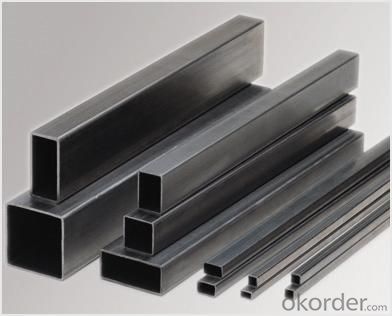

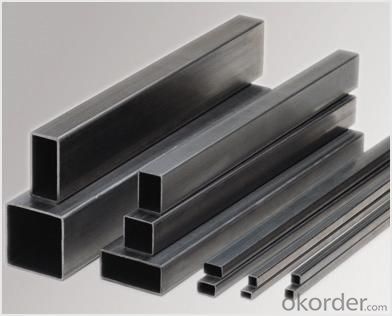

Hollow Section Steel Pipe Construction Steel Section

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 6500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of Hollow Section ASTM A500:

Hollow Section is to be used for . As the manufacturing process are perceived to be stronger and more reliable. Historically pipe was regarded as withstanding pressure better than other types, and was often more easily available than former pipe.

2、Main Features of Hollow Section ASTM A500:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

3、Hollow Section ASTM A500: Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

4) Surface:black lacquered,varnish coating or galvanized.

5) Ends:Beveled or square cut,plastic capped,painted.

6) Packing:bundles wrapped with strong steel strip,seaworthy packing.

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Hollow Section ASTM A500:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

6、 Hollow Section ASTM A500: Images:

- Q: Can steel sheets be used for making shipping containers?

- Yes, steel sheets can be used for making shipping containers. Steel is a commonly used material in the construction of shipping containers due to its strength, durability, and ability to withstand harsh weather conditions.

- Q: Are steel sheets available in textured finishes?

- Yes, steel sheets are available in textured finishes. Textured finishes can be achieved through various processes such as embossing, etching, or brushing. These techniques create patterns or textures on the surface of the steel sheet, giving it a unique and visually appealing appearance. These textured finishes not only enhance the aesthetic appeal of the steel sheet but also provide functional benefits like improved grip, reduced glare, or increased durability. Different types of textures can be applied to steel sheets to suit different applications and design preferences.

- Q: What is the maximum size of the steel sheets available?

- The maximum size of the steel sheets available can vary depending on the specific supplier or manufacturer. Generally, steel sheets can be found in a range of sizes, with widths typically ranging from 36 inches to 72 inches, and lengths ranging from 96 inches to 240 inches. However, it is important to note that these dimensions may vary based on the supplier's capabilities and the specific requirements of the customer. Therefore, it is advisable to contact a supplier or manufacturer directly to inquire about the maximum size of steel sheets they can provide.

- Q: How are steel sheets packaged for shipping?

- Steel sheets are typically packaged for shipping in a way that ensures their protection during transportation. The packaging process involves various steps to prevent any damage or deformation that may occur during transit. Firstly, the steel sheets are usually stacked on wooden pallets or placed in sturdy steel crates. This helps to provide a stable base and prevents any movement or shifting of the sheets during transportation. The use of pallets or crates also makes it easier to load and unload the sheets onto trucks or containers. To further protect the steel sheets from scratches or other forms of surface damage, they are often covered with a layer of protective material. This can include plastic wraps, paper or cardboard interleaves, or even a layer of oil or rust inhibitor. These protective materials act as a barrier between the steel sheets, preventing any direct contact that may cause scratches. Additionally, steel sheets may be bundled together with steel strapping or wire to keep them securely in place. This bundling process helps to maintain the structural integrity of the sheets and prevents them from shifting or sliding during transportation. Finally, once the steel sheets are properly packaged, they are typically labeled with relevant information such as product specifications, quantity, and destination. This ensures that the sheets can be easily identified and handled correctly at each stage of the shipping process. Overall, the packaging of steel sheets for shipping is carefully done to ensure their safe and secure transportation. By using pallets or crates, protective materials, bundling, and labeling, steel sheets can withstand the rigors of shipping and arrive at their destination in optimal condition.

- Q: Are steel sheets suitable for manufacturing water pipes?

- Yes, steel sheets are suitable for manufacturing water pipes. Steel is a durable and strong material that can withstand high pressure and corrosion, making it an ideal choice for water pipe manufacturing.

- Q: Can steel sheets be bent or folded?

- Yes, steel sheets can be bent or folded. Steel is a highly versatile material that can be manipulated into various shapes and forms. In fact, the ability to bend or fold steel sheets is one of the reasons why it is widely used in construction, manufacturing, and other industries. Bending or folding steel sheets can be achieved through different methods such as press braking, roll bending, or using specialized tools like bending machines. The process involves applying force or pressure to the steel sheet, causing it to deform and take on the desired shape.

- Q: Can the steel sheets be easily formed into curves or angles?

- Sheet metal bending is a process commonly employed to shape steel sheets into curves or angles. Specialized tools like brakes or press machines are utilized to achieve the desired form. The capacity to create curves or angles depends mainly on the thickness and type of steel employed. Generally, thinner and more malleable steel sheets are easier to handle and can be molded into tighter curves or angles. Conversely, thicker and less malleable steel sheets might necessitate greater force and advanced machinery to accomplish the desired shape.

- Q: Can steel sheets be used for solar panel installations?

- Yes, steel sheets can be used for solar panel installations. Steel is a strong and durable material that can provide a stable platform for mounting solar panels. It is commonly used in the construction of support structures such as mounting frames or racks for solar panels. Steel sheets can be easily shaped and cut to the desired size, making them suitable for various installation configurations. Additionally, steel is resistant to corrosion, which is important for long-term outdoor use. However, it is crucial to ensure proper insulation and grounding to prevent any electrical issues when using steel sheets for solar panel installations.

- Q: How do steel sheets perform in low-temperature environments?

- In low-temperature environments, steel sheets typically demonstrate excellent performance. The presence of low temperatures does not significantly impact the mechanical properties of steel, such as its strength and toughness. Steel possesses a low coefficient of thermal expansion, which means it does not undergo significant contraction or expansion when exposed to temperature fluctuations. This characteristic enables steel sheets to maintain their shape and structural integrity even in cold conditions. Furthermore, steel exhibits remarkable resistance to brittle fracture at low temperatures. It possesses excellent impact resistance, allowing it to absorb energy without fracturing. As a result, steel sheets are suitable for use in low-temperature environments where materials must endure heavy loads or sudden impacts, such as in cold storage facilities or offshore structures in Arctic regions. It is important to note, however, that certain types of steel, particularly those with high carbon content or low alloy steels, may experience reduced toughness and ductility at extremely low temperatures. In such cases, specific precautions may be necessary. These precautions may include utilizing steel grades specially designed for low-temperature applications or implementing appropriate insulation measures to prevent rapid temperature changes. Overall, steel sheets are generally dependable and exhibit excellent performance in low-temperature environments due to their strength, toughness, and resistance to brittle fracture. Nevertheless, the precise performance of steel in cold conditions may vary depending on the composition and quality of the steel employed.

- Q: Are the steel sheets corrosion-resistant?

- Depending on the steel type and the applied protective coating, steel sheets can exhibit corrosion resistance. Stainless steel sheets, for instance, possess outstanding corrosion resistance due to the presence of chromium, forming a passive protective layer on the surface. Furthermore, galvanized steel sheets are coated with zinc, serving as a sacrificial barrier to safeguard the underlying steel against corrosion. Coatings like painting, powder coating, or plating can also render other types of steel sheets corrosion-resistant. Thus, it becomes crucial to consider the specific steel type and any additional protective measures implemented in order to assess the corrosion resistance of steel sheets.

Send your message to us

Hollow Section Steel Pipe Construction Steel Section

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 6500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords