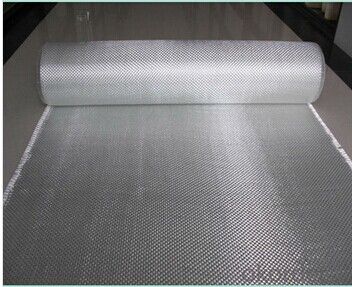

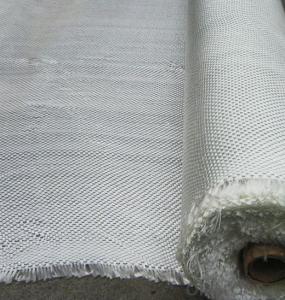

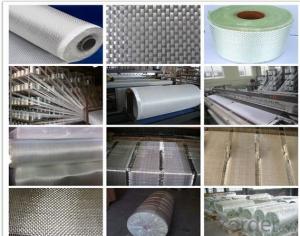

Glass Fiber Textiles Woven Roving Cloth Fabric

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m

- Supply Capability:

- 3000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description

1.Glass woven roving are bidirectional fabric made by direction roving in plain weave pattern.

2.Compatible with unsaturated polyester ,vinyl resin ,epoxy resin .

3.Applicable for hand lay-up ,winding and compress molding process ,suitable for manufacturing tank ,boat ,automobile parts ,and other FRP product

Products advantage

1.Consistent thickness and excellent surface treatment .

2.Rapid impregnating and good compatibility with resin.

3.Uniform tension , high dimensional stability and easy to operate.

4.Good mechanical properties and high strength

5.Factory produce and product ISO certificated

1 Muti-resin-compatible

2 Easy shape adaptation

3 Easy impregnation

4 Good transparency

5 Excellent mechannical properties

product code | area weight | density warp*weft | tex | combustible content |

EWR200 | 200 | 4.6*4.6 | 200*200 | 0.4-0.8 |

EWR 270 | 270 | 4.6*4.1 | 300*300 | |

EWR360 | 360 | 3.2*1.8 | 600*900 | |

EWR400 | 400 | 3.6*3.2 | 600*600 | |

EWR450 | 450 | 3.2*2.8 | 600*900 | |

EWR500 | 500 | 2.2*2.0 | 1200*1200 | |

EWR580 | 580 | 2.6*2.2 | 1200*1200 | |

EWR600 | 600 | 2.6*2.4 | 1200*1200 | |

EWR800 | 800 | 2.0*1.6 | 2400*2400 |

- Q: How do glass fiber textiles affect the breathability of masks or respirators?

- The breathability of masks or respirators can be significantly influenced by glass fiber textiles. These textiles possess exceptional filtration properties, allowing them to effectively capture and block small particles, including airborne contaminants and pathogens. Consequently, they are widely chosen for the production of masks and respirators due to their high level of protection. However, the dense nature of glass fiber textiles can also impede the breathability of masks or respirators. The tightly woven fibers create a barrier that makes it more challenging for air to pass through. Consequently, wearing these masks may result in increased resistance during breathing, making it less comfortable for the wearer. To tackle this issue, manufacturers often integrate additional features into the design of masks or respirators utilizing glass fiber textiles. For example, they may incorporate exhalation valves or vents that facilitate smoother airflow out of the mask, thereby reducing breathing resistance. This ensures a balance between filtration efficiency and breathability. It is crucial to acknowledge that although glass fiber textiles can affect breathability, they play a vital role in delivering effective protection against airborne particles. The filtration capabilities of these textiles are essential in preventing the inhalation of harmful substances. Manufacturers strive to optimize the design and construction of masks or respirators to achieve a harmonious blend of breathability and filtration efficiency, guaranteeing the wearer's comfort and safety.

- Q: Are glass fiber textiles resistant to UV degradation?

- Glass fiber textiles exhibit a high level of resistance to UV degradation. The fibers themselves, being inorganic, do not degrade when exposed to the sun's ultraviolet (UV) radiation. This characteristic makes them well-suited for outdoor applications that involve prolonged exposure to sunlight. Even after extended periods of UV exposure, glass fibers retain their unique properties, such as their strength and durability. Moreover, it is possible to coat glass fiber textiles with materials that are resistant to UV radiation, thereby augmenting their overall ability to withstand UV degradation. This not only extends their lifespan but also enhances their performance in outdoor environments. Considering all these factors, glass fiber textiles are an excellent choice for applications that require protection against UV degradation.

- Q: Can glass fiber textiles be used for making protective helmets or headgear?

- Yes, glass fiber textiles can be used for making protective helmets or headgear. Glass fiber textiles are lightweight yet strong, making them ideal for protective gear such as helmets. The fibers are woven together to create a durable and impact-resistant material that can help absorb and distribute the force of an impact, thereby reducing the risk of head injuries. Additionally, glass fiber textiles have good heat resistance and insulation properties, which further enhance their suitability for headgear. However, it is important to note that helmets and headgear should comply with relevant safety standards and regulations to ensure maximum protection.

- Q: Can glass fiber textiles be used in insulation blankets for cryogenic applications?

- Glass fiber textiles have the ability to be utilized in insulation blankets for cryogenic applications. Their exceptional thermal insulation properties make them appropriate for maintaining extremely low temperatures in such applications. These textiles possess a low thermal conductivity, allowing them to effectively reduce heat transfer and retain the cold temperatures within the insulation blankets. Moreover, glass fiber textiles demonstrate resistance to moisture and exhibit strong mechanical strength, resulting in their durability and long-lasting nature in cryogenic environments. In summary, due to their thermal insulation capabilities and durability, glass fiber textiles are a dependable option for insulation blankets in cryogenic applications.

- Q: Can glass fiber textiles be used in soundproofing?

- Glass fiber textiles have the ability to be utilized in soundproofing. Recognized for their exceptional sound absorption qualities, glass fiber textiles are an ideal material for soundproofing endeavors. They effectively diminish the transmission of sound waves by absorbing and dispersing energy. Glass fiber textiles can be employed in a variety of soundproofing applications, such as wall panels, acoustic ceiling tiles, acoustic curtains, and insulation materials. By absorbing sound waves and preventing them from rebounding off solid surfaces, they effectively lower noise levels within a room, thus creating a more tranquil environment. Moreover, glass fiber textiles are lightweight, easy to install, and provide thermal insulation, making them a versatile option for soundproofing purposes.

- Q: Are glass fiber textiles resistant to discoloration in contact with sweat?

- Yes, glass fiber textiles are generally resistant to discoloration when in contact with sweat.

- Q: Are glass fiber textiles suitable for making carpets or rugs?

- Carpets and rugs are typically crafted from natural or synthetic fibers like wool, nylon, or polyester to ensure comfort and a soft touch. In contrast, glass fiber textiles, despite their exceptional traits like strength, durability, and moisture resistance, lack the necessary qualities to create a pleasant underfoot experience for carpets or rugs. Consequently, glass fiber textiles find more frequent use in applications such as insulation, reinforcement in composites, and as a substitute for asbestos.

- Q: Can glass fiber textiles be used in reinforcement of paper products?

- Yes, glass fiber textiles can be used in the reinforcement of paper products. Glass fiber textiles provide added strength and durability to paper products, making them suitable for applications such as packaging materials, laminates, and specialty papers.

- Q: Are glass fiber textiles resistant to pilling or fuzzing?

- Yes, glass fiber textiles are highly resistant to pilling or fuzzing. Glass fibers are known for their exceptional durability and strength, which means they are less likely to break or wear down over time. Unlike natural fibers such as cotton or wool, glass fiber textiles do not have loose ends or fibers that can become entangled and create pills or fuzz. Additionally, glass fiber textiles have a smooth and non-absorbent surface, which further reduces the likelihood of pilling or fuzzing. Therefore, glass fiber textiles are a great choice for applications where resistance to pilling or fuzzing is required, such as in upholstery, outdoor fabrics, or high-traffic areas.

- Q: How do glass fiber textiles affect tactile comfort?

- Tactile comfort can be influenced by glass fiber textiles in various ways. On the one hand, these textiles can enhance comfort by offering a smooth and soft texture. Weaving or knitting the fibers into a fabric creates a gentle sensation against the skin, providing a pleasant and comfortable feeling. However, there are also drawbacks to consider when it comes to the tactile comfort of glass fiber textiles. If the fibers are not properly treated or the fabric is poorly constructed, they can be sharp and abrasive, causing discomfort and irritation upon direct contact with the skin. Moreover, the heat conductivity of glass fibers can make the fabric feel either cold or hot, depending on the surrounding temperature. In addition, glass fiber textiles have a tendency to trap moisture, which can adversely affect tactile comfort. The accumulation of moisture between the fibers creates a damp and clammy sensation, which can be uncomfortable for the wearer. This issue is particularly problematic in situations where effective moisture management is crucial, such as in sportswear or outdoor clothing. In conclusion, glass fiber textiles can have both positive and negative effects on tactile comfort. While they can offer a smooth and soft texture, they can also be sharp and abrasive if not properly treated. Furthermore, their heat conductivity and moisture trapping tendencies can negatively impact tactile comfort. Therefore, it is essential to carefully consider the specific characteristics and construction of glass fiber textiles when evaluating their influence on tactile comfort.

Send your message to us

Glass Fiber Textiles Woven Roving Cloth Fabric

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m

- Supply Capability:

- 3000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords