Horizontal Multistage Designed Stainless Steel Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 2000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of Horizontal Multistage Designed Stainless Steel Pump.

1>Horizontal multistage stamping welding impeller and diffuser,three different type of choice.

2>Single phase motor up to 2.2kw,Class F and IP55 motor is standard.

3>Standard supply for liquid temperature up to 70 degree centigrade,high temperature pump are available on request.

2. Application for the Horizontal Multistage Designed Stainless Steel Pump.

1>cooling water system

2>agriculture

3>domestic water supply

4>general industrial services

5>washing

6>enviroment protection

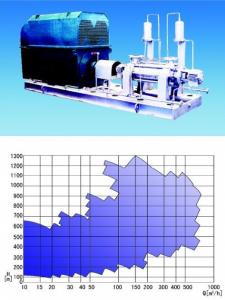

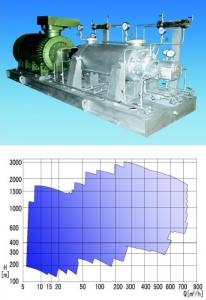

3. Performance range for Horizontal Multistage Designed Stainless Steel Pump.

capacity: Q up to 32m3/h

head H up to 110 degree centigrade

speed: n 2900rpm or 3500rpm

power: P up to 55kw *2

4. Standard material of Horizontal Multistage Designed Stainless Steel Pump.

All the parts contact with liquid made of 304 stainless steel on request.The pump head and suction & discharge can be made of cast iron on request too.

5. RFQ

1> What's the difference for CHL and CHLF(T) type?

CHL pumps have an inlet and outlet chamber which is made by stainless steel. CHLF(T) is just the section type.

2> Do you have any variable motor for these pumps?

Yes, we have. For the variable motor, the frequence can be changed as the customers' request. If the range is between 30~50Hz, the fan can be just connected with the shaft. And if the frequency is below 30Hz, then the fan has to have another separated power. The variable speed motor would be used for solar energy or some other similar situation with the unstable power.

3> How about the Delivery time?

Actually, this would be depending on the quantity. If it is just small order, 1 week would be fine. For bigger quantity, the delivery would be also less then 20 days. But for the varible speed ones, it will be taking some more time, normally it will be more than a month.

- Q: Troubleshooting of diaphragm pump

- In the application of the pump, these conditions are likely to encounter. Each situation can be divided into several possible reasons. This guide lists the causes of failures and gives appropriate corrective maintenance measures. The meaning of all the specific terms in the guide is listed later.Air valves - copper or stainless steel valves are bolted to the center of the pump by four bolts.The piston aluminum cylinder is enclosed in the air valve to control the gas flow.Cavitation - because the pump inlet for the amount of fluid to reduce or lack, the pump discharge is less than the amount of quantitative. In fact, the fluid chamber is full of fluid before it is discharged.Static pressure drop - the inlet pressure from the pump centerline to the free point - the inlet is measured in pounds, including the specific gravity and velocity of the fluid.

- Q: How much water does the water ring vacuum pump run for an hour? If there is no steam separator, does the water vaporize?

- Water ring vacuum pump is divided into many types, different sizes, different types, so water is different. As for how much water the no fixed amount, but to ensure that the water temperature is in 25 degrees, not more than 35 degrees can be.

- Q: Variable flow pumps are variable pumps

- Variable input speed, the pump out of the flow is variable, it can not be said that it is variable pump.In a word。 A variable pump is a variable displacement pump.

- Q: The distance from the pump button to the ground

- After confirming that the fire pump has started running, issue a command signal to the hydrant button to light the green answer light.

- Q: What are the basic technical parameters of the pump?

- The effective power of pump and output power, with Pe said. It is the effective energy per unit time from the pump in conveying out liquid obtained in the pump. Because the lift refers to the effective energy, pump output unit of heavy liquid obtained from the pump so that the product of head and the mass flow rate and the acceleration of gravity. Is to obtain the output from the pump in unit time of liquid effective energy - efficient pump power: Pe= P gQH (W) = QH (W) - P - density of liquid pumping (kg/m3); severe gamma - pump for transporting liquid (N/m3) - Q (pump flow; m3/s; H) - pump head (m); G (m/s2). The acceleration of gravity P axle power and effective power Pe is the difference of power loss in the pump, the size of the pump efficiency to measure the efficiency of the pump. As the effective power and shaft power ratio, with ETA said. Selection of related pumps:

- Q: Working principle and structure of external gear pump

- External gear pump is the most widely used gear pump, the general gear pump usually refers to the external gear pump. Its structure as shown in the diagram, there are mainly driving gear, driven gear, pump body, pump cover and safety valve and so on. The seal space of pump body, pump cover and gear is the workshop of gear pump. The wheel shafts of the two gears are respectively arranged in the bearing holes on the two pump cover, and the driving gear shaft extends out of the pump body and is driven by the motor to rotate. The external gear pump is simple in structure, light in weight, low in cost, reliable in operation and wide in application. When the gear pump works, the driving wheel rotates with the motor and drives the driven wheel to rotate

- Q: What is the nominal pressure of the hydraulic pump and hydraulic motor?

- Related concepts of hydraulic motorsFlow theoretical volume refers to the volume of oil inhaled in unit time without leakage.

- Q: Does the control cabinet of the fire control pump need to be related to the fire control room?

- Automatic sprinkler, which is mostly used in this device or high water tank, the whole set of equipment must meet the most unfavorable point (the farthest the highest point of water) water pressure of the faucet.

- Q: What are the differences between the sewage pump and the clean water pump?

- The main difference between the sewage pump and the clean water pump is that:Impeller and runner design, as well as other parts of the configuration are very different.1., in order to prevent clogging of sewage pump, the main design of large flow channel, so naturally lead to relatively low efficiency, so the head is generally not high. Clear water pump flow smaller, smaller clearance, the head is relatively high.

- Q: What is the difference between an air pump and a water pump?

- Pump performance of technical parameters are flow, suction, lift, shaft power, water power, efficiency, etc.; according to the different principles of work can be divided into volume pumps, vane pumps and other types. Displacement pump is to use its studio volume changes to transfer energy; vane pump is to use the rotating blade and water interaction to transfer energy, there are centrifugal pumps, axial flow pumps and mixed flow pumps and other types.

Send your message to us

Horizontal Multistage Designed Stainless Steel Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 2000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches