Horizontal Submersible Cement Screw Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Working Features

Wide application, delivery all kinds of fluid media, even non-fluid ones

Bilateral rotation and delivery

Stable capacity and pressure, no pulse

Capacity is proportional to speed, so the pump can be used as dosing pump

Low operated noise, no-leakage and no temperature rise

Long life, low cost of operation maintenance

Delivery Media

Different viscous liquids, especially for the liquids with high viscosity which are difficult to be pumped. (up to 106 mm2/s)

Different dense liquids and dewatered dry medium

Liquids with solid particles (up to 70%), fibers (up to 350mm) and suspending media

Sensitive liquids that cannot be churned, sheared and compressed

Corrosive liquids (pH=0-14)

Fluid at high or low temperature (-10 – 150 C)

Application Area

Environmental Engineering

Separate oil from water and desulfurize from waste air

Metering and dosing flocculation and other chemical compound

Delivery of dewatered sludge

Delivery of all kinds of sewage

Paper Making Industry

Dregs slurry and waste water treatment

Metering for chemical slurry

Spreading and coloring process

Preparing for material

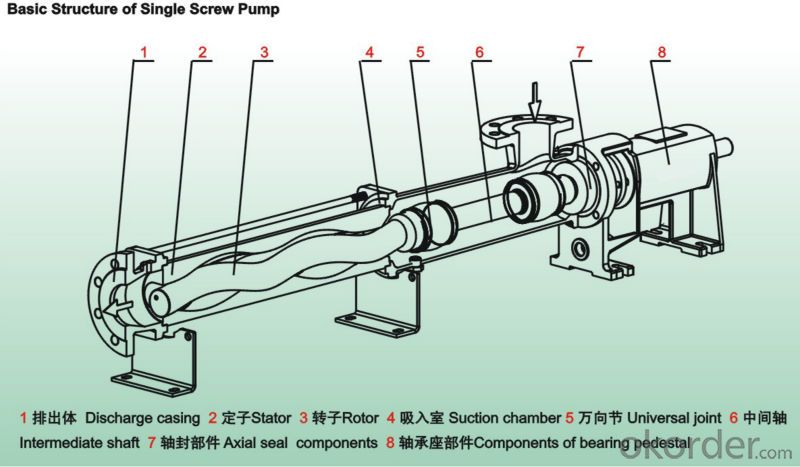

The material of components is dependent on medium features:

Pump body (suction chamber, discharge casing and others) which connects with media:

cast iron, carbon steel, different stainless steel or flow surface plated with anti-corrosive materials are available;

Rotor: strong anti-abrasive alloy steel, different stainless steels and anti-corrosive alloy steel are available;

Stator: different rubber and other elastic materials are available;

Axial seal components: packing or mechanical seal according to your requirements.

Structure

- Q: Variable flow pumps are variable pumps

- Yes. The variable pump is designed to change the flow rate

- Q: What are the ways of hydraulic pumps?

- There are several ways:Direct flow mode, such as external gear pump;Port plate, such as vane pump, axial piston pump, etc.;

- Q: What should I pay attention to when buying a pump?

- There are hundreds of water pump manufacturers in China, some of the family owned private enterprises are assembled in some areas, and the quality of the products is very good and bad, which makes it difficult to choose and buy. The main points are as follows:First, according to the required flow, lift, shaft power, efficiency, the necessary cavitation margin (or suction) and the use of conditions, the initial determination of the pump type, name, select the rated value and the required parameters of the same pump.

- Q: There are 6 pumps, two indoor fire hydrant pumps, two spray pumps, two outdoor pumps, three units, one master and one spare control cabinet. From the control room to the control cabinet, is there only 3 lines or 9 lines?... How do I get it? Where does the hydrant line come from?

- Indoor fire hydrant pump in addition to remote direct Kai, there are modules to start function, that is, on the cabinet to add control module, bus linkage pump, but also fire hydrant button, direct pumping function, a total of three functions.Outdoor fire hydrant pump in addition to remote direct Kai, but also an electric contact pressure meter detection system, water pressure from the pump and high pressure pump stop function.

- Q: Is the diaphragm pump and the drain pump one?

- Therefore, the need to play a liquid discharge pump, if the medium is corrosive liquid, high viscosity, volatile, flammable, highly toxic liquid, you can choose diaphragm pump. Conversely, the general liquid, there is no special requirements, you can use the general centrifugal pump to reduce costs.

- Q: There are second cutting, third cutting, why three times?

- There are 2 situations, first, for example, a XXXX-160 type pump head 32, flow 100, motor 15kW, according to the model we need to cut a become head 28, flow rate of 88, this time, in addition to cutting the impeller, the pump or the original pump motor, became 11kW this is, re designed a new model, namely XXXX-160A, but most structural components did not change. In the same way, we want to design a XXXX-160B that makes the head 24 and the flow rate 80, then we just need to cut the impeller again and match the smaller (7.5kW) motor (the motor bracket needs to be redesigned). In general, multiple cutting impellers are designed to expand and enrich the model. Second, the actual use, if you think the flow head is too large, but also can be cut to make it smaller to adapt to practical applications. But the 2 and 3 cuts you ask are the first.

- Q: Why can the centrifugal pump hold down the pressure?

- The centrifugal pump can hold pressure because of the suction pipe in the pump at the entrance of a non-return valve (valve).

- Q: What is the pump delivery? What's the difference between years and years?

- First of all, as a student majoring in insurance, I strongly condemn the first floor of ignoring practice and trampling on real knowledge!!The insurance industry criticized a lot, but it is required for many people, we should face and try to maintain the healthy development of the industry, the first floor of the insurance you have not done, have no contact with the insurance, insurance, not to dictate the nonsense, more should not be here misleading!

- Q: Why can't the centrifugal pump pump the vacuum?

- Running process: depending on the centrifugal pressure of the liquid in the impeller, the liquid is sucked into the liquid, and the liquid in the pump shell has the conversion of the energy form, so that the fluid can obtain the mechanical energy mainly with the static pressure.The characteristics of the system: the suction diameter than out of large diameter, the general valve installed.

- Q: Filter backwash pump for what use, what is the principle of work ah?

- Regeneration of the filter medium is required to regain the filtration capacity of the medium. The regeneration process is mainly accomplished by the backwashing pump (the backwash pump is not a special pump, referring to the pump for the completion of the process). The working principle is through the cleaning liquid from the downstream of the filter into the backwash pump (alkali, acid and water), reverse flushing filter medium, cleaning liquid discharged from the upstream, this process can be attached to the dielectric surface and internal impurities washed away.

Send your message to us

Horizontal Submersible Cement Screw Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches