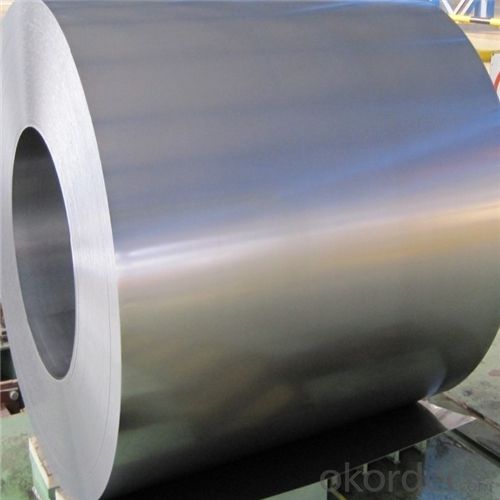

3. Hot-Dip Galvanized Steel Coil Images

4. Hot-Dip Galvanized Steel Coil Specification

Hot-Dip Galvanized Steel Coil | |

Thicknenss | 0.10mm-5.00mm |

Width | 2000mm max |

Coating mass | 30-600g/㎡ |

Spangle | Regular/Minimized/Zero Spangle |

Coil inner diameter | 508-610mm |

Surface treatment | Chromated/non chromated, Oiled/non oiled, Anti finger print |

5.FAQ of Hot-Dip Galvanized Steel Coil

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How are steel coils used in the manufacturing of electrical transformers?

- Steel coils are used in the manufacturing of electrical transformers as they provide structural support and act as a core for the transformer. The steel coils are wound with copper wire to create the primary and secondary windings, which help in transferring electrical energy efficiently.

- Q: How are steel coils used in the production of packaging machinery?

- Steel coils are used in the production of packaging machinery to create various components such as frames, supports, and structural parts. These coils are shaped, cut, and formed into specific designs to provide strength, durability, and stability to the machinery. Additionally, steel coils can be used to fabricate conveyor belts, rollers, and other moving parts, ensuring smooth operation and efficient packaging processes.

- Q: How are steel coils welded together?

- Different methods can be employed to weld steel coils together, depending on the specific requirements and the type of steel being used. Electric resistance welding (ERW) is a common method where an electric current is utilized to generate heat in the coils, melting their edges. Pressure is then applied to join them together. ERW is a cost-effective and speedy technique for welding steel coils. Thinner steel coils are often welded using high-frequency induction welding (HFIW). This involves the use of an induction coil to produce an alternating magnetic field, inducing an electric current in the coils. The resistance of the coils to this current generates heat, causing the edges to melt and form a weld. For thicker and heavier steel coils, submerged arc welding (SAW) is commonly employed. This technique utilizes a granular flux and a continuous electrode that is fed into the weld area. The flux melts, creating a protective shield for the weld pool, while the electrode melts to form the weld. SAW is a robust and efficient method for welding steel coils. In addition to these methods, laser welding and gas metal arc welding (GMAW) can also be utilized for welding steel coils. Laser welding offers high precision and speed, while GMAW, also known as MIG welding, utilizes an electric arc between a consumable wire electrode and the steel coils to create a weld. Irrespective of the welding method employed, successful welding of steel coils hinges on proper edge preparation, maintenance of appropriate heat and pressure levels, and the use of correct welding techniques.

- Q: Please people suggest me how can I select external finishing for Steel Building as there is a wide range of choice available.

- Hi okorder /

- Q: What are the main factors that affect the flatness of steel coils?

- The main factors that affect the flatness of steel coils are the quality and thickness of the steel material, the tension and speed of the rolling process, the temperature and cooling rate during the cooling process, and any potential defects or imperfections in the machinery used for rolling and cooling the steel coils.

- Q: What are the dimensions of steel coils used in the agricultural machinery industry?

- The dimensions of steel coils used in the agricultural machinery industry can vary depending on the specific application and requirements. However, common dimensions for steel coils used in this industry typically range from 0.5 to 2.0 millimeters in thickness and 600 to 1500 millimeters in width. These dimensions are suitable for various agricultural machinery components such as panels, frames, brackets, and reinforcements. It is important to note that these dimensions can be customized based on the specific needs of the machinery or the manufacturer's specifications.

- Q: How do steel coil manufacturers handle customer complaints?

- Steel coil manufacturers handle customer complaints by following a structured process to address and resolve the issues raised by customers. Firstly, when a customer complaint is received, it is important for the manufacturer to carefully listen and understand the nature of the complaint. This involves actively engaging with the customer to gather all relevant details and information regarding the issue. It is crucial to maintain clear communication and ensure the customer feels heard and valued. Once the complaint has been fully understood, the manufacturer should promptly investigate the situation. This may involve reviewing production records, analyzing quality control measures, or conducting internal inspections. The aim is to identify the root cause of the problem and determine if it was a result of a manufacturing defect, shipping mishap, or any other factor. After the investigation, the manufacturer should provide a timely response to the customer. This response should include an explanation of the findings, an acknowledgment of the customer's concerns, and a proposed solution or resolution. The proposed solution might involve replacing the defective coils, offering compensation, or providing expert advice on how to mitigate the issue. To prevent similar complaints in the future, the manufacturer should also take steps to rectify any internal shortcomings. This could involve revisiting quality control procedures, improving communication among departments, or implementing additional training for employees. Furthermore, steel coil manufacturers should strive to maintain an open and transparent line of communication with customers throughout the complaint handling process. This includes providing regular updates on the progress of the investigation and promptly addressing any further concerns or questions raised by the customer. Overall, the key to handling customer complaints in the steel coil manufacturing industry is to prioritize customer satisfaction and ensure a fair and efficient resolution. By following a structured approach, actively listening to customers, and taking appropriate corrective actions, manufacturers can effectively address customer complaints and maintain positive relationships with their clients.

- Q: Is it possible that stainless steel watches get rust. Any experience? Thanks.

- Stainless can oxidize over time but it doesn't look much like regular rust. Depending on the exact composition of the stainless alloy in question and what other materials are in contact with it, that's more or less of an issue. In constant contact with skin oils and gentle polishing from contact with skin and clothing, watches rarely rust regardless of what they're made of, I think you have nothing to worry about. Note: for future reference, bleach is absolute hell on stainless. It's bad enough on steel, worse on stainless. Especially because you have this idea that stainless is more or less impervious, when in reality it just isn't.

- Q: What are the common thickness tolerances for steel coils?

- The common thickness tolerances for steel coils usually range from +/- 0.001 to +/- 0.005 inches, depending on the specific industry standards and customer requirements.

- Q: What is the role of steel coils in the automotive industry?

- The automotive industry heavily relies on steel coils as the primary raw material for manufacturing various vehicle components. These coils, made from high-quality steel, are shaped into a continuous strip that can be easily processed to create desired automobile parts. One crucial application of steel coils in the automotive industry is their role in producing body panels and frames. Through stamping and forming techniques, these coils are transformed into panels like doors, hoods, fenders, and roofs. Steel coils provide the necessary strength, durability, and rigidity to protect passengers and other vehicle components from external forces. Furthermore, steel coils are also used in manufacturing various structural components of automobiles. Chassis, suspension systems, engine cradles, and brackets are typically produced using steel coils due to their excellent mechanical properties. Their high tensile strength enhances the overall structural integrity of the vehicle, ensuring safety. Additionally, steel coils are integral in producing automotive springs, which are essential for the suspension system. Coil springs, leaf springs, and torsion bars are commonly used to absorb shocks, provide stability, and maintain proper ride height. The utilization of steel coils in these applications guarantees optimal performance, durability, and longevity of the suspension system. In conclusion, the versatility, strength, and durability of steel coils make them vital in the automotive industry. They are utilized in manufacturing body panels, frames, structural components, and suspension systems, contributing to the overall safety, reliability, and performance of vehicles.

Send your message to us

Hot-Dip Galvanized Steel Coil Used for Industry with So Much Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords