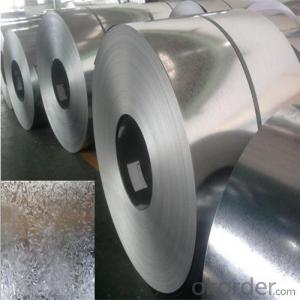

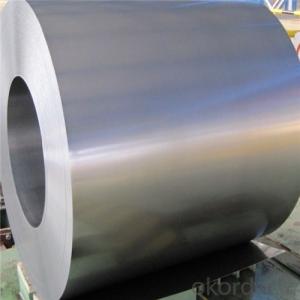

HOT-DIP GALVANIZED STEEL COIL OF HIGH QUALITY

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

· Standard: AISI, ASTM, BS, DIN, GB, JIS

· Grade: SPCC, SPCD, Q195, DX51D

· Thickness: 0.15-5.0mm

· Model Number: coil

· Type: Steel Coil

· Technique: Cold Rolled

· Surface Treatment: Galvanized

· Application: Container Plate

· Special Use: High-strength Steel Plate

· Width: 600-1250mm

· Length: depends

· commodity: hot dipped galvanized steel coil

· technique: cold rolled

· thickness: 0.15-5.0mm

· width: 600-1500mm

· surface treatment: galvanized

· zinc coating: 50-275g/m2

· coil weight: 3-7 tons

· coil ID: 508/610mm

· spangle: zero spangle, regular spangle, small spangle, big spangle

· payment term: by L/C or T/T

- Q: How are steel coils used in the manufacturing of engine mounts?

- Steel coils are commonly used in the manufacturing of engine mounts to provide durability, strength, and flexibility. These coils are typically designed to absorb and dampen vibrations, shocks, and movements generated by the engine during its operation. By integrating steel coils into the engine mount design, manufacturers can ensure better stability, improved performance, and reduced noise levels in vehicles.

- Q: Is steel case ammo going to mess the gun up or is it just going to wear the parts out faster and if so how much faster? (I am not planning on reloading the rounds)

- The ak was designed with the steel cased ammo in mind. The only real wear is going to be the chamber area, and even at that, it is going to take many thousands of rounds to wear it out. be more concerned with the corroive ammo, and clean the firearm well with warm soapy water or military bore cleaner after each shooting session.

- Q: How are steel coils protected against fire and heat?

- Steel coils are typically protected against fire and heat through various methods such as fire-resistant coatings, fire blankets, water-based sprays, or the use of fire-resistant barriers or walls in the storage area. Additionally, fire detection and suppression systems, such as sprinkler systems, are often installed to quickly extinguish any potential fire.

- Q: How are steel coils used in the manufacturing of steel drums?

- Steel coils are used in the manufacturing of steel drums by being shaped and welded into the cylindrical body of the drum. The coils are unrolled and cut to the desired length, then formed into a circular shape and welded together to create a seamless drum.

- Q: How are steel coils used in the production of doors and windows?

- The strength and versatility of steel coils make them crucial in the manufacturing process of doors and windows. Typically made from high-quality steel, these coils have various applications. To begin with, steel coils are utilized in the creation of door and window frames. When unrolled, they are cut into specific lengths to match the desired dimensions of the frame. The steel is then bent and shaped into the required design, ensuring durability and strength. Furthermore, the coils are employed in producing the panels or glass holders for doors and windows. The steel is cut and formed into the desired shape, and then either welded or attached to the frame. This guarantees a sturdy structure capable of withstanding the weight and pressure of the glass or panels. In addition, steel coils are also used for manufacturing hinges and other hardware components. By cutting and shaping the coils, the necessary parts are created, ensuring sufficient strength to support the movement and functionality of the doors and windows. Moreover, steel coils serve decorative purposes as well. They can undergo embossing or be coated with different finishes, enhancing the appearance of doors and windows. This vast range of design options enables manufacturers to create products that cater to various architectural styles and individual preferences. In essence, steel coils play a pivotal role in the production of doors and windows. From creating frames, panels, hinges, and hardware components to offering customization and aesthetic appeal, their importance cannot be overstated.

- Q: What is the maximum stacking height for steel coils?

- The maximum stacking height for steel coils depends on various factors such as the weight and size of the coils, the strength of the supporting structure, and the safety regulations and guidelines in place. It is recommended to consult the manufacturer's specifications and industry standards to determine the appropriate maximum stacking height for steel coils in a specific situation.

- Q: How are steel coils used in the manufacturing of suspension arms?

- Steel coils are used in the manufacturing of suspension arms as they provide the necessary strength and flexibility required to absorb shocks and vibrations, ensuring a smooth and stable ride. The coils are typically placed around the suspension arm and compressed under the weight of the vehicle, allowing them to act as springs, supporting the weight of the vehicle and maintaining proper suspension alignment.

- Q: What are the dimensions of steel coils used in the oil and gas industry?

- The dimensions of steel coils in the oil and gas industry can differ based on the specific application and needs. Nevertheless, there are commonly used dimensions. Steel coils in the oil and gas industry typically possess a width that ranges from 600mm to 2000mm. The coil's outer diameter can vary from 800mm to 2200mm, while the inner diameter can range from 508mm to 610mm. The coil's weight can also vary, ranging from a few tons to several tens of tons. These dimensions are tailored to fulfill the requirements of diverse processes in the oil and gas industry, including pipe manufacturing, storage tank fabrication, and offshore platform construction. It is important to emphasize that these dimensions are not fixed and can be customized to meet the specific demands of each project.

- Q: How are steel coils used in the production of storage systems?

- Steel coils are used in the production of storage systems by being formed into sheets or strips, which are then shaped and welded to create the framework and shelves of the storage units. The high strength and durability of steel make it an ideal material for supporting heavy loads and ensuring the longevity of storage systems.

- Q: I want to purchase a set of knives made of carbon steel and want to be able to store them on a magnetic knife strip for handy access, I just wasn't sure if this alloy would stick to a magnet????Thanks

- Carbon steel knives will stick to a magnet. Stainless steel may not.

Send your message to us

HOT-DIP GALVANIZED STEEL COIL OF HIGH QUALITY

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords