Glass Fiber Reinforced Microporous Calcium Silicate Insulation Board

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for Micropore Insulation Board ,Heat Insulation materials

| Type: | Other Heat Insulation Materials | Place of Origin: | China (Mainland) | Brand Name: | |

| Model Number: | HCS | Color: | white | Apparent Density: | 220 +/- 10% |

| Heat Conductivity: | 0.060 | Highest Working Temperature: | 1050 | Material: | Xonotlite and reinforced glass fiber |

Packaging & Delivery

| Packaging Details: | Standard Fumigation Wooden pallet or Carton Package with Plastic Sheet inside |

| Delivery Detail: | Generally within 2 weeks after receipt of deposit |

Specifications

Microporous calcium silicate insulation board

experienced manufacturer

Size:1000*600mm,600*150mm

ISO9001:2008

Microporous calcium silicate insulation board

It is mixed with Xonotlite and reinforced glass fibre with high service temp. (1050 celsius),good heat insulation, low bulk density, high strength, good durability and so on.

Product characteristics:

² Good durability, can bear high temperature within the limit of continuous heat load,

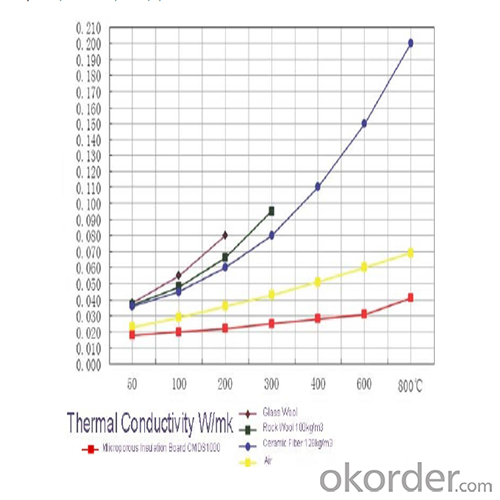

² Low thermal conductivity, in the whole range are used with unmatched adiabatic performance.

² Light weight, high strength. It is the highest in these hard thermal insulation products.

² Better durability, use for a long time without powder.

² Construction with ordinary carpenter applicability, tools can be optional cut products.

² Used safety, hygiene. Excluding asbestos, sulfur, chlorine such poisonous substances.

² Fear water, but after drying also can be used.

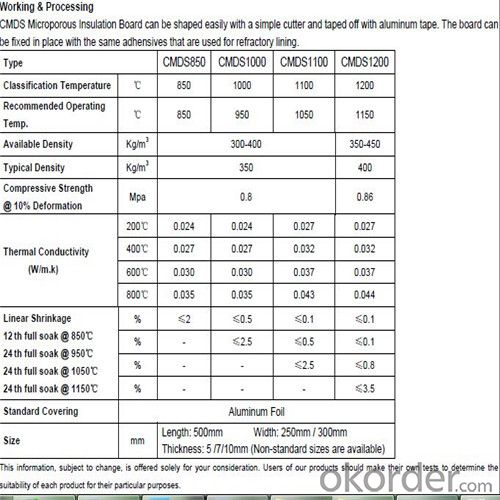

HCS Physical Performance Index

Items | Unit | HCS-170 | HCS-220 | HCS-270 |

Bulk Density | Kg/m3 | 170(±10%) | 220(±10%) | 270(±10%) |

Pressure Strength | MPa | ≥0.40 | ≥0.50 | ≥0.60 |

Flexural Strength | MPa | ≥0.30 | ≥0.35 | ≥0.40 |

Thermal Conductive | W/m.k | ≤0.048 +0.00011t | ≤0.050 +0.00011t | ≤0.056 +0.00011t |

Temp. limit | degrees | 1000 | 1050 | 1050 |

Linear Shrinkage | % | ≤1.50 (1000,3hrs) | ≤1.50 (1000,3hrs) | ≤1.50 (1000,3hrs) |

Block Sizes and Dimensional Tolerances

Length(±3mm) | Width(±3mm) | Thickness(+2mm,—1.5mm) |

610 | 303,300,150 | 25—140 |

600 | 300 | 25—140 |

400 | 250 | 25—140 |

1000 | 500 | 25—140 |

1200 | 600 | 25—140 |

We also supply special size and type.

Standard Dimension:

1000(900)×600(500)×5-20mm

We can also manufacture the special dimensions as customers need.

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Which payment terms can you accept?

A:T/T,L/C,Western Union,Moneygram,Paypal are available for us.

Q5:After an order is confirmed,when to deliver?

A:15-25days after deposit.

Q6:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q7:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q8:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q9:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q10:What is the service life of your bricks?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

Thanks for your coming in,if there is any question,I will be glad to help you.

- Q: Can glass fiber textiles be used for filtration purposes?

- Indeed, filtration purposes can be served by glass fiber textiles. The exceptional filtration properties of glass fiber textiles are attributed to their remarkable porosity and fine pore size. These textiles possess the capability to successfully trap and eliminate a wide range of impurities, including dust, particles, and even microorganisms, from fluids or gases. In numerous sectors, such as air filtration systems, water treatment plants, and laboratory applications, glass fiber filters are extensively employed. Their capacity to withstand high temperatures, their chemical stability, and their mechanical robustness render them a suitable preference for demanding filtration needs. In conclusion, glass fiber textiles are an assured and effective alternative when it comes to filtration purposes.

- Q: How do glass fiber textiles compare to carbon fiber textiles?

- Both glass fiber textiles and carbon fiber textiles are widely used in various industries due to their high strength and lightweight properties. However, there are several key distinctions between these two materials. To begin with, glass fiber textiles are created by weaving together fine strands of glass, resulting in a fabric. They are renowned for their exceptional thermal insulation properties and find common applications in insulation, filtration, and reinforcement in construction materials. Glass fiber textiles are generally more cost-effective in comparison to carbon fiber textiles. On the contrary, carbon fiber textiles are formed by bonding carbon atoms in a crystal alignment, resulting in an incredibly strong and lightweight material. Carbon fiber textiles possess a higher tensile strength than glass fiber textiles, making them suitable for high-performance applications such as aerospace, automotive, and sports equipment. Furthermore, they display excellent resistance to chemical corrosion and can withstand high temperatures. Another crucial distinction lies in the stiffness and flexibility of these materials. Carbon fiber textiles exhibit higher stiffness, providing greater structural integrity and rigidity. Glass fiber textiles, although still robust, are more flexible and can be molded into intricate shapes. This flexibility renders them more suitable for applications requiring bending or shaping. Regarding weight, carbon fiber textiles are significantly lighter than glass fiber textiles. This weight advantage contributes to enhanced fuel efficiency in transportation applications and enables faster and more agile sports equipment. In conclusion, while glass fiber textiles excel in thermal insulation and affordability, carbon fiber textiles offer superior strength, stiffness, and lightweight properties. The choice between these two materials depends on the specific requirements of the application, with carbon fiber textiles being preferred in industries that prioritize high-performance and lightweight characteristics.

- Q: Can glass fiber textiles be used in soundproofing?

- Yes, glass fiber textiles can be used in soundproofing. Glass fiber textiles are known for their excellent sound-absorbing properties, making them an ideal material for soundproofing applications. They can effectively reduce the transmission of sound waves by absorbing and dissipating the energy. Glass fiber textiles can be used in various soundproofing applications such as wall panels, acoustic ceiling tiles, acoustic curtains, and insulation materials. They are capable of reducing the noise levels in a room by absorbing the sound waves and preventing them from bouncing off hard surfaces, thus creating a quieter environment. Additionally, glass fiber textiles are lightweight, easy to install, and provide thermal insulation as well, making them a versatile choice for soundproofing purposes.

- Q: How are glass fiber textiles different from other types of textiles?

- Glass fiber textiles distinguish themselves from other textiles primarily due to their composition. While most textiles are made from natural fibers like cotton, silk, or wool, glass fiber textiles are comprised of synthetic fibers made of glass. The primary distinction between glass fiber textiles and other textiles lies in their strength and durability. Glass fibers possess high tensile strength, enabling them to endure substantial tension without breaking. This quality renders glass fiber textiles ideal for applications necessitating strength and stability, such as reinforcement materials in composites or industrial fabrics. Additionally, glass fiber textiles exhibit exceptional heat resistance. Unlike natural fibers that can burn or melt under high temperatures, glass fibers maintain their structural integrity when exposed to extreme heat. Consequently, glass fiber textiles are suitable for usage in high-temperature environments, such as insulation materials or protective clothing for firefighters. Another notable difference is the transparency of glass fiber textiles. Due to the nature of the glass material, these textiles can be manufactured to possess varying degrees of transparency or translucency. This feature renders them suitable for applications like window coverings or curtains where controlled light transmission is desired. Furthermore, glass fiber textiles demonstrate high resistance to chemical corrosion. They remain unaffected by most chemicals, acids, or alkalis, making them a preferred choice in industries like chemical processing or wastewater treatment. Nevertheless, it is important to acknowledge that glass fiber textiles may not offer the same level of comfort or flexibility as natural fiber textiles. Due to their synthetic nature, glass fibers can be rigid and less breathable. Consequently, they are less suitable for applications such as clothing or bedding, where comfort and softness are crucial factors. In conclusion, glass fiber textiles possess unique properties that differentiate them from other textile varieties. Their strength, heat resistance, transparency, and chemical resistance make them invaluable for a wide range of industrial and specialized applications.

- Q: Are glass fiber textiles suitable for making carpets or rugs?

- Yes, glass fiber textiles are suitable for making carpets or rugs.

- Q: What are the different bonding methods for glass fiber textile?

- There are several different bonding methods for glass fiber textile, each with its own unique advantages and applications. 1. Adhesive bonding: This method involves using a specific adhesive to bond the glass fibers together. The adhesive is typically applied to the fabric and then cured to create a strong and durable bond. Adhesive bonding is commonly used in applications where flexibility and strength are required, such as in the manufacturing of sports equipment or automotive parts. 2. Heat bonding: Also known as thermal bonding, this method involves using heat to melt the fibers together, creating a solid bond. Heat bonding is often used for joining two or more layers of glass fiber fabric together to create a thicker and stronger material. It is commonly used in the production of laminated glass fiber composites. 3. Stitch bonding: This method involves using stitching or sewing to bond the glass fibers together. A needle and thread are used to sew the fibers together, creating a strong and durable bond. Stitch bonding is often used in applications where flexibility and breathability are important, such as in the manufacturing of clothing or upholstery. 4. Weaving: This method involves interlacing the glass fibers together to create a fabric. The fibers are woven using a loom, where they are crossed over and under each other to form a stable structure. Weaving is commonly used in the production of glass fiber textiles, such as fiberglass cloth or fiberglass tape. 5. Knitting: This method involves interlocking loops of glass fibers to create a fabric. Knitting machines or hand knitting needles are used to create the loops, which are then secured together to form a cohesive fabric. Knitting is often used in the production of glass fiber garments or accessories, as it provides a stretchy and comfortable material. Overall, the choice of bonding method for glass fiber textile depends on the specific requirements of the application, such as strength, flexibility, or breathability. Each method has its own advantages and limitations, and manufacturers will choose the most suitable method based on the desired properties of the final product.

- Q: How do glass fiber textiles contribute to chemical resistance?

- Glass fiber textiles contribute to chemical resistance through their inherent properties and manufacturing processes. Firstly, glass fibers themselves are highly resistant to many chemicals. This is due to the fact that glass is an amorphous material, meaning it does not have a regular crystalline structure. This lack of structure makes glass fibers less susceptible to chemical attack and degradation compared to other textile materials such as natural fibers or synthetic polymers. Furthermore, glass fiber textiles can be manufactured with different types of glass, each offering specific chemical resistance properties. For example, E-glass is commonly used for general chemical resistance, while C-glass provides enhanced resistance to alkali chemicals. By carefully selecting the glass composition, manufacturers can tailor the textile's resistance to specific chemicals or environments. The manufacturing process of glass fiber textiles also plays a role in their chemical resistance. During production, the glass fibers are typically coated or impregnated with various types of chemical-resistant finishes or coatings. These finishes can provide additional protection against chemical attack, making the textile even more resistant to corrosive substances. In addition to their inherent chemical resistance and manufacturing processes, glass fiber textiles also offer other advantages that contribute to their chemical resistance. They have high tensile strength and dimensional stability, allowing them to resist physical stress and maintain their shape even when exposed to harsh chemicals. Glass fibers are also non-flammable and have low thermal conductivity, making them suitable for applications involving high temperatures or fire hazards. Overall, glass fiber textiles contribute to chemical resistance through their inherent properties, manufacturing processes, and additional finishes or coatings. They provide a durable and reliable solution for applications where protection against chemical corrosion is essential.

- Q: Can glass fiber textile be used in furniture?

- Yes, glass fiber textile can be used in furniture. It is a versatile material that offers several benefits such as strength, durability, and resistance to heat and moisture. Glass fiber textile can be used in various furniture components like upholstery, cushions, and reinforcement structures, providing added support and longevity to the furniture.

- Q: Can glass fiber textile be used in sporting goods?

- Yes, glass fiber textile can be used in sporting goods. Glass fiber textiles are lightweight, strong, and have excellent impact resistance, making them suitable for various applications in the sports industry. They are commonly used in the manufacturing of sports equipment such as tennis rackets, golf club shafts, hockey sticks, and bicycle frames. The use of glass fiber textiles in sporting goods helps enhance performance, increase durability, and improve overall safety for athletes.

- Q: Are glass fiber textiles resistant to wrinkling?

- Yes, glass fiber textiles are generally resistant to wrinkling. Glass fibers are known for their inherent strength and rigidity, which helps to maintain the shape and structure of textiles made from them. Additionally, glass fibers have a low coefficient of thermal expansion, meaning they do not expand or contract significantly with changes in temperature, further contributing to their wrinkle-resistant properties. This makes glass fiber textiles highly durable and less prone to wrinkling compared to other materials. However, it is important to note that the overall wrinkle resistance of a textile can also depend on factors such as the specific weave or construction of the fabric, as well as the finishing treatments applied to it.

Send your message to us

Glass Fiber Reinforced Microporous Calcium Silicate Insulation Board

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords