Hot-Dip Galvanized Steel Coil Used for Industry with Our Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-Dip Galvanized Steel Coil Used for Industry

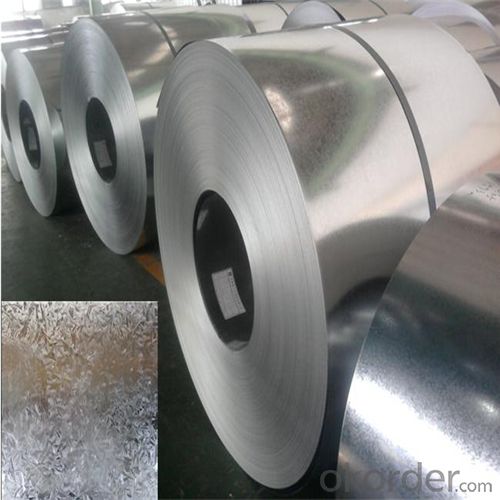

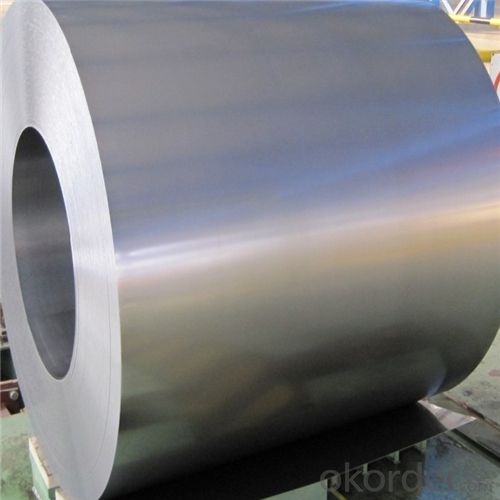

1.Structure of Hot-Dip Galvanized Steel Coil Description

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc.

2.Main Features of the Hot-Dip Galvanized Steel Coil

•High Purity

•Easy control and operation

•High strength

•Fast melting

•Competitive price

•Best Service

3. Hot-Dip Galvanized Steel Coil Images

4. Hot-Dip Galvanized Steel Coil Specification

Hot-Dip Galvanized Steel Coil | |

Thicknenss | 0.10mm-5.00mm |

Width | 2000mm max |

Coating mass | 30-600g/㎡ |

Spangle | Regular/Minimized/Zero Spangle |

Coil inner diameter | 508-610mm |

Surface treatment | Chromated/non chromated, Oiled/non oiled, Anti finger print |

5.FAQ of Hot-Dip Galvanized Steel Coil

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: On a free standing carport with an 8 inch, 22 foot long aluminum i-beam, would a steel 8-inch i-beam be just as strong? I am looking into it since they are cheaper.

- steel is definitely cheaper than aluminum. for the same size, steel is stronger. and much heavier. it may/will require stronger support posts. you'll want to be careful not to set up a galvanic reaction where you have steel and aluminum meet. stainless steel is much more expensive. you just want to make sure your steel beams have a good rustproof coating. either zinc plate or paint.

- Q: and what type of metal is steel?

- Steel is an alloy consisting mostly of iron, with a carbon content between 0.2% and 2.14% by weight (C:110–10Fe), depending on grade. Carbon is the most cost-effective alloying material for iron, but various other alloying elements are used such as manganese, chromium, vanadium, and tungsten. Carbon and other elements act as a hardening agent, preventing dislocations in the iron atom crystal lattice from sliding past one another. Varying the amount of alloying elements and form of their presence in the steel (solute elements, precipitated phase) controls qualities such as the hardness, ductility, and tensile strength of the resulting steel. Steel with increased carbon content can be made harder and stronger than iron, but is also more brittle.

- Q: I moved into a house which has a steel front door.When I touch the door it feels very cold to the touch in the winter.There is a storm door also and the weather stripping looks good.Cold air from the door is entering the lower level.The house is about 20 yrs old.

- Not all doors are created equal so maybe it has insulation but doubtful. 20yrs ago they didn't put insulation into doors and a solid steel door is not light and would rip the hinges off. They do not put solid steel doors into homes Your door is steel sheet metal thin and the door is hollow core air in between them that's why its cold A solid wood door with proper insulation around it and weather stripping under it is more efficient in preventing heat loss The only purpose of a steel door is security, harder to kick in a steal door, which is the reason why it was installed. The old owner probably got the house robbed and they kicked in the original flimsy door. So it was recommended that he use a steel door. Steel does not insulate against hot or cold it absorbs it. Hence why its cold, no amount of weather stripping will prevent heat loss the door itself absorbs heat and cold The cure is another door solid core wood door is strong and does not have the same properties as steel doors Hope that helps Lr

- Q: Are steel coils affected by temperature changes?

- Yes, steel coils can be affected by temperature changes. Steel is a metal that expands when heated and contracts when cooled. This expansion and contraction can lead to changes in the dimensions and shape of steel coils. Additionally, extreme temperature variations can cause thermal stress, which may result in warping, cracking, or weakening of the steel coils. Therefore, temperature changes can have an impact on the performance and integrity of steel coils.

- Q: Can steel coils be coated with zinc-nickel alloy?

- Yes, steel coils can be coated with a zinc-nickel alloy. Zinc-nickel alloy coating provides excellent corrosion resistance and is commonly used in various industries including automotive, construction, and manufacturing.

- Q: What are the common coil edge finishes?

- Some common coil edge finishes include slit edge, mill edge, and deburred edge.

- Q: so why shouldn't one use a steel cased 223 in an ar15?

- You can. A steel case is cheaper to make than a brass case, resulting in cheaper ammo, in wich they normaly use cheap, corrosive loadings. So steel cased stuff will normally be very dirty to shoot. Clean your gun after shooting and you will be fine. The story of them wearing the extractor is crap, however: the extractor is made of a steel way harder than the cheapo-steel the case is made of. It wonn? scrach it. Even if it would, considering the amount of money you save with the cheap ammo like bear and wolf, changing the extractor once in a while would still be saving you a ton of money.

- Q: I'm getting my nose pierced, meaning that i have to keep the piercing in for a prolonged time. i've always had reactions when wearing sterling silver or fake earrings (i dont know what types of metal they were) after wearing it overnight. Will I get a reaction on my nose piercing if the stud is surgical steel?

- Surgical Piercing

- Q: What are the different coil winding methods used for steel coils?

- The different coil winding methods used for steel coils include cross-winding, helical winding, and layer winding. Cross-winding involves winding the steel coil in a crisscross pattern to ensure even distribution of the material. Helical winding involves winding the steel coil in a spiral pattern, which provides strength and stability to the coil. Layer winding involves winding the steel coil in layers, with each layer placed on top of the previous one, ensuring efficient use of space and easy unwinding of the coil.

- Q: Hi can someone help me pleaseis there any available data for mechanical behaviour of recycled steel, i need to compare them with new steel.

- It is not clear from the question whether the recycled steel is used in its existing state or used as raw material for further fabrication. For the existing steel, you need to track down the original documents such as the ladle analysis and mill certificates certifying the material standards for which the steel was fabricated. Another alternative is take samples and conduct chemical and mechanical tests on the steel. Also the date of when the structure was built from which the steel is recycled may help indicate whether it is (American Society for Testing and Materials) Standard ASTM A7 or ASTM A36 or another type of steel. In most cases, the steel is used as raw material to make new steel. The mill will adjust the additives to produce steel with the required chemical and physical properties to meet the ASTM standards specified.

Send your message to us

Hot-Dip Galvanized Steel Coil Used for Industry with Our Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords