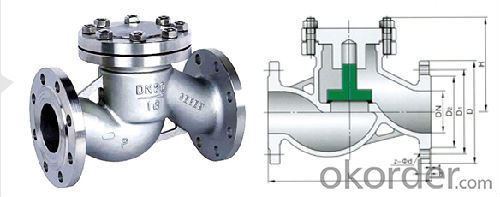

high quality ductile iron cast iron flanged swing check valve

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Quick Details | |||||

| Standard or Nonstandard: | Standard | Structure: | Check | Pressure: | Medium Pressure, 1.0Mpa, 1.6Mpa,2.5Mpa,4.0mpa |

| Power: | Manual | Material: | Casting, cast steel,WCB, stainless steel, ect. | Temperature of Media: | Normal Temperature |

| Media: | Water | Port Size: | DN15-DN300 | Place of Origin: | Tianjin, China (Mainland) |

| Model Number: | Bell | Brand Name: | CMAX | Application: | General |

| Name: | high quality ductile iron cast iron flanged swing check valve | Connection: | Flange | Temperature: | ≤425℃ |

| Standard: | GB,BS,ANSI,JIS,DIN,etc | OEM: | Acceptable | Color: | Customized |

| Certification: | ISO,CE | Warranty: | 12 month |

| Quick Details | |||||

| Standard or Nonstandard: | Standard | Structure: | Check | Pressure: | Medium Pressure, 1.0Mpa, 1.6Mpa,2.5Mpa,4.0mpa |

| Power: | Manual | Material: | Casting, cast steel,WCB, stainless steel, ect. | Temperature of Media: | Normal Temperature |

| Media: | Water | Port Size: | DN15-DN300 | Place of Origin: | Tianjin, China (Mainland) |

| Model Number: | Bell | Brand Name: | CMAX | Application: | General |

| Name: | high quality ductile iron cast iron flanged swing check valve | Connection: | Flange | Temperature: | ≤425℃ |

| Standard: | GB,BS,ANSI,JIS,DIN,etc | OEM: | Acceptable | Color: | Customized |

| Certification: | ISO,CE | Warranty: | 12 month |

Product Feature:

1, the disc lift check valve disc, seat around tunnel axis rotation, due to the channel into a streamline in the valve, flow resistance is smaller than l butterfly check valve, suitable for low velocity and flow not often change the large diameter of occasions, but should not be used for oscillating flow, its sealing performance than lift.Butterfly check valve points single type, double disc type and for the most part three, the three forms mainly by the valve diameter, the purpose is to prevent the backflow medium flow or stop, decrease hydraulic shock.

2, lift check valve: disc revolve around pin in the seat of the check valve.Disc check valve has simple structure, can only be installed in horizontal pipe runs, sealing is good.

3, lift check valve: disc sliding along the center line of the body of the valve.Pipeline check valve is a new kind of valve, its small size, light in weight and good processing technology, is one of the check valve development direction.But the fluid drag coefficient is slightly superior to swing check valves.

| Main performance parameters: | |

| Nominal pressure | PN1.6/2.5/4.0Mpa |

| Suitable temperature | ≤425℃ |

| Applicable medium | Water, oil, gas, corrosive medium, etc |

| Main components | valve body, valve cover, valve, gasket |

| main material | Cast iron, ductile iron, carbon steel, stainless steel |

| Type | DN(mm) | Dimension(mm) | |||||

| L | D | D1 | D2 | z-Φd | H | ||

| HH41W-16Y | 15 | 130 | 95 | 65 | 45 | 4-Φ14 | 90 |

| 20 | 150 | 105 | 75 | 55 | 4-Φ14 | 105 | |

| 25 | 160 | 115 | 85 | 65 | 4-Φ14 | 115 | |

| 32 | 180 | 135 | 100 | 78 | 4-Φ18 | 120 | |

| 40 | 200 | 145 | 110 | 85 | 4-Φ18 | 130 | |

| 50 | 230 | 160 | 125 | 100 | 4-Φ18 | 140 | |

| 65 | 290 | 180 | 145 | 120 | 4-Φ18 | 150 | |

| 80 | 310 | 195 | 160 | 135 | 8-Φ18 | 170 | |

| 100 | 350 | 215 | 180 | 155 | 8-Φ18 | 185 | |

| 125 | 400 | 245 | 210 | 185 | 8-Φ18 | 195 | |

| 150 | 480 | 280 | 240 | 210 | 8-Φ23 | 225 | |

| 200 | 600 | 335 | 295 | 265 | 12-Φ23 | 250 | |

| 250 | 650 | 405 | 355 | 320 | 12-Φ25 | 270 | |

| 300 | 750 | 460 | 410 | 375 | 12-Φ25 | 300 | |

| HH41W-25Y | 15 | 130 | 95 | 65 | 45 | 4-Φ14 | 90 |

| 20 | 150 | 105 | 75 | 55 | 4-Φ14 | 105 | |

| 25 | 160 | 115 | 85 | 65 | 4-Φ14 | 115 | |

| 32 | 180 | 135 | 100 | 78 | 4-Φ18 | 120 | |

| 40 | 200 | 145 | 110 | 85 | 4-Φ18 | 130 | |

| 50 | 230 | 160 | 125 | 100 | 4-Φ18 | 140 | |

| 65 | 290 | 180 | 145 | 120 | 8-Φ18 | 150 | |

| 80 | 310 | 195 | 160 | 135 | 8-Φ18 | 170 | |

| 100 | 350 | 230 | 190 | 160 | 8-Φ23 | 185 | |

| 125 | 400 | 270 | 220 | 188 | 8-Φ25 | 165 | |

| 150 | 480 | 300 | 250 | 218 | 8-Φ25 | 225 | |

| 200 | 600 | 360 | 310 | 278 | 12-Φ25 | 250 | |

| 350 | 650 | 425 | 370 | 335 | 12-Φ30 | 270 | |

| 300 | 750 | 485 | 430 | 390 | 16-Φ30 | 300 | |

| HH41W-40Y | 15 | 130 | 95 | 65 | 45 | 4-Φ14 | 90 |

| 20 | 150 | 1058 | 75 | 55 | 4-Φ14 | 105 | |

| 25 | 160 | 115 | 85 | 65 | 4-Φ14 | 115 | |

| 32 | 180 | 135 | 100 | 78 | 4-Φ18 | 120 | |

| 40 | 200 | 145 | 110 | 85 | 4-Φ18 | 130 | |

| 50 | 230 | 160 | 125 | 100 | 4-Φ18 | 140 | |

| 65 | 290 | 180 | 145 | 120 | 8-Φ18 | 150 | |

| 80 | 310 | 195 | 160 | 135 | 8-Φ18 | 170 | |

| 100 | 350 | 230 | 190 | 160 | 8-Φ23 | 185 | |

| 125 | 400 | 270 | 220 | 188 | 8-Φ25 | 195 | |

| 150 | 480 | 300 | 250 | 218 | 8-Φ25 | 225 | |

| 200 | 600 | 375 | 320 | 282 | 12-Φ30 | 250 | |

| 250 | 650 | 445 | 385 | 345 | 12-Φ34 | 270 | |

| 300 | 750 | 510 | 450 | 408 | 16-Φ34 | 300 | |

- Q: Check valve 1 inches DN25 what do you mean?

- Crown valve pressFirst, an inch equals DN25That is, fixed values to estimate how large a pipeline isOne inch of check valve is mostly copper check valveThe price of I should be around 25 yuan

- Q: Check valve H41T-16. What are the numbers and letters in it?

- H stands for check valve, 4 represents flange 1, and represents form 16 for pressure. This is cast iron lift check valve.Check valve refers to rely on the flow of the media itself and automatically open and close the valve flap, used to prevent media backflow valve, also known as check valve, one-way valve, counter flow valve, and back pressure valve. The check valve belongs to an automatic valve, whose main function is to prevent the backflow of medium, prevent the reverse of pump and drive motor, and release the container medium. Check valve (Check Valve): divided by the structure, can be divided into lift check valve, swing check valve and butterfly check valve three. Lift check valve can be divided into vertical and straight through two. Swing check valve is divided into single, double valve and multi flap type of three. Butterfly check butterfly butterfly, double butterfly, butterfly single, more than a few kinds of check valve, in connection form can be divided into thread connection, flange connection, welding and clamp type connection four kinds.

- Q: What is the difference between the silent check valve and the silent check valve?

- It can be installed horizontally or vertically. The valve is loaded by spring, and its quick closing can effectively eliminate the water hammer. It has good sealing performance and no noise.

- Q: What's the difference between check valves and non-return valves?

- 2, gravity: and spring similar to rely on the valve's own gravity closed to prevent backflow.3, swing type: liquid through the valve body, relying on the pressure to open the side of the rotating valve flap,After the pressure is lost, the disc depends on its back weight and the reverse liquid pressure seals the disc.

- Q: The difference between backflow preventer and check valve

- In abnormal pressure (i.e., the outlet pressure is higher than that of the middle cavity), even if the two check valve can not reverse sealing, safety relief valve can automatically open the reverse water emptying, and the formation of air separation, ensure the health and safety of water upstream.

- Q: What can I do with the lift check valve?

- Standard light valve for you to answer, lift check valve is to rely on the media itself flow and automatically open and close the valve, used to prevent the media back of the valve, also known as check valve, one-way valve, counter flow valve, and back pressure valve.

- Q: Only one is a soft seal and one is hard sealed

- Not the same model. The rubber valve check is HC44X, and the swing check valve is H44H

- Q: What are the types of check valves?

- Taiwan reasonable, this may not have domestic, if you can name, you can call three one-way valve, we can see in accordance with the structure of the spring type.Front Ze valve provides: hope to adopt!!!I hope I can help you.

- Q: Is the overcurrent valve a check valve?

- The overflow valve is just a pipe overflow pronounSuch as decompression, flow valve, butterfly valve, flow valve and so onActually, they are all called in the front wordsTherefore, can not be replaced to illustrate

- Q: What is the HC41X-16Q model of the optical valve? What is its main function?

- Usually the valve is automatically work, fluid pressure flow in one direction, the valve open; the opposite direction of fluid flow by gravity, fluid pressure and valve closing effect on the valve seat, thereby cutting off flow. Not suitable for medium containing solid particles and viscosity. When the medium according to the provisions of the direction of flow, the valve by the media force, is open;

Send your message to us

high quality ductile iron cast iron flanged swing check valve

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords