Hot-Dip Galvanized Steel Coil Used for Industry with Too Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-Dip Galvanized Steel Coil Used for Industry

1.Structure of Hot-Dip Galvanized Steel Coil Description

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful countless outdoor and industrial applications.

2.Main Features of the Hot-Dip Galvanized Steel Coil

•High Purity

•Easy control and operation

•High strength

•Fast melting

•Competitive price

•Best Service

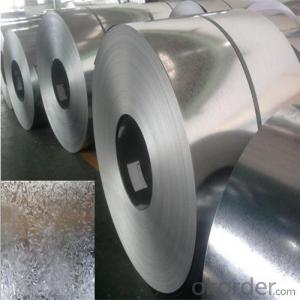

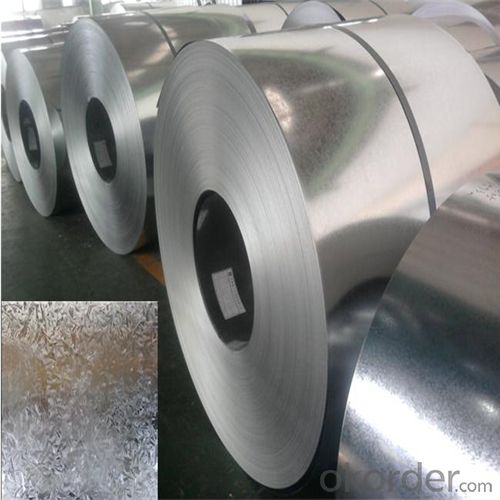

3. Hot-Dip Galvanized Steel Coil Images

4. Hot-Dip Galvanized Steel Coil Specification

Hot-Dip Galvanized Steel Coil | |

Thicknenss | 0.10mm-5.00mm |

Width | 2000mm max |

Coating mass | 30-600g/㎡ |

Spangle | Regular/Minimized/Zero Spangle |

Coil inner diameter | 508-610mm |

Surface treatment | Chromated/non chromated, Oiled/non oiled, Anti finger print |

5.FAQ of Hot-Dip Galvanized Steel Coil

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: How are steel coils used in the manufacturing of automotive parts?

- Steel coils are used in the manufacturing of automotive parts as they are shaped and formed into various components such as body panels, chassis frames, and suspension parts. The coils are processed through a series of steps including cutting, bending, and stamping, to create the desired shape and size for each specific part. These steel components provide strength, durability, and structural integrity to the automobiles, ensuring their safety and performance on the road.

- Q: Hi All,I was wanting to know,on the quality bikes such as Trek,Giant etc is the aluminum frames as strong as the steel frame bikes? I have heard conflicting reports on this,so thought I would ask here for more input.Thanks!

- Dustin You are close, but not quite right. Steel is a great frame material, It can be heavier than its aluminum counter part, But, steel often provides a much nicer ride. Aluminum tends to be a very stiff and rigid ride that many do not like. I have had frames made of all materials. I can say that I have never met a frame material that I did not like. Check the weight of the frames you are looking at. If there is more than two pound (or so) difference then the aluminum frame would be my choice. Soccerref

- Q: How are steel coils handled during transportation to prevent damage?

- Steel coils are typically handled during transportation by using specialized equipment such as cranes or forklifts with padded forks. They are secured with steel bands or other restraints to prevent movement and damage. Additionally, they are usually loaded onto flatbed trucks or shipping containers with proper cushioning and support to minimize the risk of impact or deformation during transit.

- Q: What are the different types of steel coil cutting machines?

- In the market, there is a wide range of steel coil cutting machines available, each tailored to meet specific needs and requirements. Some commonly used types include: 1. Slitting Machines: These machines are utilized to cut steel coils into narrower strips. Equipped with multiple circular blades, they are capable of making precise cuts along the length of the coil, enabling the production of narrower coils or strips. 2. Cut-to-Length Machines: Designed to cut steel coils into specific lengths, these machines possess the ability to accurately measure and cut the coil to the desired length, ensuring uniformity and precision. 3. Rotary Shears: Rotary shears are robust cutting machines that can handle thicker and larger steel coils. Utilizing a rotating blade, they are suitable for cutting thicker gauge materials. 4. Multi-Blanking Machines: Intended for cutting steel coils into multiple smaller blanks simultaneously, these machines have the capability to cut the coil into various shapes and sizes. This makes them ideal for producing multiple parts from a single coil. 5. Slit and Cut-to-Length Combination Machines: These machines integrate the functionalities of both slitting and cut-to-length machines, enabling the cutting of narrow strips and lengths in a single process. They offer versatility and efficiency, saving time and increasing productivity. Each type of steel coil cutting machine possesses distinct advantages and is suitable for specific applications. The choice of machine depends on factors such as coil thickness, desired strip width, required length accuracy, and production volume.

- Q: i know theres steel in it but what else?

- Chromium, nickel and molybdenum. Along with less carbon.

- Q: How are steel coils used in the manufacturing of seat structures?

- Steel coils are used in the manufacturing of seat structures as they provide strength, durability, and stability to the seats. These coils are typically used in the construction of seat springs, which offer support and comfort to the occupants. The steel coils are carefully designed and placed within the seat structure to ensure proper weight distribution and to withstand the pressure exerted on the seats during usage.

- Q: How long does the coating on steel coils last?

- The longevity of the coating on steel coils depends on various factors such as the type of coating used, the environmental conditions it is exposed to, and the maintenance practices. However, on average, a well-applied coating can last anywhere from 10 to 20 years before requiring reapplication or maintenance.

- Q: How are steel coils used in the manufacturing of tools?

- Steel coils are often used in the manufacturing of tools as they provide a sturdy and durable material to create various components of the tools. The coils are shaped and cut into specific sizes and shapes to form the tool's body, handles, or blades. This allows for the production of high-quality tools that can withstand heavy use and provide the necessary strength and reliability required for different applications.

- Q: What are the different grades of steel used for manufacturing coils?

- Manufacturing coils requires the use of various grades of steel, each selected for their specific properties and suitability for different purposes. Some commonly used grades include low carbon steel, high carbon steel, stainless steel, galvanized steel, and alloy steel. Low carbon steel, also known as mild steel, is a cost-effective option with good formability. It is ideal for applications that require low strength and high ductility, such as automotive components and construction materials. High carbon steel is characterized by its exceptional strength and hardness. It is commonly employed in the production of coils that demand high tensile strength, like springs and wires. Stainless steel, an alloy with a high chromium content, offers corrosion and oxidation resistance. It is often utilized in the manufacturing of coils for the food industry, medical equipment, and automotive applications. Galvanized steel, on the other hand, is steel coated with a layer of zinc to safeguard it against corrosion. It is frequently used in the production of coils that will be exposed to harsh environmental conditions or require excellent durability, such as roofing materials and electrical appliances. Alloy steel, formed by adding elements like manganese, nickel, chromium, or molybdenum to carbon steel, exhibits improved strength, hardness, and resistance to wear and corrosion. It finds wide application in industries that necessitate high strength and toughness, such as aerospace and automotive. Choosing the appropriate grade of steel is crucial to ensure optimal performance and longevity of the coils, as it is essential to match the specific requirements of the application.

- Q: Does Steel Cut Oatmeal have the same health benefits as Old Fashioned Oatmeal? What is the difference in processing?

- Steel Cut Oats Steel-cut oats are whole oat kernels cut into small chunks rather than being smashed flat as in oatmeal. This gives the oats more of a chew texture and also slows both cooking time and digestion time. That means that they have a lower glycemic index and are thus preferable for increasing satiety, lowering the insulin response to the meal, and keeping blood sugar levels from peaking. This also results in delaying hunger so a person is less likely to snack or get overly hungry before the next meal. Here is how I like to cook oats for breakfast. Ingredients 1/2 cup Dry steel cut oats 1 cup Water (You may want a little more than a cup, experiment to your liking) 2 T Raisins (optional or replace with chopped dried apricots etc.) 2 T Ground flax meal (optional, but high in healthy n-3 fatty acids and fiber) Salt to your taste (try Lite salt to lower sodium intake) 2T Sunflower seeds or almonds 1 cup Fresh berries or a banana Directions Heat water to a boil. While water is heating, add the salt, raisins, and flax meal. When the water boils, add the steel cut oats. Stir once. Turn heat down to simmer and cook covered for 7-8 minutes. Provides two small servings. Double for large servings or small servings for 4 people. Serve and eat while hot. Add soy milk or low fat milk. Slice fresh fruit on top to add extra flavor. My wife likes banana slices. I like fresh berries, peaches, or sugar free applesauce. For extra crunch sprinkle almonds or sunflower seeds on top.

Send your message to us

Hot-Dip Galvanized Steel Coil Used for Industry with Too Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords