High Quality 304 Stainless Steel Wire Mesh

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

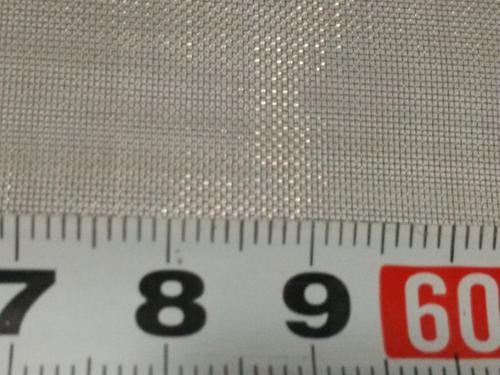

60 Mesh Stainless Steel Wire Mesh

Material: 304 stainless steel wire

Wire DIameter: 0.12mm

Mesh: 60 mesh

Width: 1 m

Length: 30 m/roll

Packing: waterproof paper

MOQ: 1 square meter

Popular Specifications Of Stainless Steel Wire Mesh

- Q: What are the anti-slip properties of steel wire mesh?

- Steel wire mesh has excellent anti-slip properties due to its textured surface and high coefficient of friction. The interwoven wire strands create a rough and stable surface, providing a secure grip for pedestrians and vehicles, even in wet or slippery conditions.

- Q: What are the benefits of using steel wire mesh in the textile industry?

- Steel wire mesh offers several benefits in the textile industry. Firstly, it provides excellent strength and durability, making it ideal for applications that require high tensile strength and resistance to wear and tear. Secondly, the mesh structure allows for proper air circulation, ensuring proper ventilation and preventing the build-up of moisture or heat in textile processes. Additionally, steel wire mesh offers flexibility and versatility, allowing it to be easily shaped and molded to suit various textile manufacturing needs. Lastly, it provides a stable and reliable support system, enabling the production of intricate designs and patterns without compromising the structural integrity of the fabric.

- Q: What is the maximum temperature steel wire mesh can withstand?

- Several factors, such as the grade of steel, wire thickness and quality, and manufacturing process, determine the maximum temperature that steel wire mesh can endure. Typically, steel wire mesh can withstand temperatures ranging from 1000 to 1200 degrees Celsius (1832 to 2192 degrees Fahrenheit) without experiencing noticeable deformation or structural harm. Nevertheless, it should be emphasized that prolonged exposure to high temperatures may gradually diminish the strength and durability of the wire mesh. It is advisable to seek advice from the manufacturer or supplier regarding the specific temperature limits and guidelines applicable to the steel wire mesh in use.

- Q: How is steel wire mesh used in the automotive industry?

- Steel wire mesh is used in the automotive industry for various purposes. It is commonly used in the construction of car grilles and radiator covers to provide protection and ventilation. Additionally, it is used as reinforcement in car seats to enhance comfort and durability. Steel wire mesh is also utilized for reinforcing the body structure and chassis components of vehicles, ensuring strength and safety.

- Q: Is steel wire mesh weather-resistant?

- Yes, steel wire mesh is weather-resistant. Steel wire mesh is typically made from stainless steel or galvanized steel, which are both highly resistant to corrosion and rust. These materials are designed to withstand outdoor elements, including rain, snow, and extreme temperatures. Additionally, steel wire mesh is often coated with a protective layer, such as PVC or epoxy, further enhancing its resistance to weather conditions. This makes steel wire mesh a reliable and durable choice for various applications, including fencing, construction, and filtration systems, in both indoor and outdoor environments.

- Q: How is steel wire mesh used in the textile manufacturing industry?

- Steel wire mesh is commonly used in the textile manufacturing industry as a reinforcing material. It is woven into fabrics to enhance their strength, durability, and dimensional stability. This mesh is particularly useful in applications such as reinforcing seams, reinforcing pockets, adding structure to garments, and providing support in areas that experience high stress.

- Q: How is steel wire mesh used in the food processing industry?

- Steel wire mesh is commonly used in the food processing industry as a versatile material for various applications. It is primarily used for sieving and filtering purposes, ensuring the removal of contaminants and impurities from food products during processing. Steel wire mesh is also used for food packaging, providing a protective barrier while allowing air circulation to prevent moisture buildup. Additionally, it is utilized in conveyor belts, racks, and shelves for efficient storage, transportation, and organization of food items.

- Q: How is steel wire mesh different from other types of wire mesh?

- Steel wire mesh is different from other types of wire mesh due to its unique properties and characteristics. Firstly, steel wire mesh is known for its exceptional strength and durability. It is made from high-quality steel wires that are tightly woven or welded together, creating a sturdy and robust structure. This strength makes steel wire mesh ideal for applications that require high load-bearing capacity or resistance to impacts and abrasion. Secondly, steel wire mesh offers excellent corrosion resistance. The steel used in its construction is often coated with protective materials such as galvanization or stainless steel, which prevent rust and corrosion even in harsh environments. This makes steel wire mesh suitable for outdoor applications or industries that involve exposure to moisture, chemicals, or extreme temperatures. Furthermore, steel wire mesh is highly versatile and can be customized to meet specific requirements. It is available in various mesh sizes, wire diameters, and patterns, allowing for different levels of openness, flexibility, and aesthetic appeal. Steel wire mesh can be further modified through processes like cutting, bending, or shaping to fit specific applications or architectural designs. Lastly, steel wire mesh is widely used in a diverse range of industries and applications. It finds extensive use in construction, infrastructure, mining, agriculture, filtration, and even artistic or decorative purposes. Its versatility, strength, and corrosion resistance make it a preferred choice for many professionals and industries. In summary, steel wire mesh differentiates itself from other types of wire mesh through its exceptional strength, durability, corrosion resistance, versatility, and wide range of applications.

- Q: How does steel wire mesh perform in terms of visibility?

- Steel wire mesh has a relatively low visibility due to its solid structure. While it allows some amount of light to pass through, it may obstruct clear visibility to a certain extent.

- Q: Can steel wire mesh be used for gabion fences?

- Yes, steel wire mesh can be used for gabion fences. It is a common material choice for constructing gabion fences due to its strength, durability, and ability to withstand harsh weather conditions. The steel wire mesh provides stability and structural support to the gabion baskets, which are filled with stones or rocks. This combination creates a sturdy and visually appealing fence solution.

Send your message to us

High Quality 304 Stainless Steel Wire Mesh

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords