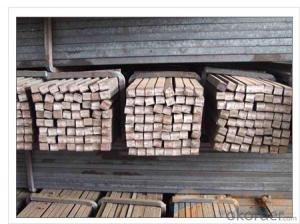

High Quality GB Standard Steel Square Bar 38mm-45mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

We offer Square Steel Bar with grade Q195 / Q235

Specifications of Square Steel Bar:

-Standard: GB,

-Grade: Q195/Q235 or equivalent.

Chemical Composition:

-Chemical Composition. Q195

Standard | Grade | Element (%) | ||||

GB | Q195 | C | Mn | S | P | Si |

0.06~0.12 | 0.25~0.50 | ≤0.050 | ≤0.045 | ≤0.30 | ||

-Chemical Composition. Q235

Standard | Grade | Element (%) | ||||

GB | Q235B | C | Mn | S | P | Si |

0.12~0.20 | 0.30~0.70 | ≤0.045 | ≤0.045 | ≤0.30 | ||

Measures and Tolerances of Square Steel Bar:

(The section of Square Steel Bar)

-The length of a side and the theoretical weight of Square Steel.

Length of a side(a, mm) | Theoretical weight(kg/m) | Length of a side(a, mm) | Theoretical weight(kg/m) |

6 | 0.283 | 32 | 8.04 |

7 | 0.385 | *33 | 8.55 |

8 | 0.502 | 34 | 9.07 |

9 | 0.636 | *35 | 9.62 |

10 | 0.785 | 36 | 10.17 |

11 | 0.950 | 38 | 11.24 |

12 | 1.13 | 40 | 12.56 |

13 | 1.33 | 42 | 13.85 |

14 | 1.54 | 45 | 15.90 |

15 | 1.77 | 48 | 18.09 |

16 | 2.01 | 50 | 19.63 |

17 | 2.27 | 53 | 22.05 |

18 | 2.54 | *55 | 23.6 |

19 | 2.82 | 56 | 24.61 |

20 | 3.14 | *58 | 26.4 |

21 | 3.46 | 60 | 28.26 |

22 | 3.80 | 63 | 31.16 |

*23 | 4.15 | *65 | 33.17 |

24 | 4.52 | *68 | 36.3 |

25 | 4.91 | 79 | 38.49 |

26 | 5.30 | 75 | 44.16 |

*27 | 5.72 | 80 | 50.24 |

28 | 6.15 | 85 | 56.72 |

*29 | 6.60 | 90 | 63.59 |

30 | 7.06 | 95 | 70.85 |

*31 | 7.54 | 100 | 78.50 |

Notes:

1, The theoretical weights in the list, base on the density of 7.85 g/cm3.

2, The numbers with *mean that they are not regulars or we don’t offer them.

-The allowed tolerance of Square Steel:

Length of a side(mm) | Allowed Tolerance | ||

Group1 | Group2 | Group3 | |

5.5~7 | ±0.20 | ±0.30 | ±0.40 |

7~20 | ±0.25 | ±0.35 | ±0.40 |

20~30 | ±0.30 | ±0.40 | ±0.50 |

30~50 | ±0.40 | ±0.50 | ±0.60 |

60~80 | ±0.60 | ±0.70 | ±0.80 |

80~110 | ±0.90 | ±1.0 | ±1.1 |

110~150 | ±1.2 | ±1.3 | ±1.1 |

150~190 | ―― | ―― | ±2.0 |

190~250 | ―― | ―― | ±2.5 |

Usage/Applications of Steel Square Bar:

-The Square Steel is normally used as structure steel.

-Row material for other structure steel like steel angles, channels, I-beams, H-beams, etc…

Packaging & Delivery of Steel Square Bar:

-Packing Detail: The products can be packed in bundles by steel wires.

-Marks:

1, Tag marks: the tag marks will be tied up to each bundle of the products. The information is usually including supplier’s logo and name, product name, made in China, products’ specifications, the painted color and other information requested by customers.

2, Color marks: we will paint both ends of the bundles of these products to make sure that they are more evident. It’s will be more convenient for the customers to distinguish them at the destination port.

-Delivery Detail: 30~45 working days after receive buyer’s T.T. or L/C.

Transportation:

-The products can be delivered by bulk vessel or by container. As for container, products with the length of 6m will be loaded in 20’ container, with 9m or 12m, in 40’ container.

-The maximum quantity of loading of container is 25 tons.

-The products usually are transported to the nearest port from the production place.

- Q: Can a steel square be used for stair railing installation?

- No, a steel square cannot be used for stair railing installation. A steel square, also known as a framing square or carpenter's square, is primarily used for measuring and marking right angles in carpentry and framing work. While it can be useful for other construction tasks, such as laying out cuts or checking for squareness, it is not designed or suitable for installing stair railings. Stair railing installation requires specialized tools and hardware designed specifically for that purpose, such as railing brackets, balusters, and handrail fittings. These components are specifically engineered to meet safety and building code standards, ensuring proper installation and durability. Therefore, it is recommended to use the appropriate railing installation tools, materials, and techniques for a successful and safe stair railing installation.

- Q: 4 x6 1.5 square meters thick, how much money

- 1, the steel prices generally calculated in tons. To see you say the steel is hot dip galvanized or black material.2, hot galvanized general 4500/ tons,3, black wood generally in 3800/ tons.That is 4.5 yuan /kg and 3.8 yuan /kg. Forget it. You say this kind of steel is 2.355kg per meter,

- Q: Are steel squares available in different sizes?

- Yes, steel squares are available in different sizes. Steel squares, also known as engineers' squares or try squares, are typically available in various sizes to cater to different needs and applications. They come in different lengths, commonly ranging from 3 inches to 12 inches or more. The size of a steel square refers to the length of its blade or beam, which is the part used for measuring or marking. The size of a steel square is chosen based on the specific requirements of the task at hand, such as the dimensions of the workpiece or the level of precision desired.

- Q: What are some common uses of a steel square in woodworking joinery?

- A framing square or carpenter's square, commonly referred to as a steel square, is an indispensable tool in woodworking joinery. Its primary functions include measuring, marking, and checking right angles in woodworking projects. Below are several ways in which a steel square is commonly utilized in woodworking joinery: 1. Accurately marking and measuring right angles: The steel square enables precise marking and measurement of 90-degree angles. It aids in drawing square lines, guiding saw cuts, and ensuring meticulous joinery. 2. Verifying squareness: Woodworkers employ a steel square to determine the squareness of joints or corners. By placing the square against the joint or corner, they can swiftly ascertain its perfection or the need for adjustment. 3. Determining and transferring various angles: Steel squares often incorporate additional markings that allow woodworkers to determine and transfer angles other than 90 degrees. This capability proves particularly valuable in creating bevels, mitered corners, and intricate joinery. 4. Layout and marking: Steel squares serve as valuable tools for laying out and marking woodworking project components. They facilitate accurate measurement transfer, marking of cut lines, and precise positioning of joints and connections. 5. Guiding hand saw cuts: Woodworkers often utilize a steel square as a guide to ensure straight and precise cuts with a hand saw. By aligning the square's edge with the cut line, they can maintain a consistent angle and achieve clean, accurate cuts. 6. Verifying flatness: A steel square can also be employed to assess the flatness of a surface or board. Woodworkers can identify any twists, bows, or warping that may impact the overall quality of joinery by placing the square across the wood's width or length. 7. Creating perpendicular lines and notches: The steel square proves highly useful in generating perpendicular lines and notches within woodworking projects. It assists in aligning and marking precise locations for joinery elements such as mortises, tenons, or dovetails. In conclusion, the steel square is an adaptable tool that plays a vital role in guaranteeing accuracy, precision, and quality in woodworking joinery. Its diverse applications render it indispensable for woodworkers at all skill levels, ranging from hobbyists to professionals.

- Q: Can a steel square be used for checking the squareness of a cabinet frame?

- The squareness of a cabinet frame can be checked using a steel square. This versatile tool, also known as a framing square or a carpenter's square, is commonly used in carpentry and construction work. With a 90-degree angle at one end and a 45-degree angle at the other, it is perfect for examining the squareness of objects. To determine if a cabinet frame is square, position the steel square against the frame's edges. The corners of the frame should align perfectly with the 90-degree angle. Any discrepancy or space between the square and the frame signifies that the cabinet frame is not completely square. By utilizing a steel square, the cabinet frame's corners can be guaranteed to be at right angles, ensuring proper assembly and installation. This tool is highly valuable for maintaining accuracy and precision in woodworking projects.

- Q: How accurate are steel squares for measuring?

- Steel squares are renowned for their exceptional accuracy when it comes to measuring angles and lengths. These precision tools are typically crafted from hardened steel, ensuring both stability and durability. When calibrated correctly and used appropriately, steel squares can deliver precise measurements for a diverse array of applications. One of the main advantages of steel squares lies in their ability to maintain accuracy over time. Unlike other materials, steel does not easily warp or deform, guaranteeing reliable and consistent measurements. This stability makes steel squares the preferred choice in numerous industries, including woodworking, metalworking, and construction. Moreover, the edges and surfaces of steel squares undergo precise machining, enabling accurate alignment and marking. The right angles formed by these squares are typically incredibly close to perfect 90-degree angles, rendering them suitable for tasks necessitating precise right angles, such as squaring up corners or assessing machinery accuracy. Nevertheless, it is important to note that the accuracy of steel squares can be affected by factors such as user error, wear and tear, or improper storage. To ensure the utmost accuracy, it is vital to handle steel squares with care and periodically check their calibration using a trustworthy reference square or angle gauge. In conclusion, steel squares are generally considered highly accurate tools for measuring angles and lengths. With their sturdy construction and precise machining, they consistently deliver dependable results. By diligently maintaining and calibrating them, steel squares can be relied upon for a wide range of measurement tasks.

- Q: How do you use a steel square to measure outside corners?

- To use a steel square to measure outside corners, align one arm of the square with one side of the corner and the other arm along the adjacent side. Ensure that the edges of the square are flush with the surfaces being measured. Then, by looking at the markings on the square, you can determine the angle of the corner accurately.

- Q: How do you use a steel square to measure rafter lengths?

- Before you can measure rafter lengths using a steel square, it is important to familiarize yourself with the markings and measurements on the square itself. The square consists of a blade and a tongue, with the blade typically containing different scales and numbers, while the tongue is wider and shorter. When measuring rafter lengths, the blade of the steel square is primarily used. Begin by placing the square on the edge of the rafter board, making sure that the tongue is facing towards the end of the board. Align the end of the board with the zero mark on the blade. Next, identify the scale on the blade that corresponds to the pitch or slope of the roof. These scales are usually denoted in inches and degrees and are essential in determining the length of the rafter. For instance, if the roof pitch is 6/12, utilize the scale marked "6" on the blade. While keeping the tongue pressed against the edge, slide the square along the rafter board. As you move the square, pay close attention to the measurements on the blade. The point at which the desired measurement on the blade aligns with the edge of the board indicates the length of the rafter. To mark this point on the rafter board, use a pencil or a marking tool. Repeat these steps for each rafter, ensuring that you consistently use the same scale on the blade for accurate measurements. Aside from measuring rafter lengths, a steel square possesses various other functions, such as marking angles, making cuts, or checking for squareness. It is a versatile tool that greatly aids in numerous construction and woodworking projects.

- Q: How do you use a steel square to determine angles for picture hanging?

- To use a steel square for determining angles for picture hanging, you can follow these steps: 1. Place the steel square on a flat surface, ensuring that the right-angle corner is facing towards you. 2. Align the bottom edge of the steel square with the wall where you intend to hang the picture. 3. Hold the steel square firmly against the wall, making sure it is level. 4. Use a leveler or a bubble level to ensure that the steel square is perfectly vertical. 5. Once the steel square is in position, you can measure the desired angle by using the markings on the square's blade. 6. Align the top edge of the steel square with the desired angle, making sure it remains level. 7. With the steel square still in place, you can use a pencil or a tape to mark the wall at the desired angle for picture hanging. 8. Remove the steel square and use the marked point as a reference for hanging your picture at the correct angle. By using a steel square, you can obtain accurate and consistent angles for picture hanging, ensuring a visually pleasing display.

- Q: How do you use a steel square to ensure the correct angle for a bridle joint?

- To ensure the correct angle for a bridle joint using a steel square, you would first mark the thickness of the material on both the face and edge of the stock. Then, place the steel square against the edge of the stock and align it with the face mark. Next, transfer the angle by marking a line along the inside edge of the steel square. Repeat this process on the other piece of stock, ensuring that the angle lines up perfectly. This will help create a precise and accurate bridle joint angle.

Send your message to us

High Quality GB Standard Steel Square Bar 38mm-45mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches