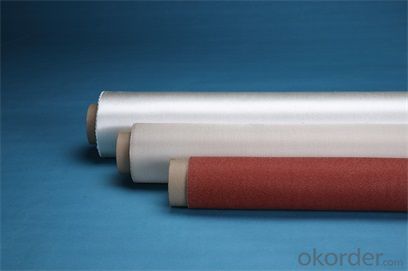

Glass Fiber Textiles - Heat Insulation Fiberglass Cloth for 900C

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Silica fiberglass is inorganic fiber that contents more than 96% of SiO2, it's resistant to high temperature, soft point 1700°C, long term service temperature 900 °C, it can work 10 minites at 1450 °C and keeps good state at 1600 °C for 15 seconds. For it's properties of chemical stability, high temperature resistance and ablation resistance, it widely used in aviationand aerospace, metallurgy, chemical, building material and fire fighting industry, etc.

Our factory is the only one that specialized manufacture silica fiberglass in China and has the production line of the whole process from marble making, fiber forming, weaving, and finish. The strength of silica fiberglass made from Na2O-B2O3-SiO2 system glass is 3-5 times higher than that from E glass. The products sold to more than 20 provinces, cities, autonomous regions and exported to foreign countries.

Silica fiberglass products are available in forms of needled mat, fabric, scrim, staple yarn, chopped strand and cord, etc.

Product Properties

1> SiO2>=96%

2> soft point nearly 1700°C, long-time working at 900°C

3> low thermal conductivity

4> good chemical stability

5> good electrical insulation

6> low thermal shrinkage

7> Non-asbestos product without pollution

8> good process performance

Product Uses

High temperature resistant, insulation and sealing material

High temperature ablation resistant material

Fireproof material (for fireproof protective clothe, fireproof curtain, fire blanket)

Dust collecting in media of high temperature gas and filtration in media of high temperature liquid

Filter for molten metal

Distinguisher, insulation material, filtration of automobile and motorcycle

Protective material for welding

Electricity insulation material

- Q: How do glass fiber textiles perform in terms of stretch and recovery?

- Glass fiber textiles, unlike other synthetic or natural fibers, generally lack the stretch and recovery capabilities. This is due to their inherent brittleness and rigidity, which limits their elasticity and prevents them from stretching and recovering like fabrics made from materials such as spandex or elastane. Glass fibers are more likely to break or deform when exposed to excessive strain or tension. Consequently, glass fiber textiles are not frequently employed in applications where stretch and recovery properties are crucial, such as activewear or garments that require flexibility.

- Q: How do glass fiber textiles contribute to moisture resistance?

- Glass fiber textiles contribute to moisture resistance through their inherent properties. Glass fibers are made from a non-absorbent material, meaning they do not readily soak up or retain moisture. This helps to prevent water from seeping through the textile and reaching the underlying materials or surfaces. Additionally, glass fiber textiles are often woven or knitted into a tight and dense structure, which creates a barrier against moisture. The interlocking fibers form a physical barrier that prevents water molecules from passing through, thereby enhancing the moisture resistance of the textile. Moreover, glass fibers are highly resistant to mold and mildew growth, which can be triggered by moisture. This resistance is due to the inorganic nature of glass fibers, as mold and mildew typically thrive on organic materials. By inhibiting the growth of these microorganisms, glass fiber textiles help to maintain a dry and moisture-free environment. Furthermore, glass fiber textiles can be treated with water-repellent coatings or finishes to enhance their moisture resistance. These coatings create a hydrophobic surface, causing water to bead up and roll off the textile rather than being absorbed. This additional layer of protection further improves the moisture resistance of glass fiber textiles. In summary, glass fiber textiles contribute to moisture resistance through their non-absorbent nature, dense structure, resistance to mold and mildew, and the potential for water-repellent coatings. These properties make glass fiber textiles an excellent choice for applications where moisture resistance is crucial, such as in outdoor clothing, upholstery, or building materials.

- Q: Can glass fiber textile be used in solar panels?

- Glass fiber textile is indeed suitable for utilization in solar panels. Possessing outstanding electrical insulation properties, this lightweight and flexible material can serve as a substrate or backing for solar panels, providing valuable structural support and safeguarding the fragile solar cells. By incorporating glass fiber textile, the longevity of solar panels is enhanced, as it resists weathering, moisture, and UV radiation. Furthermore, the flexibility of glass fiber textile facilitates seamless integration into diverse solar panel designs, offering increased installation options. Consequently, the utilization of glass fiber textile in solar panels contributes significantly to their overall efficiency and durability.

- Q: Are glass fiber textiles resistant to breaking under tension?

- Yes, glass fiber textiles are generally resistant to breaking under tension. Glass fibers are known for their high tensile strength, meaning they can withstand a significant amount of pulling or stretching force before breaking. This makes them highly reliable in applications where strength and durability are required, such as in the manufacturing of reinforcement materials for composites, insulation, and protective clothing. Additionally, the inherent properties of glass fibers, such as their low thermal expansion and resistance to chemicals, further contribute to their ability to resist breaking under tension.

- Q: Can glass fiber textiles be used for making tents or shelters?

- Yes, glass fiber textiles can be used for making tents or shelters. Glass fiber textiles, also known as fiberglass textiles, are lightweight, durable, and have excellent resistance to heat, fire, and chemicals. These properties make them suitable for various applications, including tents and shelters. Glass fiber textiles can be used to create tent fabrics that are both strong and flexible. They can provide protection from external elements such as rain, wind, and UV radiation. The materials are also resistant to mold, mildew, and insect damage, making them ideal for long-term outdoor use. Additionally, glass fiber textiles offer good insulation properties, helping to maintain a comfortable temperature inside the tent or shelter. They can prevent heat loss in cold conditions and minimize heat gain during hot weather. Furthermore, glass fiber textiles are easy to clean and maintain. They can be washed, dried, and stored without losing their structural integrity or functional properties. This makes them a practical choice for camping or emergency shelters that require frequent use and transportation. In summary, glass fiber textiles are a viable option for making tents or shelters due to their lightweight, durability, resistance to external elements, insulation properties, and ease of maintenance.

- Q: How do glass fiber textiles affect energy efficiency?

- Glass fiber textiles can significantly improve energy efficiency in various ways. Firstly, they have excellent insulation properties, which means they can effectively trap heat or cold air inside a building, reducing the need for excessive heating or cooling. This insulation capability can lead to substantial energy savings and lower utility bills. Additionally, glass fiber textiles can also act as a barrier against drafts or air leakage, preventing heat loss or gain from the outside environment. By minimizing the transfer of thermal energy, these textiles contribute to maintaining a comfortable indoor temperature and reducing the reliance on heating or cooling systems. Overall, glass fiber textiles play a crucial role in enhancing energy efficiency by providing effective insulation and reducing energy consumption in buildings.

- Q: Are glass fiber textiles resistant to chemical spills?

- Yes, glass fiber textiles are generally resistant to chemical spills due to their non-reactive nature and high chemical resistance.

- Q: How is glass fiber made?

- Glass fiber, also known as fiberglass, is made through a process called fiberization. The process begins with the raw material, which is usually silica sand, but can also include other additives like limestone or alumina. These raw materials are melted in a furnace at a temperature of around 1500°C (2732°F) until they become a molten liquid. Once the molten glass is formed, it is then forced through tiny holes in a device called a bushing. This bushing contains hundreds or even thousands of small holes, each around 10-25 micrometers in diameter. As the molten glass is pushed through these holes, it is rapidly cooled by either air or water jets. This rapid cooling solidifies the molten glass into thin strands or fibers. The fibers are then collected and wound onto spools or gathered into mats, depending on the desired final product. These fibers can be further processed to give them specific properties. For instance, they can be coated with a sizing material to improve their compatibility with resins or other materials they will be used with. The resulting glass fibers are strong, lightweight, and resistant to heat, chemicals, and electricity. They are widely used in various industries, such as construction, automotive, aerospace, and even in everyday household items. Glass fiber-reinforced plastics (GRP) and glass wool insulation are some common applications of glass fiber. In summary, glass fiber is made by melting raw materials, forcing the molten glass through tiny holes to form fibers, and then cooling and collecting these fibers for further processing. This manufacturing process allows for the production of versatile and durable fibers that are essential in many modern applications.

- Q: How durable are glass fiber textiles?

- Glass fiber textiles are known for their exceptional durability. The fibers themselves are made from glass, which is inherently strong and resistant to wear and tear. This makes glass fiber textiles highly durable and able to withstand various environmental conditions and physical stresses. Glass fiber textiles are also resistant to chemicals, abrasion, and UV radiation. They do not degrade easily when exposed to harsh chemicals or sunlight, making them suitable for use in outdoor applications. Additionally, glass fibers have a high melting point, which means they can withstand high temperatures without losing their structural integrity. Furthermore, glass fiber textiles have excellent tensile strength, meaning they can resist stretching and breaking under tension. This property makes them ideal for applications where strength and durability are important, such as in the construction industry for reinforcing concrete or in manufacturing composite materials. Overall, glass fiber textiles are known for their exceptional durability, making them a reliable choice for a wide range of applications that require strength, resistance to chemicals and UV radiation, and the ability to withstand various environmental conditions.

- Q: Can glass fiber textiles be used in composites?

- Yes, glass fiber textiles can be used in composites. Glass fiber textiles, also known as fiberglass textiles, are commonly used as reinforcement materials in composite manufacturing. They are made by weaving or knitting glass fibers together, resulting in a strong and lightweight material. Glass fiber textiles are widely used in industries such as aerospace, automotive, construction, and marine, where high strength-to-weight ratio and corrosion resistance are required. In composites, glass fiber textiles are often combined with a matrix material, such as epoxy or polyester resin, to create a composite structure. The glass fibers provide strength and stiffness to the composite, while the matrix material holds the fibers together and protects them from external forces. This combination results in a material that is stronger and more durable than either the glass fibers or the matrix material alone. Glass fiber textiles can be used in a variety of composite applications, including structural components, panels, pipes, tanks, and even consumer products like sporting goods and electronics. They offer excellent mechanical properties, such as high tensile strength, impact resistance, and dimensional stability. Additionally, glass fiber composites can be tailored to meet specific requirements by adjusting the fiber orientation, thickness, and resin formulation. Overall, glass fiber textiles are a versatile and widely used reinforcement material in composites due to their excellent mechanical properties, corrosion resistance, and cost-effectiveness.

Send your message to us

Glass Fiber Textiles - Heat Insulation Fiberglass Cloth for 900C

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords